27

EN

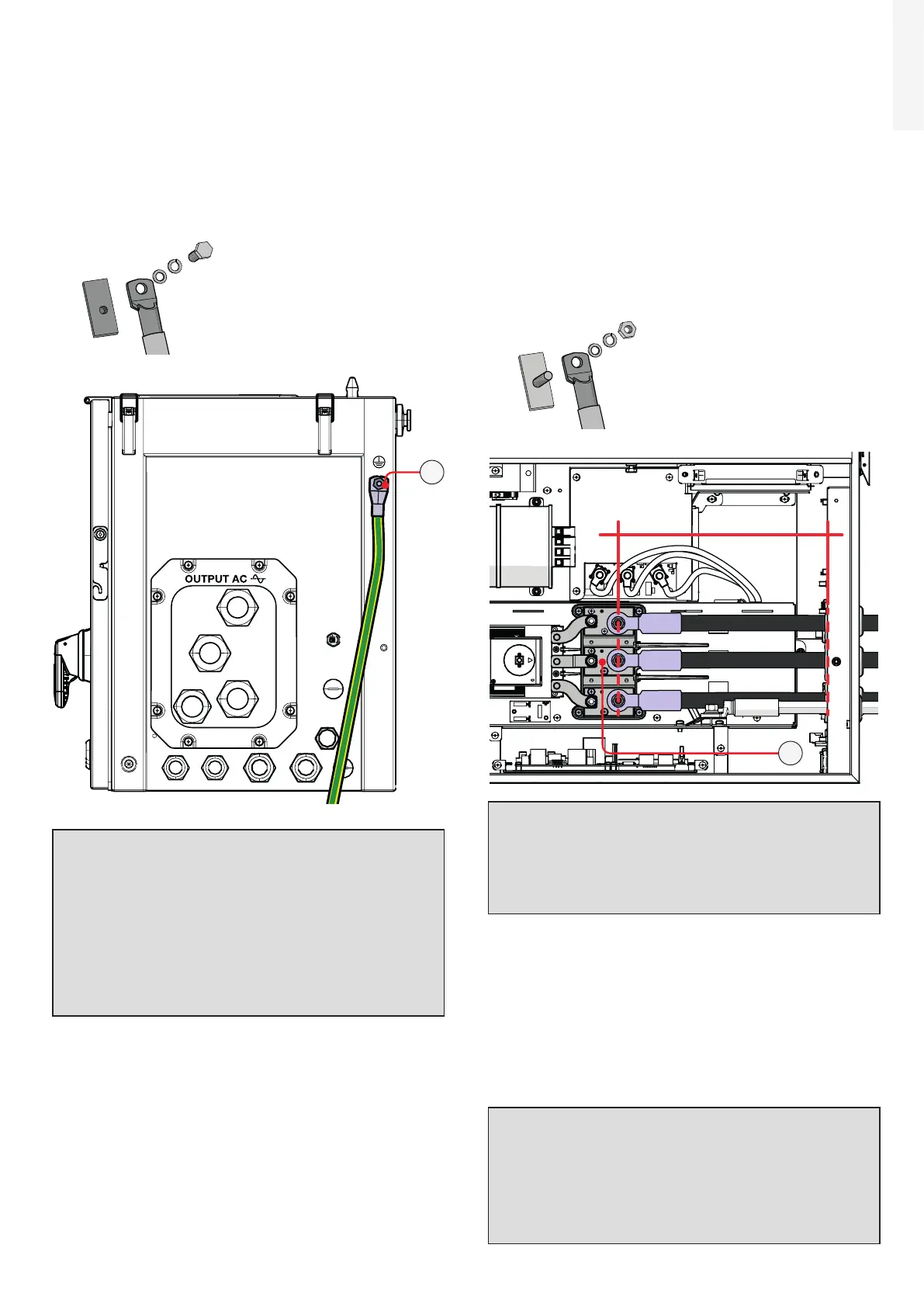

External ground connection

• Fix the protective earth cable lug to the protection

earth connection point (ext.) (10) (this is the same

thread for handles) using the washers and M8

bolt provided in the wiring box installation kit, as

shown in the following diagram:

1 = cable lug

2 = flat washer

3 = spring washer

4 = M8 bolt

1

2

3

4

10

ATTENTION – A The cable lug must be

installed with a tightening torque of 15.2 Nm.

ATTENTION – A Before connecting the

inverter to AC or DC sources use a suitable

multimeter to test the conductivity of the

earth connections between the protection

earth connection point (ext.) (10) and a

handles thread (04) on the housing of power

module.

