Action

Jog the robot so the torch is about 150 mm above the plate and modify the last MoveJ.11

Move the program pointer to the beginning of the routine, and start execution. The

robot should go from point to point with the torch TCP, stopping at each point so that

the position can be checked. If any positions need to be changed, change them now.

12

Move the program pointer to the procedure SearchSample.13

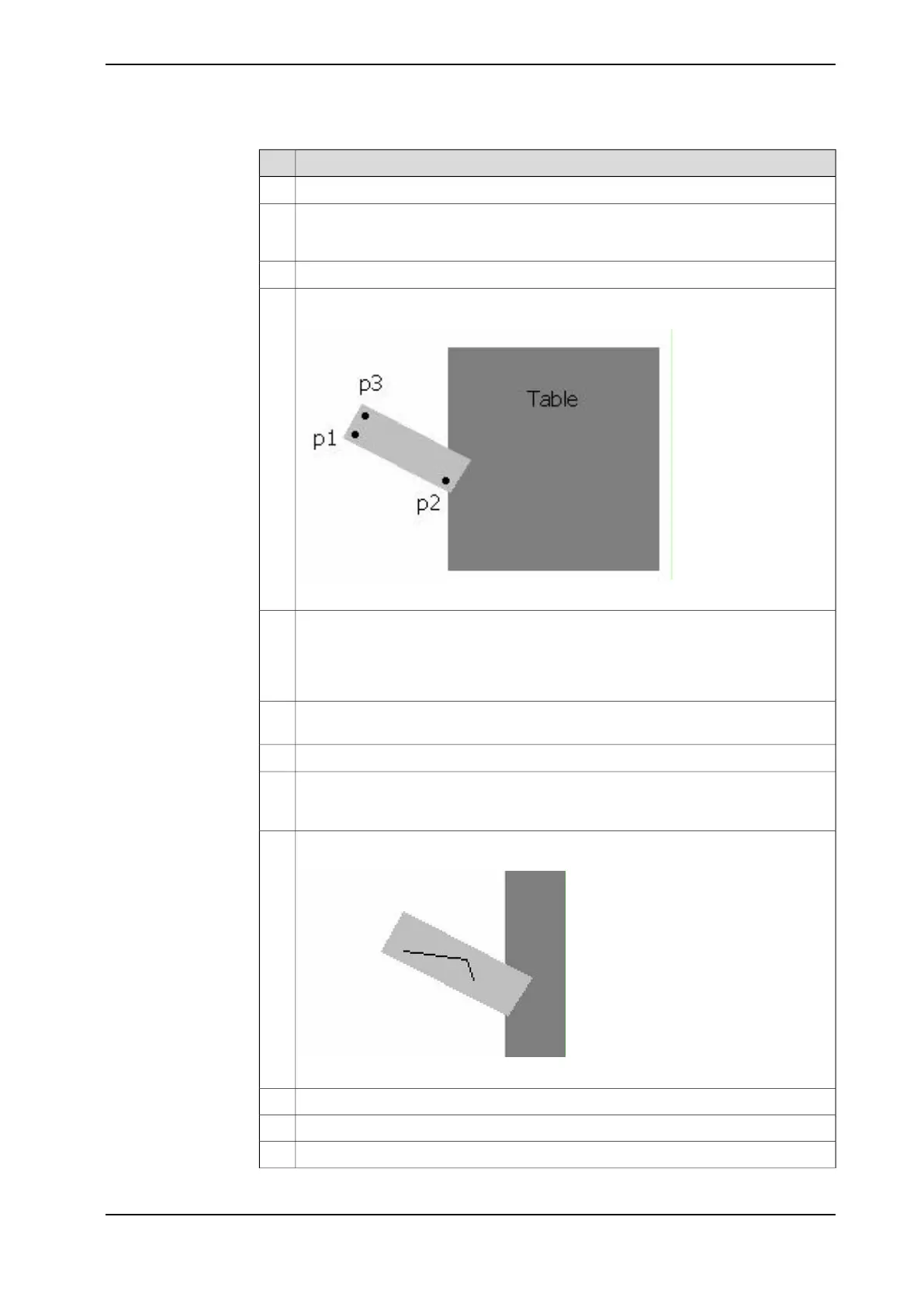

Jog the robot so that the torch TCP is above the plate and off the corner where p1

is. Modify the first MoveJ.

xx1400001514

14

Jog the robot down so that the torch gas cup is in a position to search the edge of

the plate. See Reference sketch on page 63, and modify the points the first

Search_1D. The search direction is indicated in the sketch for the displacement

frame pe1a (the first search result). Remember that the search direction should be

perpendicular to the edge of the part.

15

Modify all the rest of the moves and searches as shown in Reference sketch on

page 63.

