39

TriScroll 600 Series Vacuum Pump

DRA

FT 6/13/11

Wiring

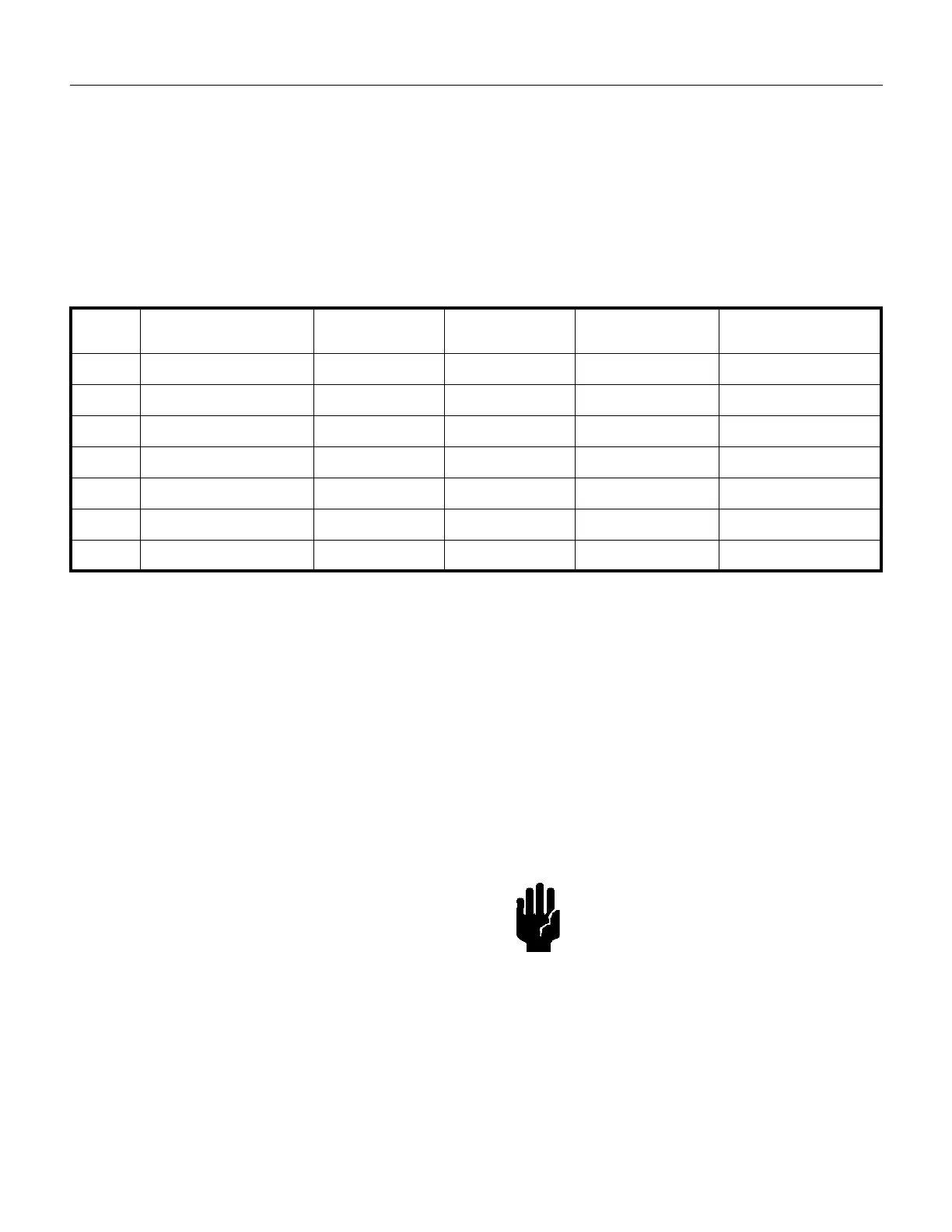

Using the data in Table 19, verify that the VPI Valve

chosen is compatible with the TriScroll supply voltage

and frequency. Then, locate the proper wiring diagram to

use (Figure 4 on page 36 or Figure 5 on page 37).

1. Remove the three screws (item 12 in Figure 3 on

page 35) that are holding the motor electrical cover

(item 13 in Figure 3).

2. Connect the VPI Valve solenoid wire leads to the

pump motor as shown in Figure 4 or Figure 5.

3. Replace the motor electrical cover and secure it using

the three screws removed in step 1. Verify that the

valve is properly grounded before applying

electrical power.

.

*

Solenoid operating voltages are lower than the TriScroll vacuum pump operating voltages in order to utilize the TriScroll motor’s inter-

nal thermal switch to actuate the VPI Valve.

Gas Ballast

The pump incorporates an automatic gas ballast to

prevent water and other condensates from accumulating

within the pump. The standard configuration is a sintered

filter installed in the 1/4" National Pipe Thread gas ballast

port (item 9 on Figure 3 on page 35). This allows enough

atmospheric air to enter the pump in order to purge

condensates while not affecting pump ultimate pressure

or pumping speed.

For applications where the ingress of atmospheric air is

undesirable, dry nitrogen at a flow rate of

≈

5 lpm can be

bled into the gas ballast port. See “Purge Kit” below.

Blocking of the gas ballast port is not recommended.

Bearing Purge

A 1/4" National Pipe Thread bearing purge port (item 6 on

Figure 3 on page 35) protects the main crankshaft

bearings in applications where large amounts of water are

being pumped. In the standard configuration, this port is

sealed.

To enable the bearing purge, dry nitrogen at a flow rate of

≈

5 lpm can be bled into the bearing purge port. This gas

supply should be maintained at 2 psig or less and must be

kept below 5 psig. See “Purge Kit” below.

Purge Kit

A purge kit (Agilent part number PTSPURGEKIT) is

available to properly purge either the bearing purge or the

gas ballast. This kit contains a flowmeter and all

necessary valving and tubing.

Table 19 VPI Valve Installation Data

Motor TriScroll Vacuum Pump

Operating Voltage

VPI Valve Part #

NW25

VPI Valve Part #

NW40

Solenoid Operating

Voltage Range

Use the following

Wiring Diagram

1 Phase 100-120 V 50/60 Hz VPI251205060 VPI401205060 90-132 V Figure 4 low voltage

1 Phase 200-230 V 50/60 Hz VPI251205060 VPI401205060 90-132 V* Figure 4 high voltage

3 Phase 200 V 50/60 Hz VPI251205060 VPI401205060 90-132 V* Figure 5 low voltage

3 Phase 230 V 50/60 Hz VPI251335060 VPI401335060 120-146 V* Figure 5 low voltage

3 Phase 380 V 50/60 Hz VPI252205060 VPI402205060 180-264 V* Figure 5 high voltage

3 Phase 415 V 50/60 Hz VPI252205060 VPI402205060 180-264 V* Figure 5 high voltage

3 Phase 460 V 50/60 Hz VPI252665060 VPI402665060 239-293 V* Figure 5 high voltage

CAUTION The bearing purge port has been

disabled on the TriScroll 600

model S4800309. Use of this port

could cause internal damage to

the pump.

Loading...

Loading...