22.11 5806712_07 43

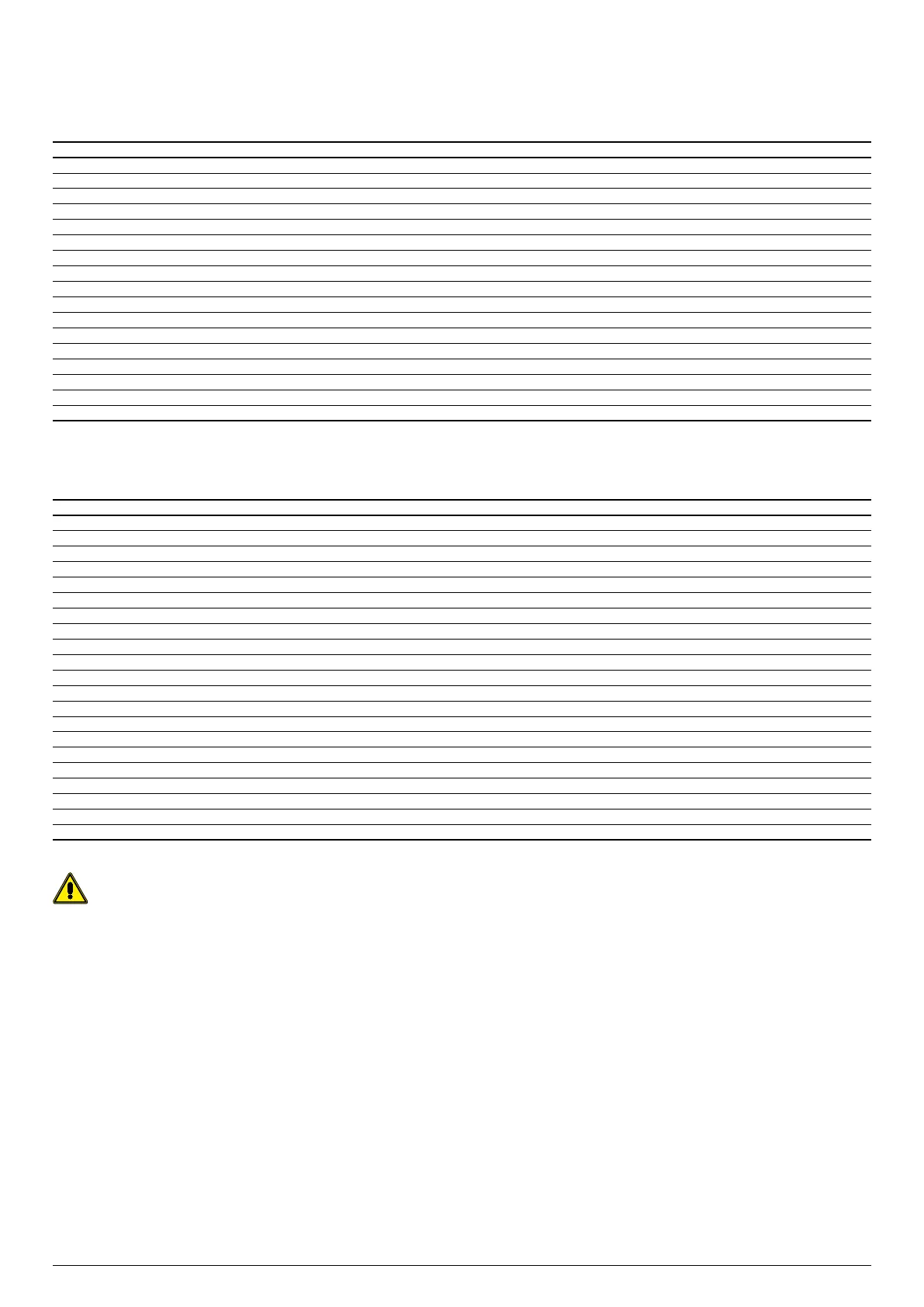

16 LIST OF THE RECOMMENDED PERIODIC INTERVENTIONS

GENERAL INTERVENTIONS

DESCRIPTION FREQUENCY

Note 3 Mths 6 Mths 12 Mths

GENERAL INTERVENTIONS

Refrigerant leak control (this operation must be performed with the frequency suggested by current European regulations) •

Unit supply voltage control •

Compressor supply voltage control •

Fan supply voltage control •

Solenoid valve control •

Pressure switch operation and calibration control, if applicable •

Pressure/temperature probe control and reading •

Control and replacement, if necessary, of the lter driers •

Compressor contactor control •

Fan contactor control, if applicable •

Heat exchanger electric heater control •

Heat exchanger coil cleaning (preferably from the inside towards the outside)

(1)

Check for the presence of rust or signs of corrosion in the components, paying particular attention to pressurised containers. In that case, replace them or use specic products • •

General unit cleaning •

Vent the hydraulic circuit and the heat exchangers, the coexistence of air and water reduces performance and can promote the formation of rust •

(1) To clean the coils, refer to the dedicated chapter.

