14

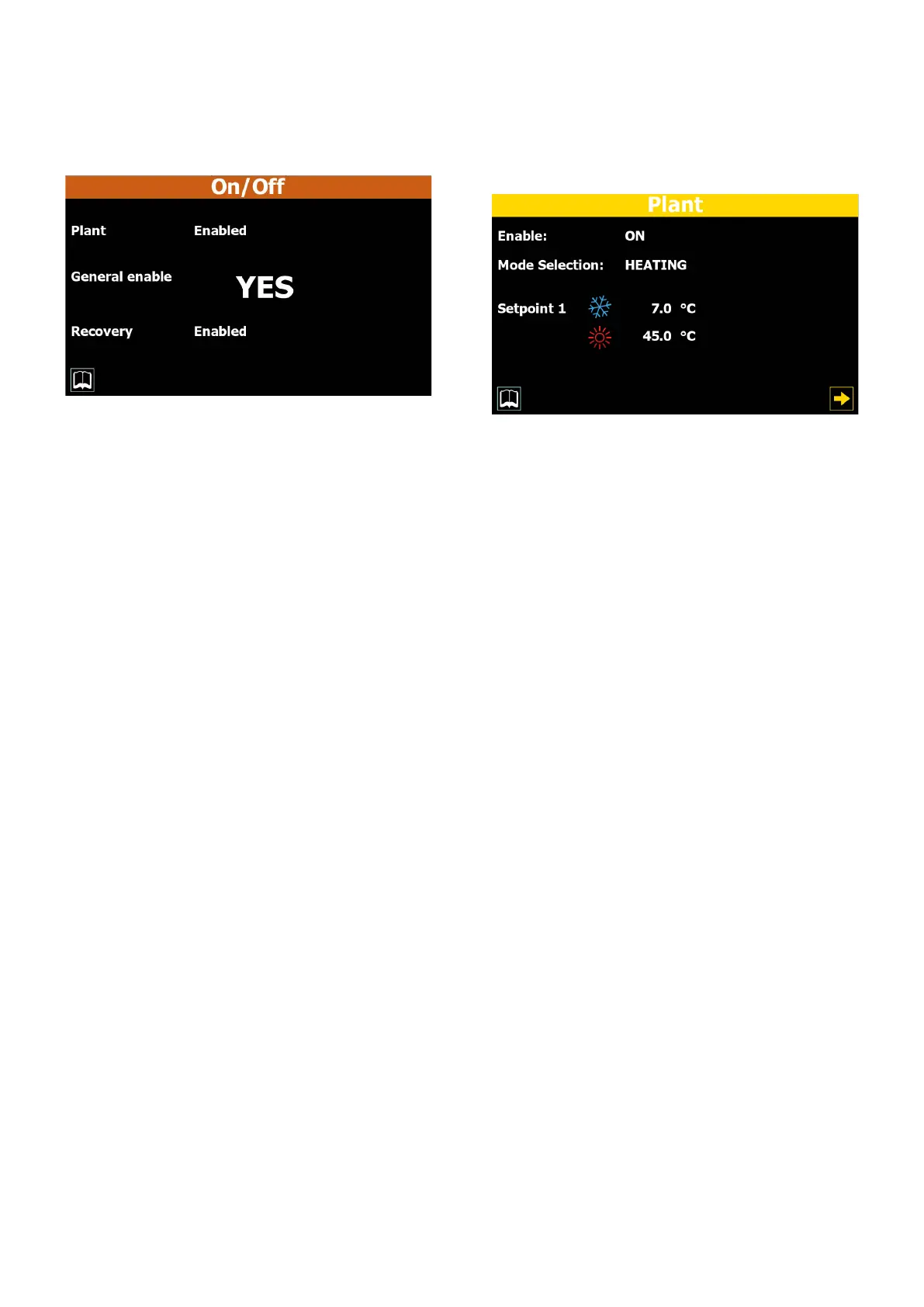

5 ON/OFF MENU

The ON/OFF menu is used to switch the unit on or o. It also provides further infor-

mation about the current status of the machine.

5.1 SWITCHING THE UNIT ON/OFF

— System status. This status may be:

No info = Unit operating;

General OFF via key = Unit switched o via the interface;

Unit OFF via alarm = Unit switched o due to an alarm condition;

OFF via supervisor = Unit switched o via BMS;

OFF via time bands = Unit switched o due to the current time band setting;

OFF via digital input = Unit switched o due to a digital input signal (ID17);

Antifreeze = Unit operating in antifreeze mode;

OFF via Master = Unit switched o via the MASTER unit;

Outside operating limits = Unit switched o because it was working outside its

operating limits (for more information about the unit operating limits, refer to the

technical manual of the unit);

Boiler replacement = Unit switched o because replaced by the boiler for hot water

production;

— Indicates the current value selected (YES = Unit ON; NO = Unit OFF)

— Status of the recovery circuit (if installed). This status may be:

No info = Unit operating;

General OFF via key = Unit switched o via the interface;

Unit OFF via alarm = Unit switched o due to an alarm condition;

OFF via supervisor = Unit switched o via BMS;

OFF via time bands = Unit switched o due to the current time band setting;

OFF via digital input = Unit switched o due to a digital input signal (ID17);

Antifreeze = Unit operating in antifreeze mode;

OFF via Master = Unit switched o via the MASTER unit;

Outside operating limits = Unit switched o because it was working outside its

operating limits (for more information about the unit operating limits, refer to the

technical manual of the unit);

