10 22.11 5806712_07

3 PREINSTALLATION

RECEIVING THE PRODUCT

Inspection upon receipt

To prevent damage during transport, the units are completely wrapped in packag-

ing and protected by plastic elements.

The machine is also wrapped in packaging. We recommend keeping this protection

during all transport and lifting operations and not remove the plastic elements until

commissioning.

There is a document envelope located inside the access panel to the electrical parts

that contains the following material:

— Instruction manual for the installer and the technical service, with the declara-

tion of conformity on the rst pages

— Unit user manual

— Wiring diagrams

The instruction manual is an integral part of the unit and therefore it must be re-

covered, read and stored carefully. If lost, a copy can be found in the support area

online at www.aermec.com.

Upon receipt:

— Check that the exterior has not been damaged in any way;

— Check that the lifting and transport devices are appropriate to the type of

equipment and compliant with the transport and handling instructions at-

tached to this manual;

— Check that the accessories required for on-site installation have been delivered

and are operational;

— Check that the equipment supplied corresponds to the order and delivery note.

ATTENTION! If the product is damaged, send a registered letter with

the details of the problem to the shipping company within 48 work-

ing hours from delivery.

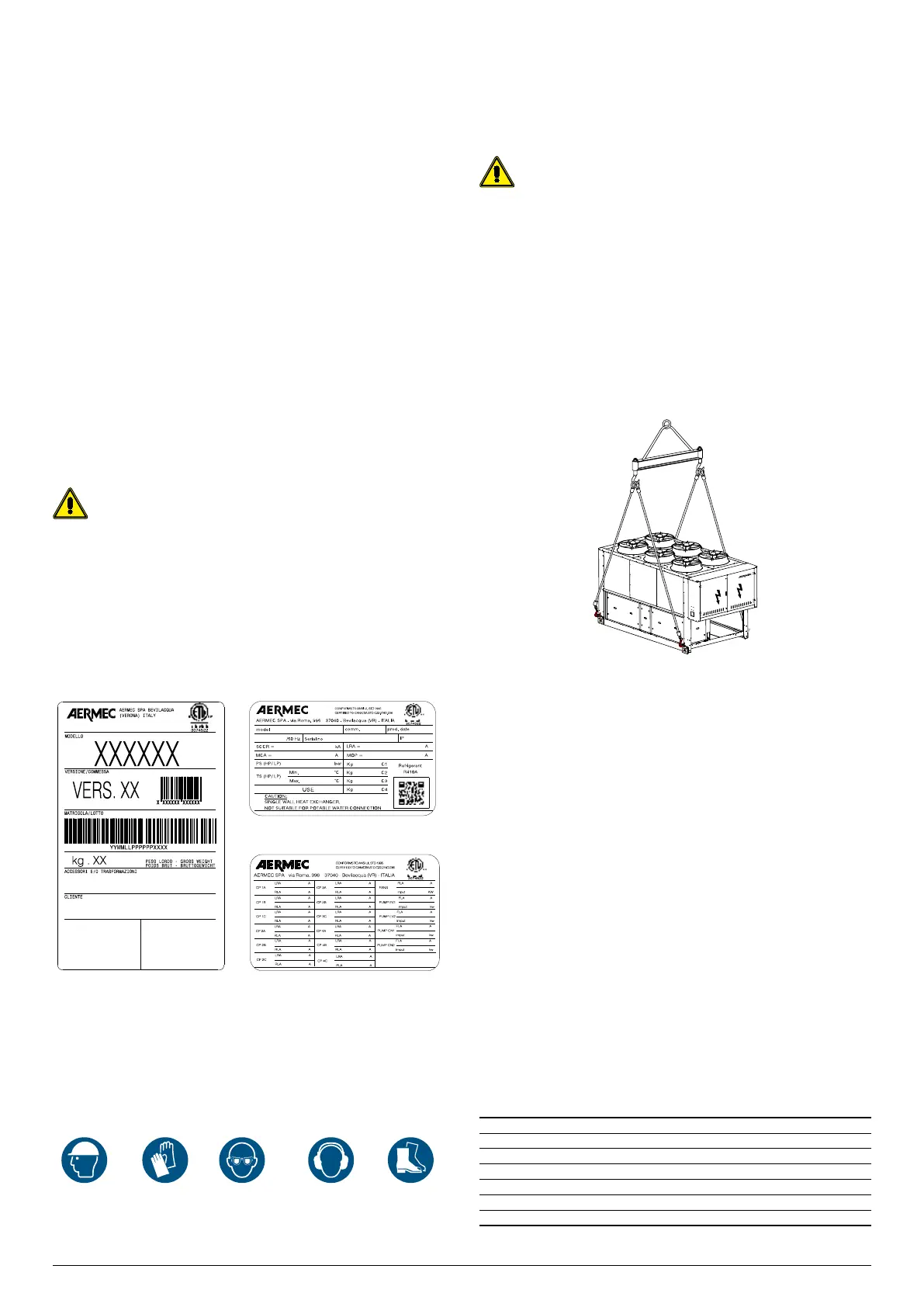

Product identication

Aermec products are identiable by the packaging label that shows the product

identication data, and by the rating plate that shows the performance and iden-

tication technical data of the unit in your possession.

When the unit is positioned, make sure that the rating plate is well visible as the

information provided on it is essential for correct maintenance.

Packaging label Technical plate

Compressor data plate

PACKAGING HANDLING AND REMOVAL

Before carrying out the packaging removal or transport operations, put on personal

protective equipment and use devices and instruments suitable for the dimensions

and weigh of the equipment.

All handling operations must be performed by qualied personnel in strict compli-

ance with all the applicable safety procedures.

The handling operations must be carried out carefully to prevent damage. The unit

may only be handled in a horizontal position and only from its base.

It is prohibited to dispose of the packaging material in the environ-

ment or leave it within reach of children: as it may be a potential source

of danger. Therefore it must be disposed of according to what is dened

by current laws.

The unit may be handled in two ways, using:

— A hoist or a crane;

— A forklift.