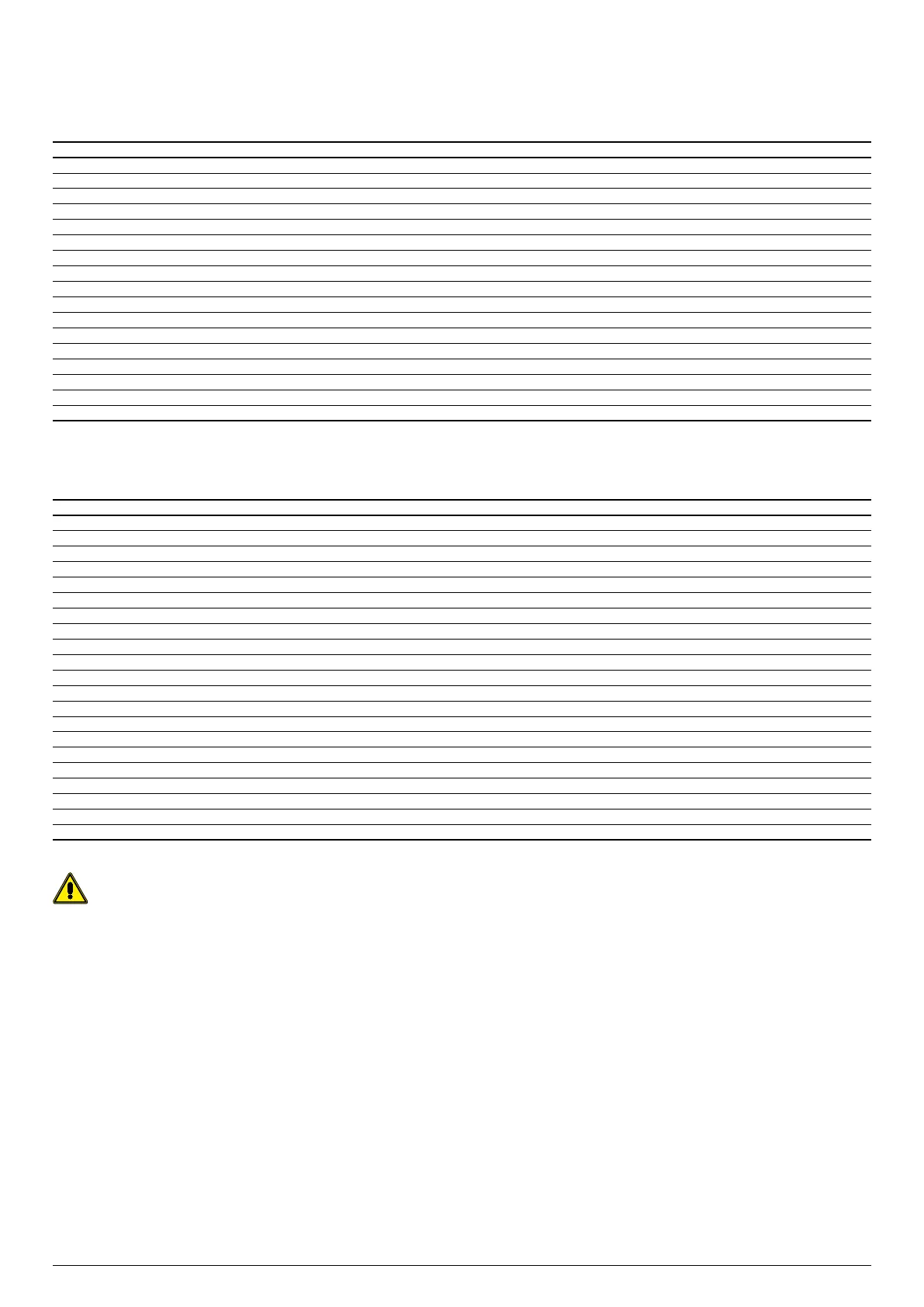

INTERVENTIONS ON THE CIRCUIT

DESCRIPTION FREQUENCY

Note 3 Mths 6 Mths 12 Mths

INTERVENTIONS ON THE COOLING CIRCUIT OPERATING WITH FULL LOAD

Measurement of the overheating temperature •

Measurement of the undercooling temperature •

Measurement of the exhaust gas temperature •

Measurement of fan input •

Measurement of compressor input •

COMPRESSOR CONTROLS

Oil level control •

Oil acidity control •

Control of proper operation of the carter heater •

Control of the oil level sensor, if present •

HYDRAULIC CIRCUIT CONTROLS

Measurement of pump input •

Check the rotor seal of the pump(s) •

Control of exible joints •

Control of the seal of the tube core exchanger heads •

Control of the proper operation and calibration of the ow switch, if present •

Control of the proper operation of the dierential pressure switch, if present •

Control the concentration of the glycol solution, if applicable (1) •

Cleaning the water lter •

(1) If the glycol must be changed, refer to the documentation provided by the supplier.

WARNING The frequency of the operations described here is only approximate, they can vary based on how the unit is used and the type of system where

it is installed. If the unit is installed in aggressive environments, we recommend reducing the intervention times.

Loading...

Loading...