American Beer Equipment 2001 SW 6

th

St.

Lincoln, NE 68522

6

4. Canning Procedures

a. Filling

i. Please follow the attached “Beer Pre-Start” and “Operator Setup Sheet” before canning each

time (page 51).

ii. A summarized version of the above is as follows. Connect:

a. ½” main air line at filler on backside

b. ¼” C02 line at filler on backside

c. 1-½” sanitary line (Beer)

iii. When you are ready to start canning, go to “Input & Outputs” on the HMI screen (Figure 1)

a. Click “Enable Testing” (Must always be depressed first for any action to take

place)

b. Cycle “Can Push” and “Push to Seam” to make sure the cylinders are running

smoothly. If they are not, see if beer has dried on the shafts. Hot water and FDA

approved silicon spray will produce a smooth cylinder operation.

c. Use the CIP button to cycle the Nozzles until beer exits, and there is minimal

foam

d. Make sure sanitizer or other chemicals have exited the system

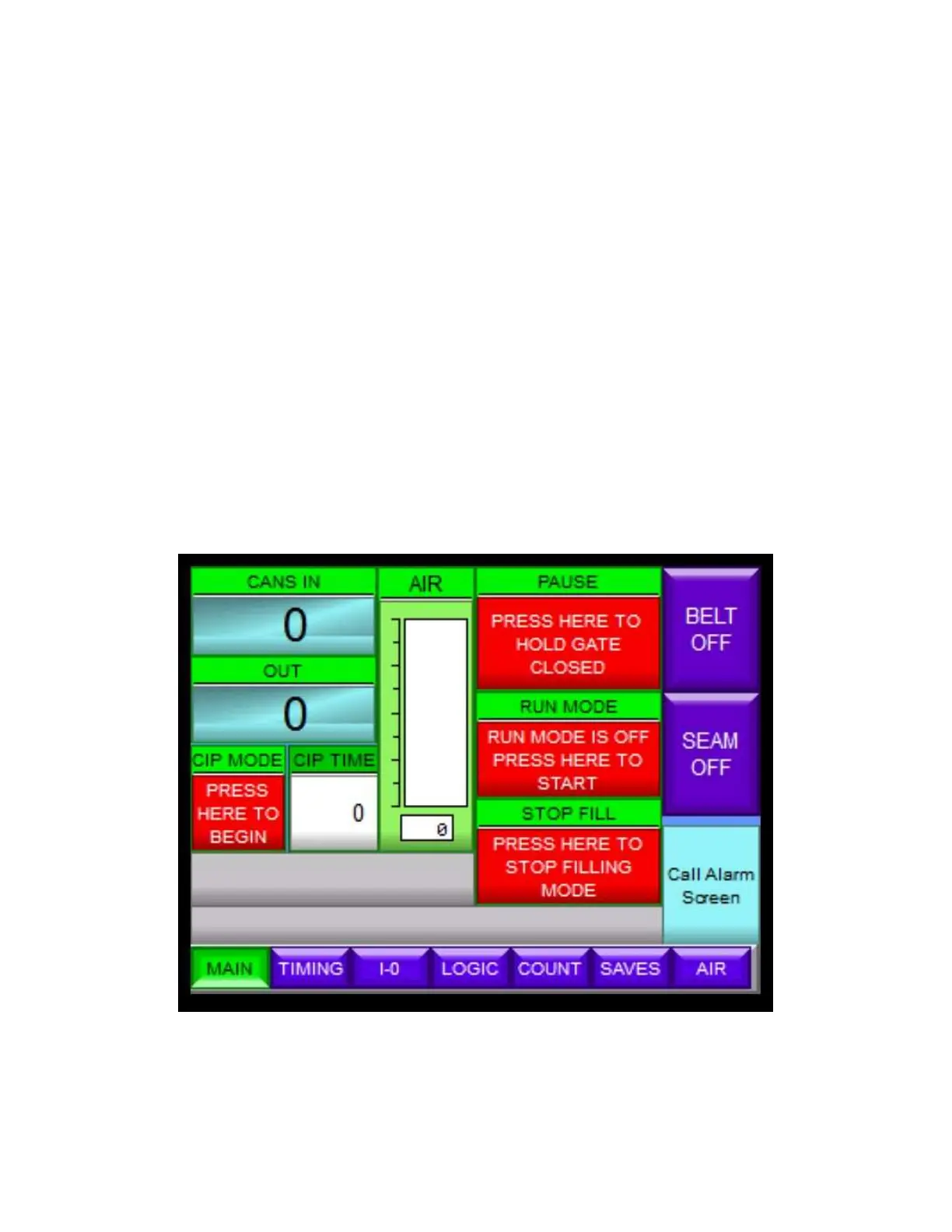

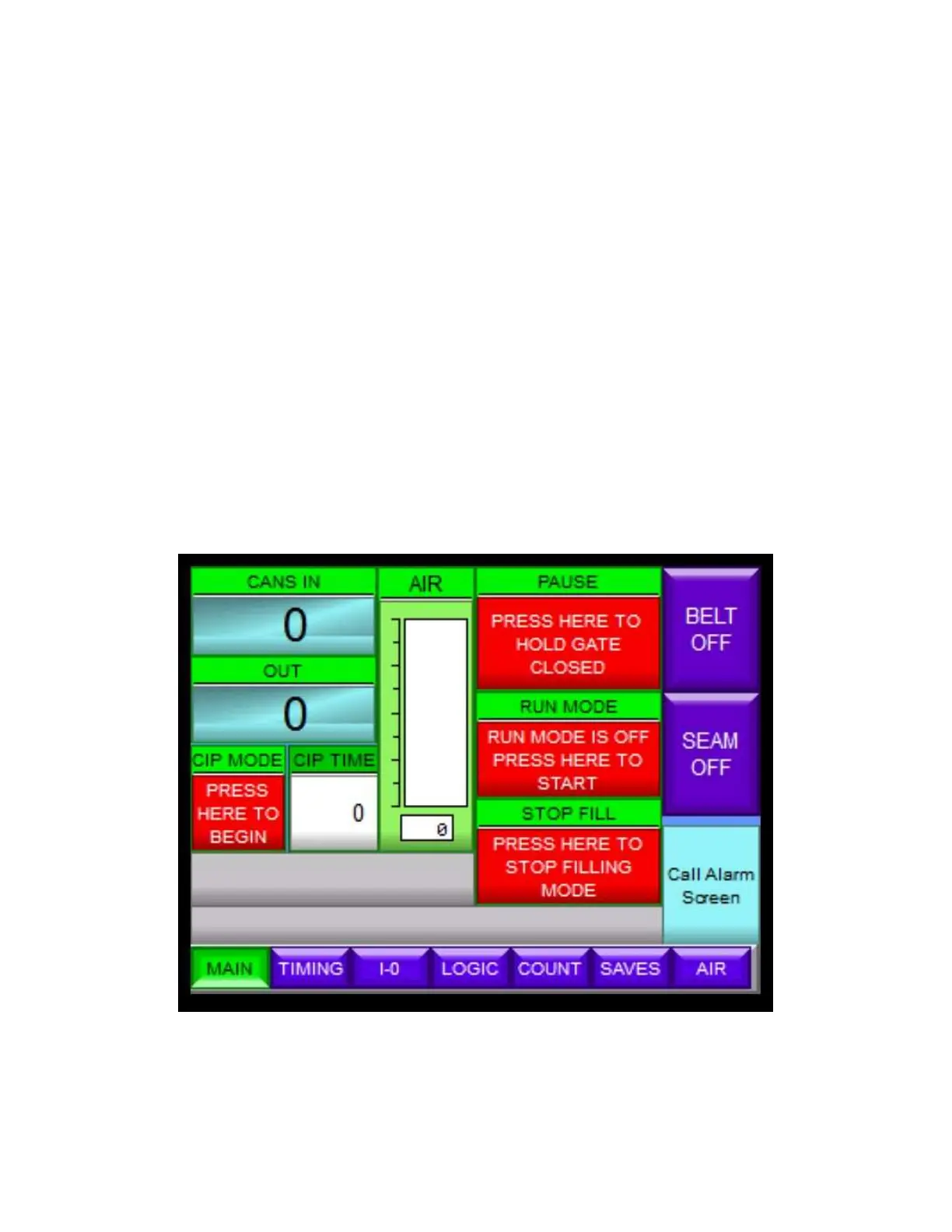

iv. Next, go to the “Main” Screen

Figure 1. Main Screen

Loading...

Loading...