Boiler replacement = Unit switched o because replaced by the boiler for hot water

production;

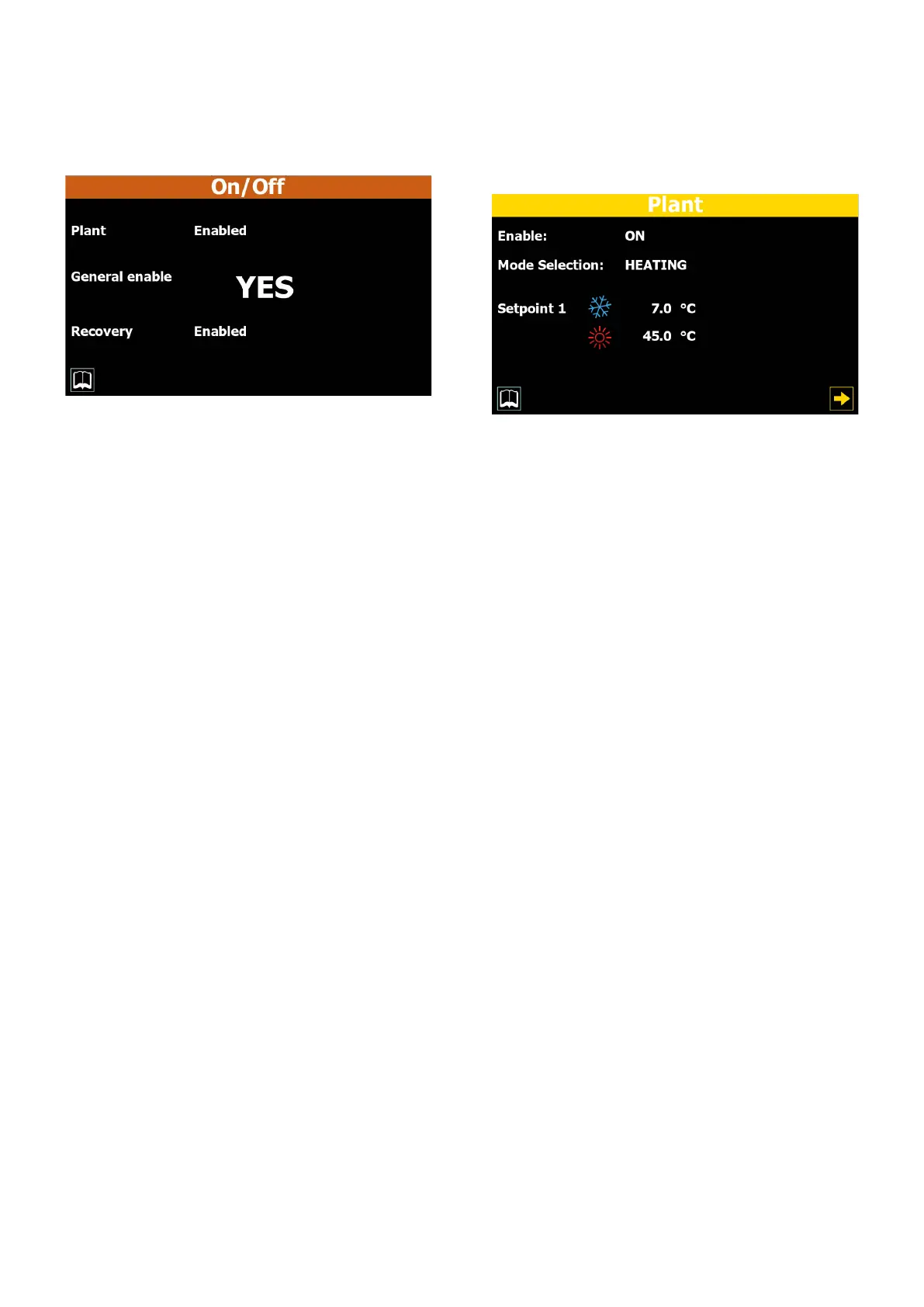

6 SYSTEM MENU

The SYSTEM menu is used to set the operating mode and the set-point values for

the various modes.

6.1 SETTING THE OPERATING MODE AND THE MAIN SET

POINTS

1. Enable:

Indicates which type of adjustment is currently active on the unit. This may be:

— OFF = The unit is not producing water;

— ON = Unit adjustment is based on the main probe, according to the system set-

point;

— ON with Set 2 = Unit adjustment is based on the main probe, according to set-

point 2 (which can also be activated via digital input ID10, or the time bands);

— Time bands = Unit adjustment is based on the timed program currently ac-

tive (for more information about the timed programs, refer to the "Time band

menu");

2. Mode selection:

Indicates which operating mode is currently active on the unit. This may be as fol-

lows (the choice is only available for heat pump units):

— Cooling = The unit produces cold water on the basis of the current operating

set-point;

— Heating = The unit produces hot water on the basis of the current operating

set-point;

— Via ext. temp. = The unit chooses whether to activate cooling mode or heating

mode on the basis of the outside air temperature;

— Via dig. input = The unit chooses whether to activate cooling mode or heating

mode (Open = cooling; Closed = heating) on the basis of the status of digital

input ID16;

— Via superv. = The mode is set by the supervisor (BMS);

— Via calendar = The mode is set according to the value shown in the window (of

this menu) for the dates when cooling or heating mode should be activated;

3. Setpoint 1:

Indicates the current value of the main cooling set-point;

Indicates the current value of the main heating set-point (on heat pump only);

Loading...

Loading...