© ADB Airfield Solutions All Rights Reserved 15

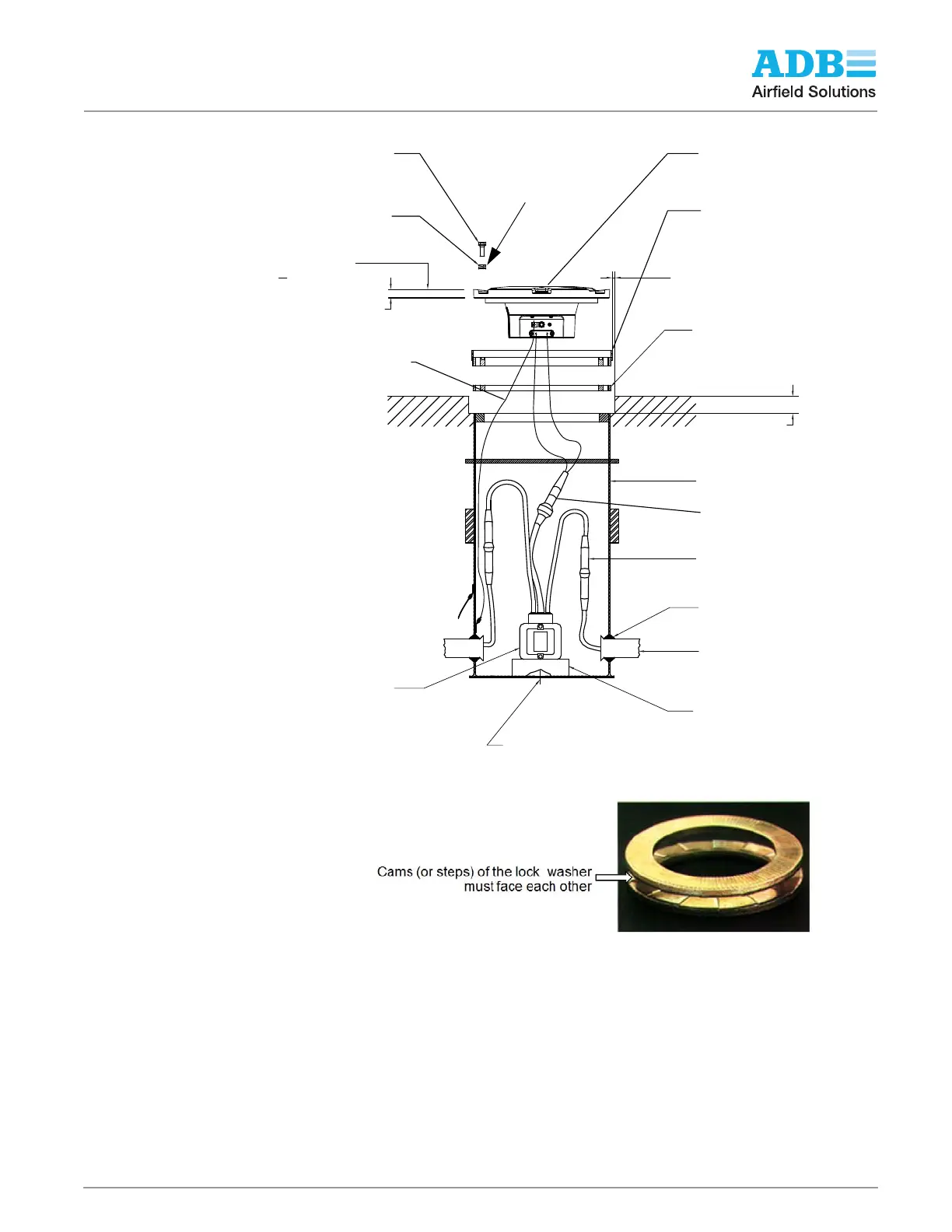

Figure 5: Diagram of the Fixture Installed in a 1-Piece Base Can

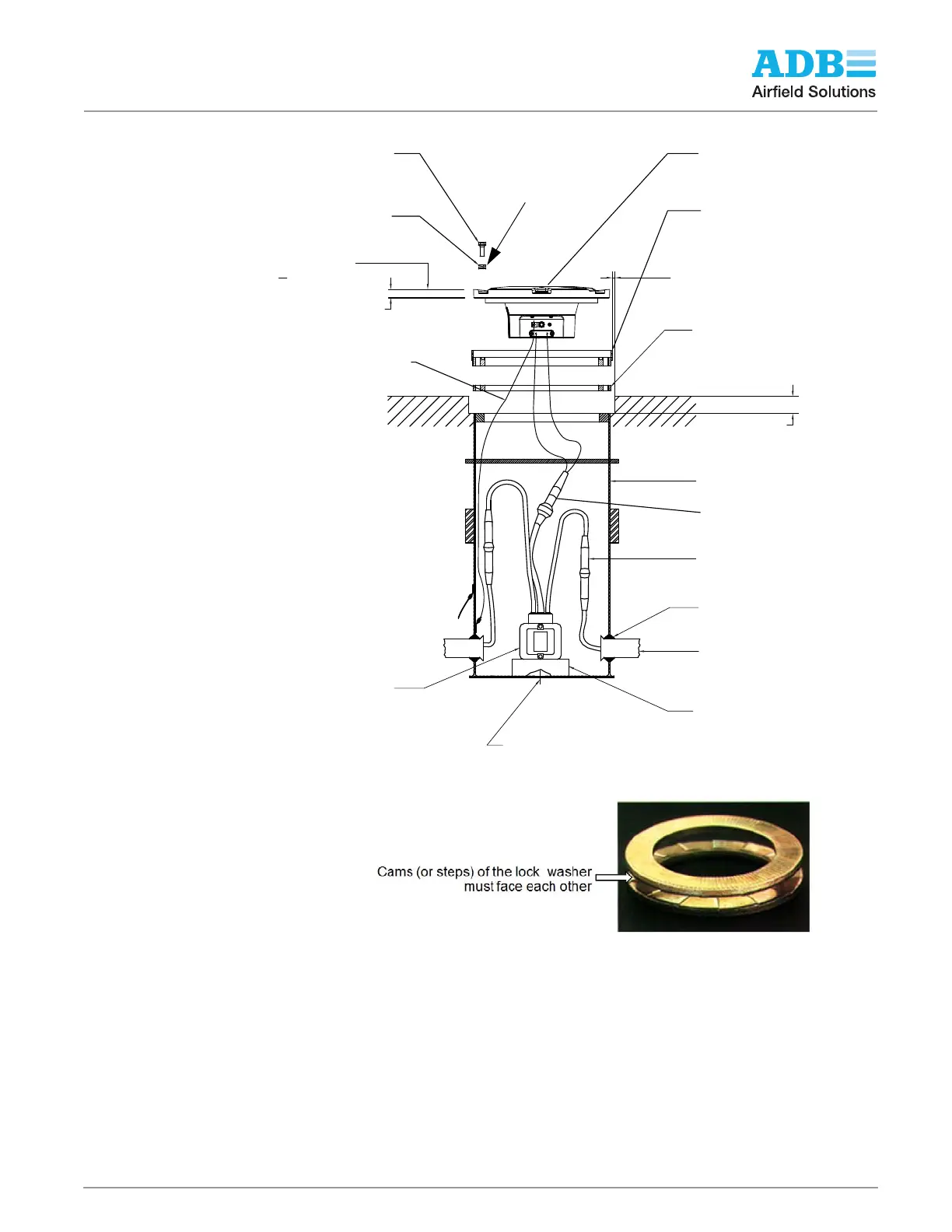

NOTE:

The cams (or steps) of each half of the lock washer must face each other.

NOTE: Per FAA AC 150/5340-30, Chapter 10, and FAA Engineering Brief No 83, it is

extremely important that other types of washers, such as split washers, must not be used.

Failure to use properly installed anti-vibration lock washers will cause mounting bolts to

become loose.

1-1/2" (TYP.)

1/4" WIDE X 1-1/2" DEEP GROOVE (TYP.)

L868B FLANGE RING 12.25" O.D.

3/4" THICK, 5402/12Y

WITH O-RING GASKET (TYP.)

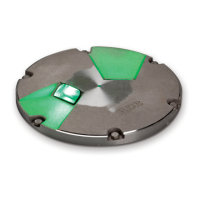

SEMI-FLUSH

LIGHT FIXTURE

TYPE L-85X (TYP.)

NORDLOCK NL 3/8 2 PIECE LOCKWASHER OR EQUAL

3/8-16 STAINLESS STEEL BOLT

(TYP. OF 6)

0.75"

GROUND WIRE

6AWG

L868B LIGHT BASE

L-823 PRIMARY CONNECTOR

(TYP.) (HEATSHRINK OPTIONAL)

GROMMET

TRANSFORMER SUPPORT

(TYP.)

ISOLATION TRANSFORMER

SIZE AS REQUIRED

L868B SPACER RING(S)

2" PVC CONDUIT W/BELL END

3/4" DRAIN HOLE (CENTERED)

FIXTURE TOP EDGE TO BE

+0/-

1

16 " BELOW GRADE

L-823 SECONDARY CONNECTOR

In order to maintain +0/- 1/16” below grade, per FAA installation tolerance,

a maximum of 3 spacers may be used.

See notes

below

Torgue according to: “Installation on

L-868 Base” on page 16

Loading...

Loading...