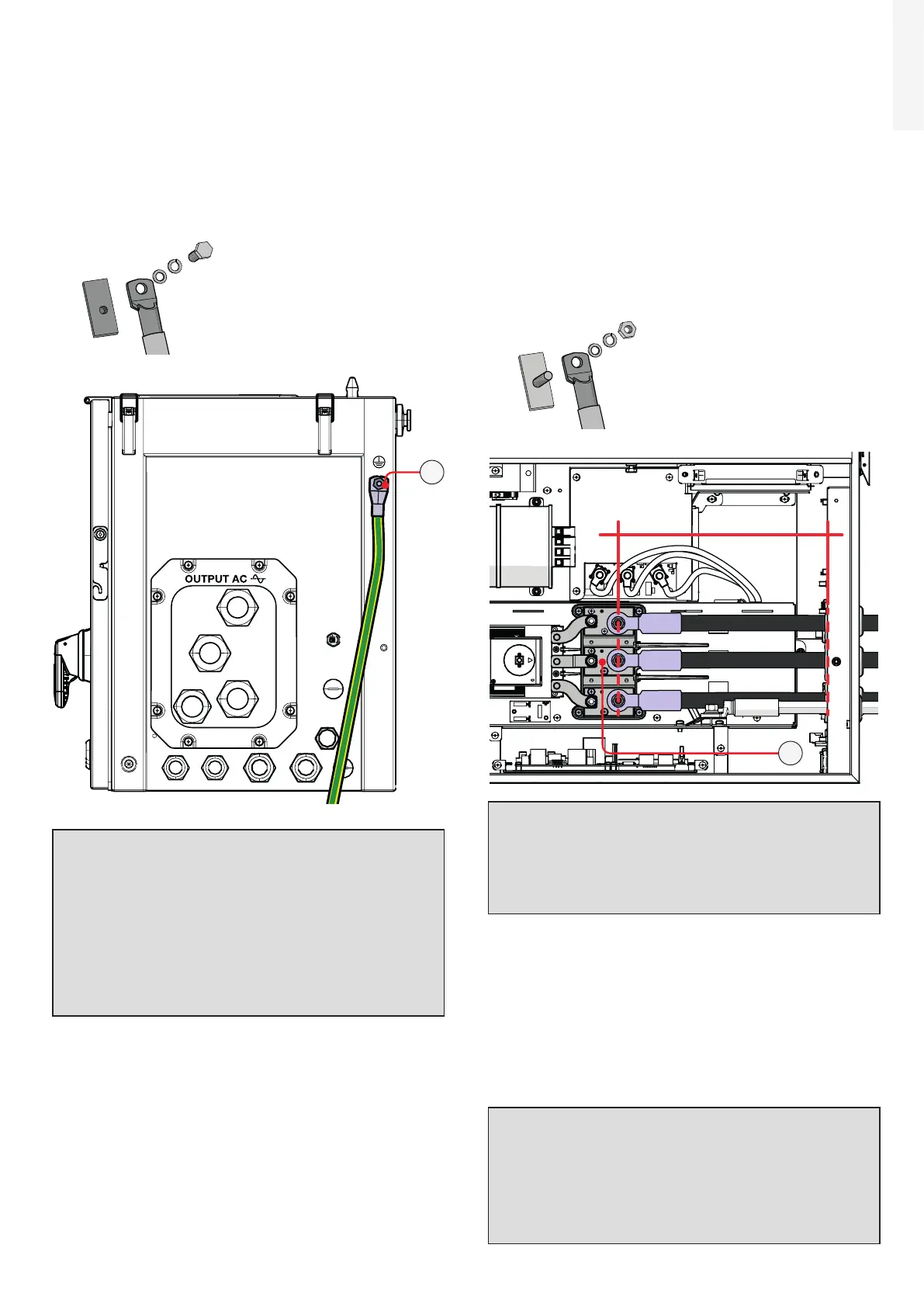

AC line connection

• Pass the AC cables through the cable glands (11)

on the AC panel. The lenght of phase cables on

the internal side of wiring box need to be about

300 mm (cable lug included).

• Fix the R, S and T cable lugs to the AC

connection busbars (27), paying attention to the

correspondence of the phases with the labels,

using the washers and the M10 nuts pre-installed

on the busbar as shown in the following diagram:

1 = cable lug

2 = flat washer

3 = spring washer

4 = M10 nut

1

2

3

4

RST

R

300mm

S

T

27

ATTENTION – A In case of a wrong phase

sequence the inverter will not connect to the

grid and it will provide an error state.

ATTENTION – A The cable lugs must be

installed with a tightening torque of 25Nm.

• Re-install the AC protective shield (23) by using

the M5 screw and the M5 nut previously removed

with a tightening torque of 3 Nm.

• Check the tightness of the AC cable glands (11)

(5 Nm for single core AC cable gland M40 / 18 Nm

for multi core AC cable gland M63) and, if used,

protective earth cable gland (12) (5 Nm for PE

cable gland M32) at the end of the installation.

ATTENTION – A In case of the AC cable

glands (11) was accidentally removed during

the cable routing phase, it will needed to

assure the correct tightness of the lock nut

of the cable gland to the inverter chassis with

a tightening torque of 8.0 Nm (for each cable

gland).

Loading...

Loading...