PositionMaster EDP300 | CI/EDP300-EN Rev. C 27

6.7.2 Connection on the device

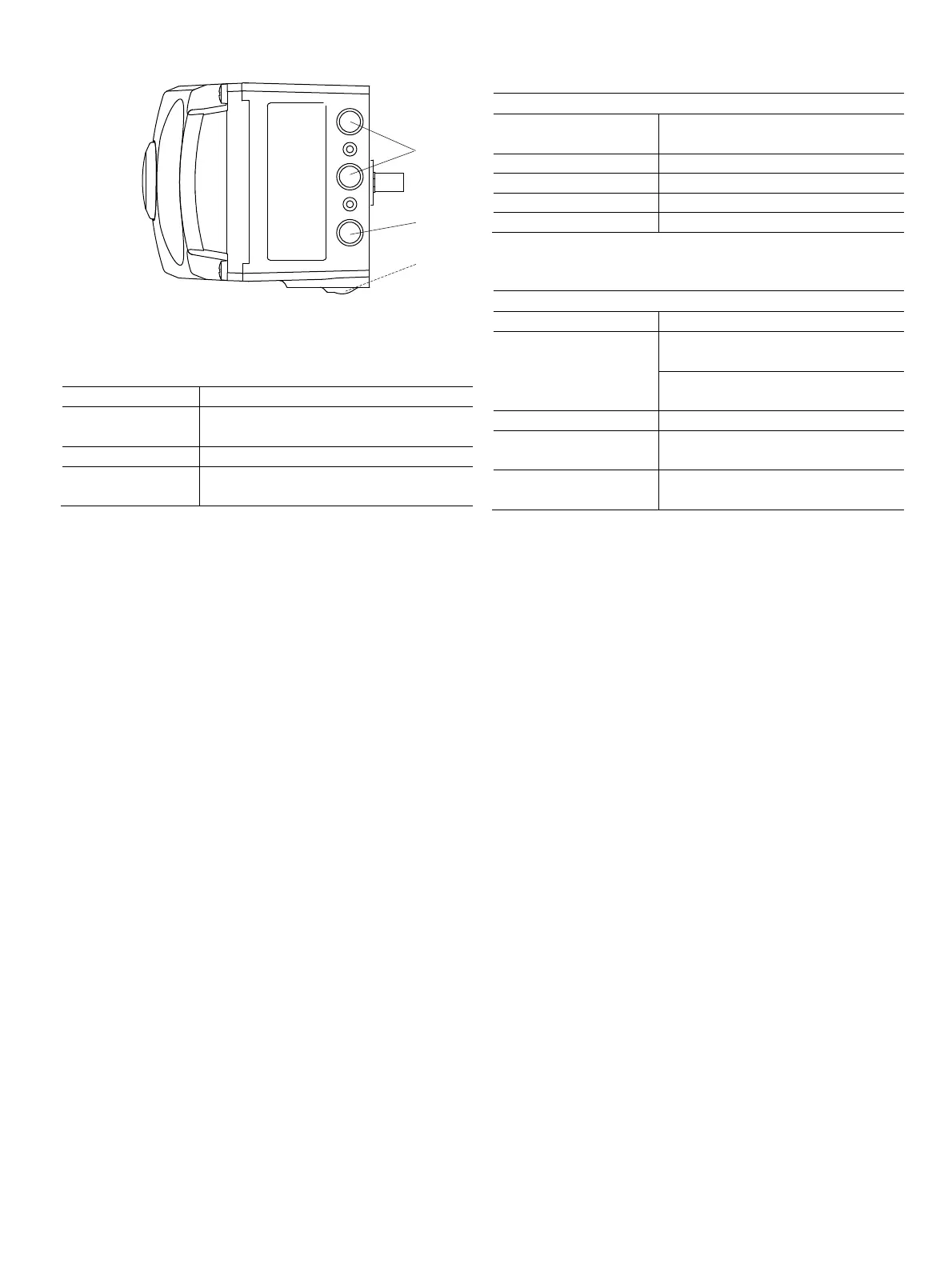

M10132-01

2

3

NPT1/4"

G1/4"