16

Test run the SearchSample procedure.17

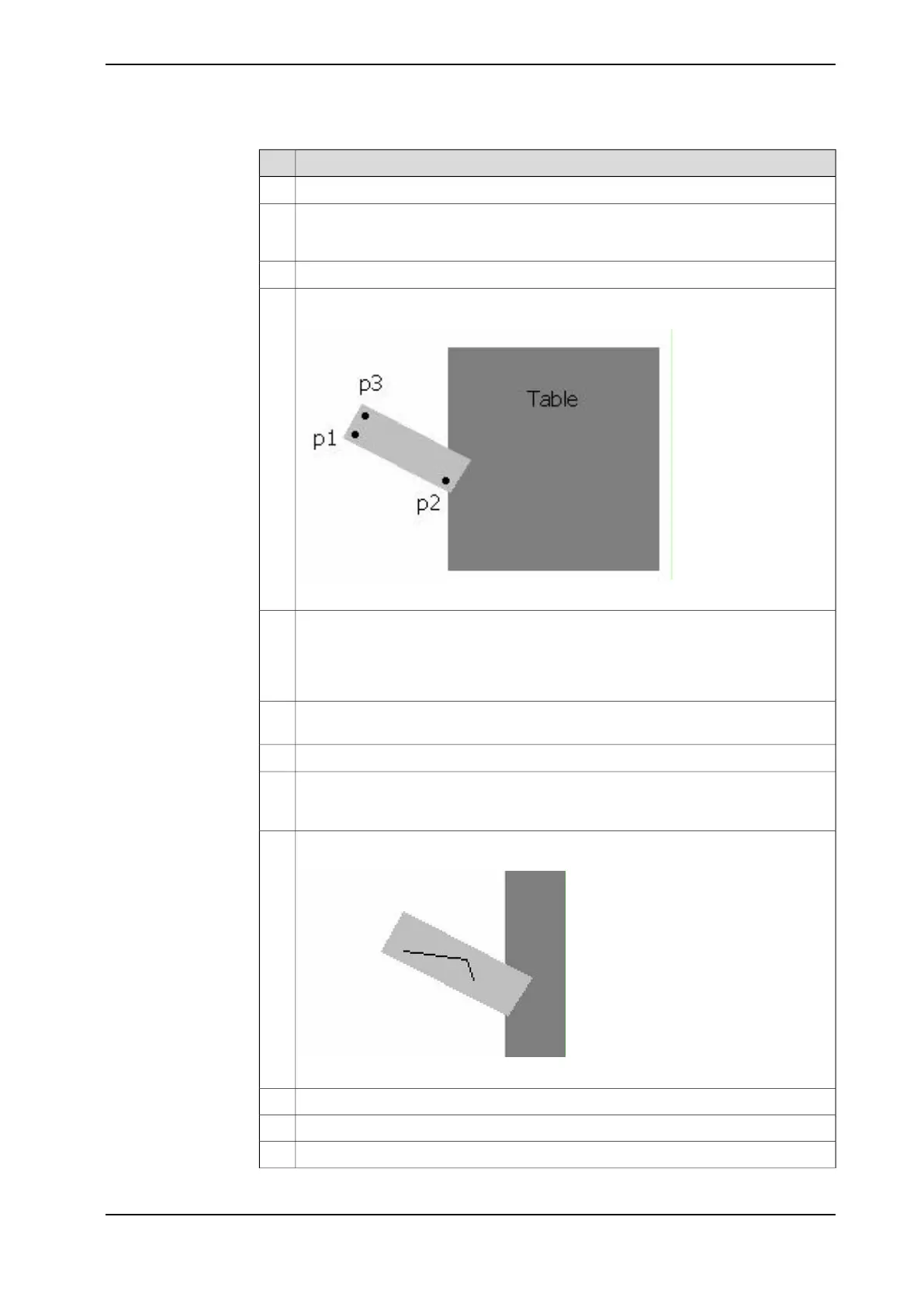

Move the program pointer to the routine called WeldSample. WeldSample does not

have any ArcL instructions so RobotWare Arc does not need to be present to load

this module. It has only MoveL instructions with slow speeds to simulate welding.

18

Draw a simulated weld on the surface of the plate using a straight edge and marker.

WeldSample has only two segments. Add more if desired.

xx1400001515

19

Modify the first point to be above the plate at least 100 mm.20

Modify the second point to be the start of the simulated weld.21

Modify the third and fourth points to be the middle and end of the weld.22

Continues on next page

Application manual - SmarTac 65

3HAC024845-001 Revision: A

© Copyright 2004-2016 ABB. All rights reserved.

4 User's guide

4.7.3 Exercise 5: object frame manipulation

Continued

Loading...

Loading...