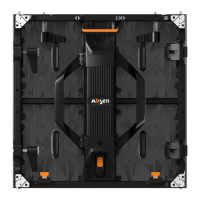

The Absen PL Lite Series is a display product specifically engineered for stage rental applications, including large concerts, shows, auto shows, and business activities. It serves as a versatile medium for video broadcast and information dissemination. The series is designed with a modern die-casting aluminum structure, ensuring excellent flatness, high-quality cabinet and module finish, and robust structural strength.

Usage Features

The PL Lite Series offers a comprehensive range of pixel pitches, including 2.5mm, 2.9mm, 3.9mm, and 4.8mm, with outdoor versions available for P3.9 and P4.8. This variety allows for flexible deployment in different environments and viewing distances. The series also includes curve and cube versions (PL2.5 Lite/PL2.9 Lite/PL3.9 Lite/PL3.9W Lite only), providing diverse creative splicing solutions for unique stage designs.

A key feature of the PL Lite Series is its high refresh rate of 3840Hz, which delivers an outstanding effect on camera, significantly enhancing customer satisfaction, especially in broadcast environments. The PL3.9W Lite and PL4.8W Lite models boast a high brightness of 4500nit, coupled with ultra-high contrast and distinct color layers, ensuring excellent visual performance even in outdoor settings.

The curved version of the PL Lite Series offers exceptional flexibility, supporting any increment of curve from -7.5 degrees convex to +10 degrees concave. This allows users unlimited design and operational freedom to create dynamic and immersive visual experiences.

Installation of the PL Lite Series is streamlined by an advanced locking system equipped with a safety mechanism, enabling efficient one-person installation. The product supports various installation methods, including rigging and stacking. For rigging, single, double, and 90-degree hanging bars are available. The hanging bars can support a maximum of 20 500x500mm panels or 10 500x1000mm panels. The installation process involves fixing the hanging bar to a truss, aligning the cabinet's safe lock with the mounting hole on the hanging beam, pressing the locking plate, inserting the safe lock, and tightening it from left to right. For stacking installations, cabinets are equipped with a curved lock that supports radian connections from -7.5 to +10 degrees.

The product's cabling system is designed for reliability and ease of use. Network and power cables are connected via aviation connectors. Users are advised to ensure proper power and signal circuit connections, checking for short circuits with a multimeter before powering up. The system supports various distribution box specifications (15KW to 180KW) and power supply models (MEGMEET MCP200WS-4.5A and MSP260-4.5), accommodating different input voltages (100-240V/AC). The number of cabinets that can be carried by wires varies based on cabinet size and input voltage, with detailed tables provided for guidance. It is crucial to calculate the resolution based on each box pixel and connect the signal line according to the sending card's load range, ensuring no more than 655360 pixels are loaded on each network port.

Maintenance Features

The PL Lite Series is designed with modularity in mind, facilitating fast and efficient maintenance of modules and power boxes. Indoor 500x500 cabinets can be customized to support both HUB and PCB front maintenance, further enhancing serviceability.

Module Maintenance:

Modules can be maintained from either the front or the rear.

- Front Maintenance: A vacuum maintenance tool is used to attach to the module. By pressing the tool's switch for 5 seconds and pulling vertically, the module can be detached from the panel. This allows for easy removal of a faulty module and replacement with a new one.

- Rear Maintenance: For rear maintenance, the module handle is pushed forward to release it. The faulty module can then be removed and replaced.

Power Box Maintenance:

- 500x500mm Cabinet: The power box knob is switched to the unlock position, allowing the yellow power box to be buckled up and removed. After removing the fixed screw of the power supply, a new power box can be installed.

- Other Cabinets: For other cabinet types, loose screws on the power box are unscrewed to remove it for maintenance.

- Important Safety Note: It is essential to cut off the power supply to the cabinets during power box maintenance to prevent electric shock.

Receiving Card and HUB Board Maintenance:

The A5S receiving card connects to the HUB board via a card slot, and the HUB board, in turn, connects to the module, power supply, and data cable, facilitating power and data transmission. All series products support rear maintenance for the receiving card and HUB board. Indoor 500x500 cabinets can also be customized for front maintenance of these components.

- Receiving Card Rear Maintenance: This involves removing the screws of the receiving card, unplugging it, and replacing it with a new one. Care must be taken to align the new receiving card's direction with the arrow direction on the HUB board. Finally, the fixing screws are reinstalled.

- HUB Board Rear Maintenance: Similar to receiving card maintenance, this involves removing the fixing screws to access and replace the HUB board.

- Receiving Card Front Maintenance (Indoor 500x500 cabinets, customizable): This more involved process requires removing the power box and module from the cabinet. Then, screws from the front of the cabinet are removed. The HUB board and receiving card can then be accessed and replaced from the back side. Proper alignment of the receiving card with the HUB board's arrow direction is crucial. After replacement, the HUB board, screws, power box, and module are reinstalled.

Flight Cases:

To protect LED panels from SMD damage during transport, flight cases are provided. These cases are optimized for vehicle transport, offering a low-cost solution, and are fully stackable to save space. The PL Lite series offers 6-in-1 flight cases for 500x500 cabinets and 4-in-1 cases for 500x1000 cabinets.

Troubleshooting:

The manual provides a comprehensive troubleshooting guide for common faults, including:

- Some modules are black: Solutions range from checking power plug insertion, power cable integrity, switch power supply output, and flat cable functionality to replacing the flat cable, module, receiving card, or sending an rcfg file.

- The whole screen is black: This can be resolved by checking if the screen power is on, DVI/HDMI cable connection, main data cable insertion, sending card power and indicator, or by replacing the sending card, checking computer video output, updating video card driver, or replacing the computer.

- Screen shows scrambled image: Solutions include checking the power plug of the receiving card and power cable integrity.

- Chromatic aberration between modules: This can be addressed by checking the module power plug, replacing the flat cable, power supply, module, or receiving card.

- All panels display the same content: This points to issues with screen connection settings in the software or incorrect data port usage.

- No control system detected: Troubleshooting involves checking the USB cable, computer USB port, updating the USB driver, or replacing the USB cable or sending card.

- No multi-function card detected: Solutions include checking if the distribution box is in automatic state, if the multi-function card is powered, replacing its power supply, checking main data cable insertion, sending card data port, re-adding or replacing the multi-function card, or replacing the sending card.

- No full screen display: This requires checking playback window settings, output resolution of the video processor, and output window of the video processor.