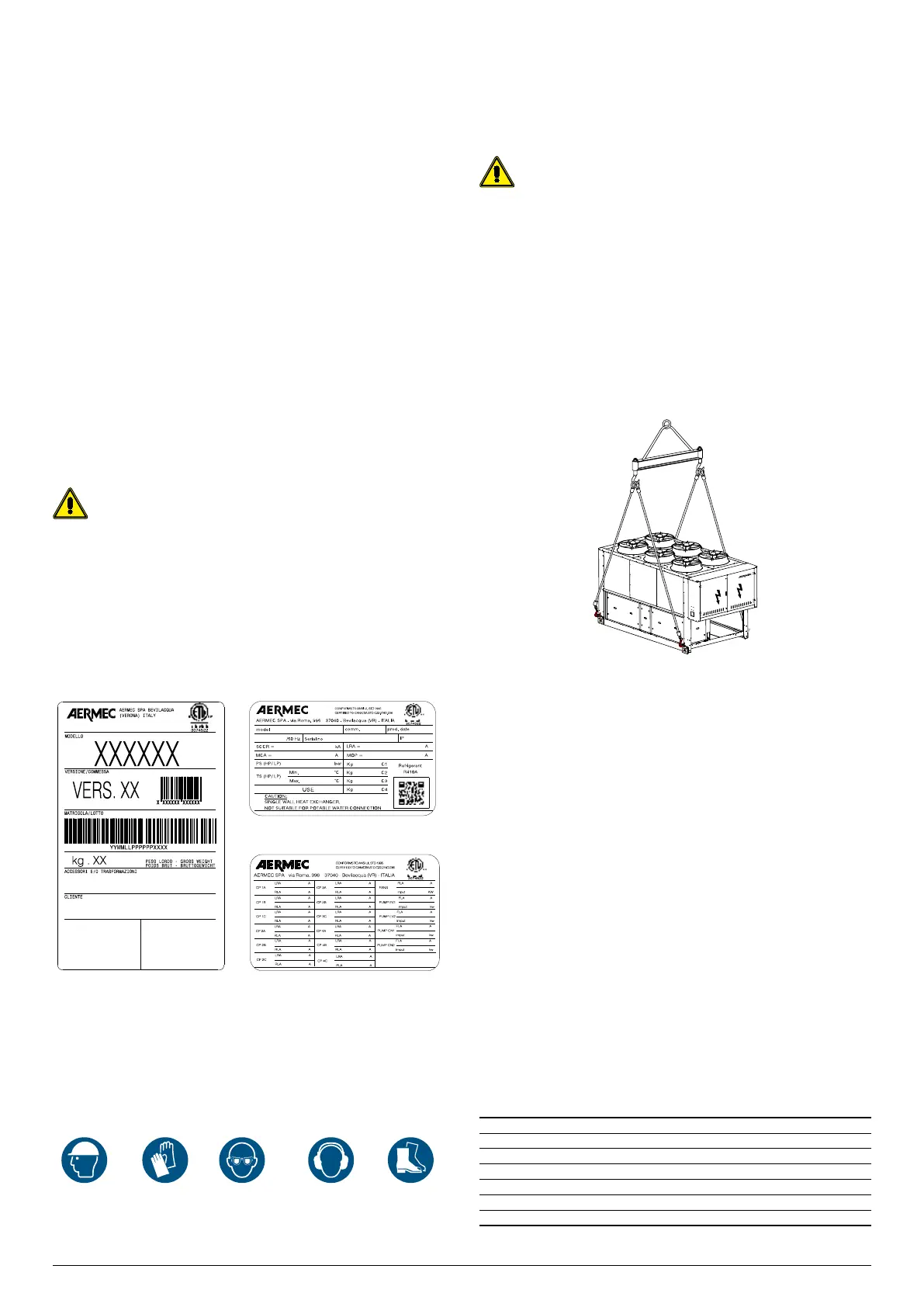

LIFTING WITH A HOIST OR CRANE

Before lifting the unit, place protections between the belts (or ropes and chains)

and the framework to prevent damage to the structure.

In case of handling with hoist or crane, the unit is supplied with eye-

bolts; they must be lifted using suitable straps hooked to all the in-

stalled eyebolts.

The following is required:

— Follow all safety regulations and standards;

— Before lifting, check the specic weight on the technical plate;

— Wear safety glasses, work gloves and safety shoes;

— Pay the utmost attention to heavy and bulky equipment during lifting and han-

dling, and when placing it on the ground;

— All panels must be tightly xed before moving the unit;

— Use all, and only, the lifting points indicated;

— Use ropes in compliance with Standards and of equal length;

— Use a spacer in accordance with the sling (not included) see drawing;

— Handle the unit with care and without sudden movements;

— Do not stand under the unit during lifting;

STORAGE

It is possible that the units may not be immediately installed upon receipt. If they

are stored for a medium-long period of time, the following procedures are recom-

mended:

— The units cannot be stacked;

— Check for any damage

— Make sure there is no water inside the hydraulic systems;

— Do not remove the protections from the heat exchanger;

— Do not remove the plastic protective lms;

— Make sure that the electrical panels are closed;

— Before using the equipment, put all the supplied items in a dry and clean loca-

tion so that they can be used in the future.

The minimum and maximum unit storage temperature depends on the

type of refrigerant used, see the table. Above this limit, there is a risk of

refrigerant leaks through the pressure relief valves.

Maximum storage temperature

Refrigerant Type Class Min temp. (°F) Max. temp. (°F)

R134a HFC A1 -4.0 °F < 122.0 °F

R410A HFC A1 -4.0 °F < 122.0 °F

R513A HFC A1 -4.0 °F < 122.0 °F

R32 HFC A2L -4.0 °F < 122.0 °F

R1234ze HFO A2L -4.0 °F < 122.0 °F

Loading...

Loading...