4

...1.4 Installation

Environmental Protection – The approval permits

installation below ground level where provision has

been made to prevent flooding. However to

accommodate accidental flooding (e.g. following a

pump failure) or if moisture ingress is possible, the

sensor connection box must be potted as soon as

connections are completed. Potting is supplied.

For a dry location with no possibility of flooding, it

is recommended that the unit is not potted.

Information. Certification does not apply to

submerged or buried sensors.

…1 CENELEC/ATEX APPROVED FLOWMETERS

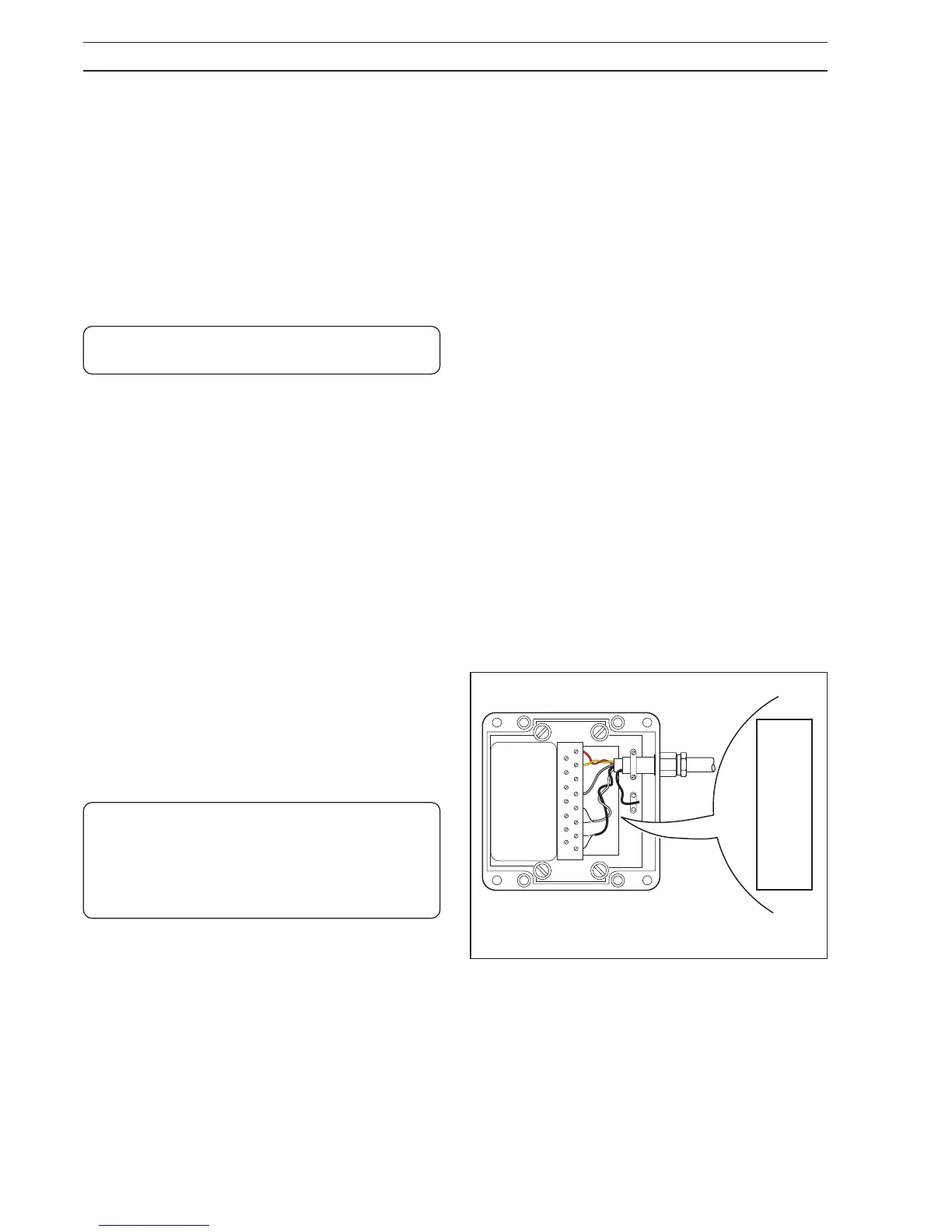

1.4.1 Sensor Box Wiring

The wiring details (see below) are, in general, the

same as the standard (non-Hazardous Area)

remote version. However since the safety of the

system depends upon reliable connections, the

following points must be observed:

• Prepare cables with care as shown in the

installation manual except that bared cable

ends must be 10mm long, and not 5mm as for

the standard version.

• Remove all wire cuttings.

• Note routing of outer screen earth drain wire

(see illustration below).

• Sleeve all exposed conductors.

• Fully insert wires into terminal blocks up to the

insulation.

• Ensure that terminals, cable clamps, glands

etc. are fully tightened.

Caution. The sensor connection box

contains low value fuses. Under no

circumstances should low impedance

voltage be applied or electrode cleaning be

attempted.

CD1

CD2

SIG GND

DS1

SIG1

SIG2

DS2

CD1

CD2

–––

SIG GND

DS1

SIG1

SIG2

DS2

1.5 Safety of Pressurised Flowlines

If the flowmeter is to operate at significantly more

than one bar, see the following EECS Newsletter

extract.

The extract applies to any electromagnetic

flowmeter operated above atmospheric pressure.

It is not a limitation on the use of the equipment so

much as a limitation of the approval standards, If

the plant is deemed unconditionally safe by the

following criteria then the contents of the

newsletter do not apply.

System is Unconditionally Safe if:

• Operation is nominally 1 bar.

• Pipeline is operated with no explosive gas

mixture.

• Pipeline is full of liquid, at any rated pressure.

• Pipeline is reduced to atmospheric pressure

before being allowed to drain.

• Pipeline is vented or depressurised, whether

empty, full or partly full.

• Transmitter is working normally.

• Transmitter is switched off.

Recommendation – Mount sensor in a low part of

pipe run, i.e. pipe normally full.

Fig. 1.1 Sensor Box Wiring

Loading...

Loading...