Y2

OUT 2

Y1

OUT 1

SUP/ZUL

IN

1

Fig. 26: Pneumatic connections

1 Pneumatic outputs 2 Supply air

3 Filter screw (on underside of housing)

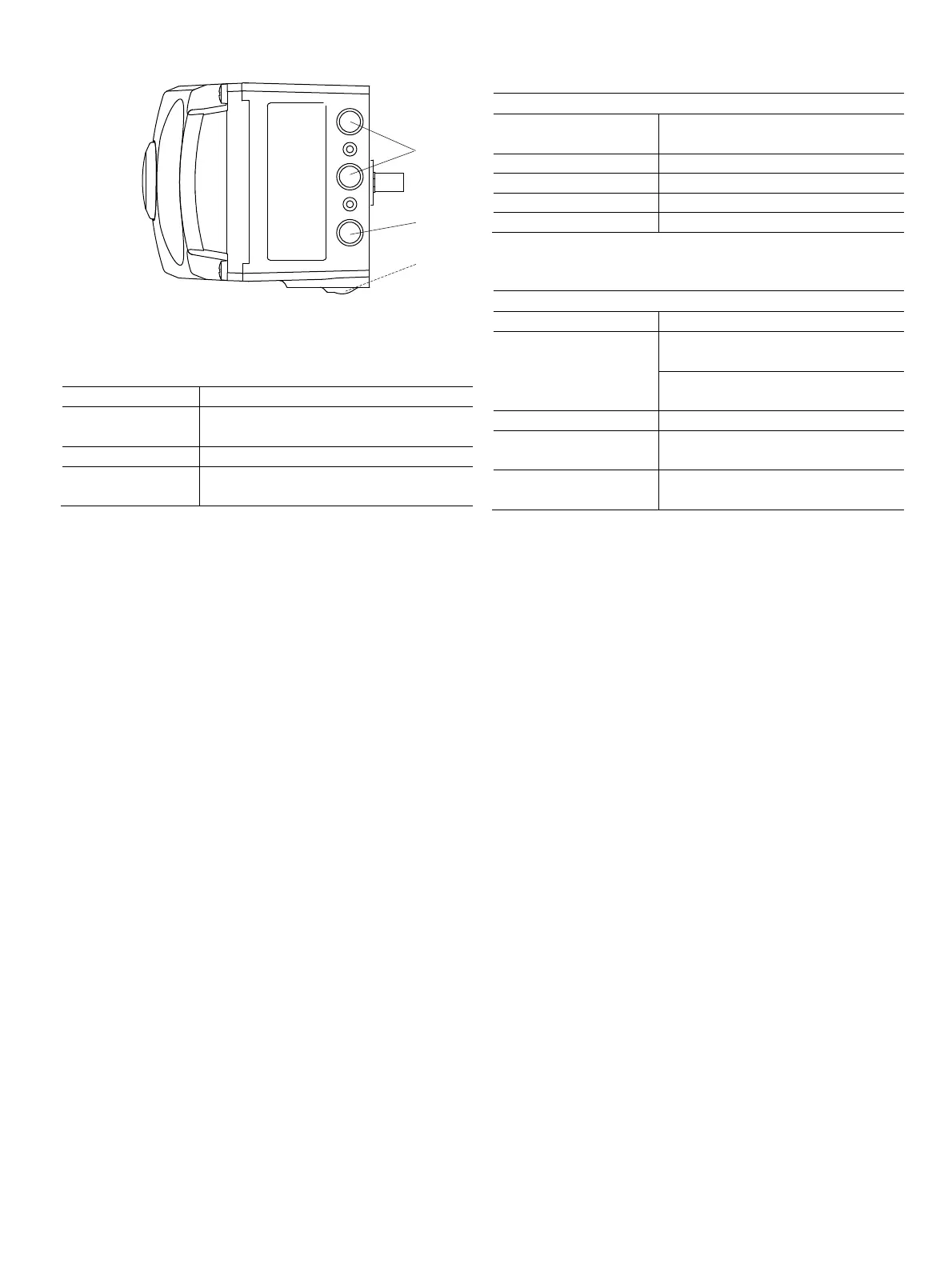

Marking Pipe connection

SUP / ZUL IN Supply air, pressure 1.4 ... 10 bar (20 ... 145

psi)

Y1 / OUT1 Output pressure for actuator

Y2 / OUT2 Output pressure for actuator (2nd connection

with double-acting actuator)

Join the pipe connections according to the designation,

observing the following points:

— All pneumatic piping connections are located on the right-

hand side of the positioner. G1/4 or 1/4 18 NPT tap holes

are provided for the pneumatic connections. The

positioner is labeled according to the tap holes available.

— We recommend that you use a line with dimensions of 12

x 1.75 mm. The level of supply air pressure required to

apply the actuating force must be adjusted in line with the

output pressure in the actuator.

— The working range for the positioner is between

1.4 ... 10 bar (20 ... 145 psi).

6.7.3 Air supply

Instrument air

1)

Purity Maximum particle size: 5 m

Maximum particle density: 5 mg/m

3

Oil content Maximum concentration 1 mg/m

3

Pressure dew point 10 K below operating temperature

Supply pressure 1.4 … 10 bar (20 … 145 psi)

Air consumption

2)

< 0.03 kg/h / 0.015 scfm

1) Free of oil, water and dust in accordance with DIN / ISO 8573-1. Pollution and

oil content according to Class 3

2) Independent of supply pressure

Compressed air output

Range 0 ... 10 bar (0 ... 145 psi)

Air capacity Standard:

40 kg/h = 31 Nm

3

/h = 20 scfm

Optional:

50 kg/h (40 Nm

3

/h / 23 scfm)

Output function For single or double-acting actuators

Air is vented from actuator or actuator is

blocked in case of (electrical) power failure

Shut-off values

End position 0 % = 0 ... 45 %

End position 100 % = 55 ... 100 %

Loading...

Loading...