32

CHECKING & CALIBRATION

THIS CHAPTER IS VERY IMPORTANT. Here are instructions to check the GradeLight

calibration. Remember that the laser is a precision instrument and that it is important that it

be calibrated and in proper condition. The accuracy of work is completely the responsibility

of the user. The instrument should be checked before beginning each job, and especially

after the instrument has taken a sharp jolt or been dropped, or when temperature changes

greater than 50° F (28° C) have occurred.

Checking Level Accuracy

Select a reasonable level area. Set up the GradeLight on a stable surface. The cross axis

vial should be centered and the legs adjusted so the unit is level.

It will be easier to adjust the laser to strike stake B in Figure 1 by using the single centerline

leg in the front (beam end) or by using the trivet with height adjustable rod.

After the unit has self-leveled, set the grade at 0/000%.

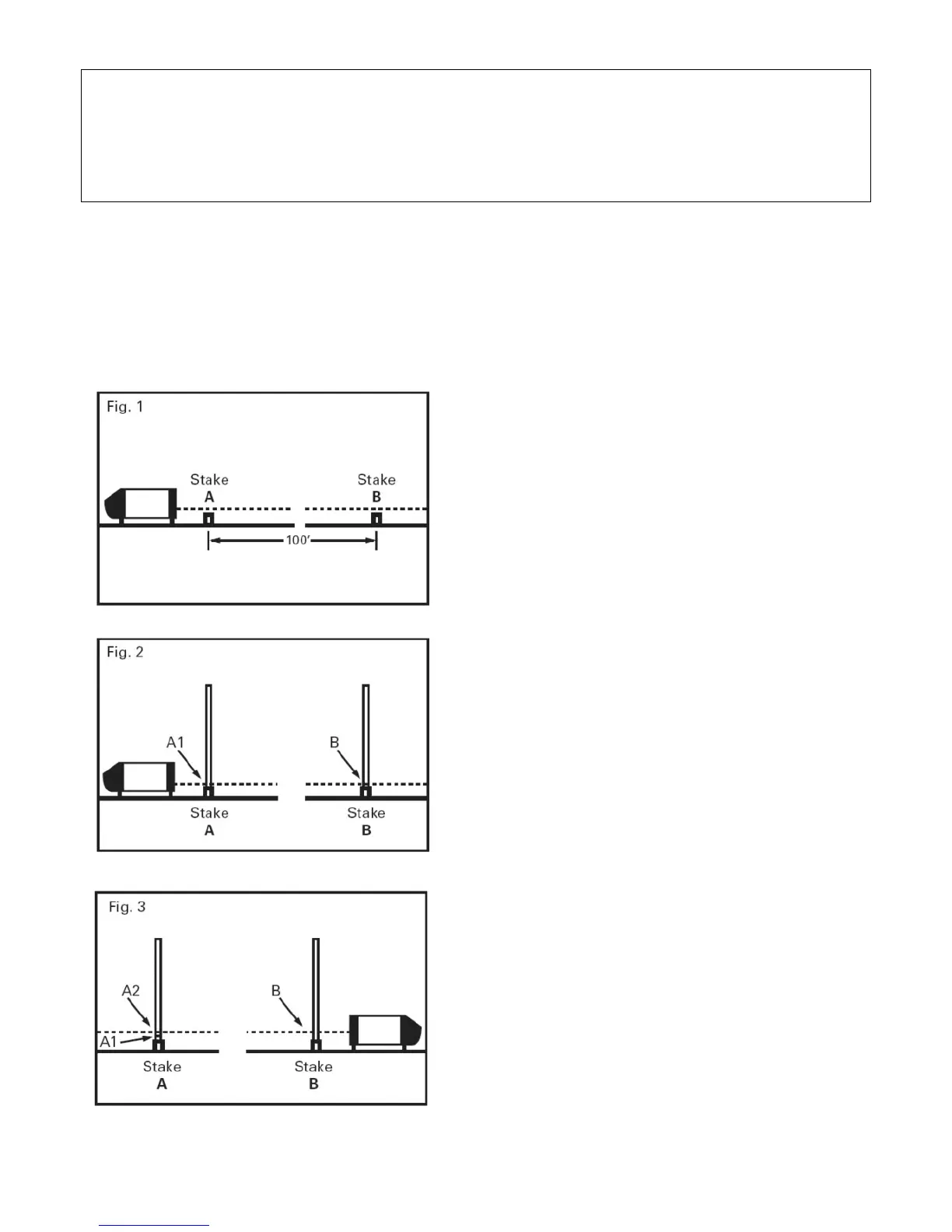

1. Establish two benchmarks:

Figure 1: Drive two stakes (A & B) in line with

the laser beam, but low enough for the beam

to pass over both stakes. Stake A should be

about 1 foot (0.3 m) from the unit, and stake B

about 100 feet (30 m) away.

2. Check the instrument:

Figure 2: Place a short 2 X 4 or something similar

on stake A, and mark where the center of the

beam strikes. Call the mark A1.

Place the same 2 X 4 on stake B and again mark

where the center of the beam strikes. Call this

mark B.

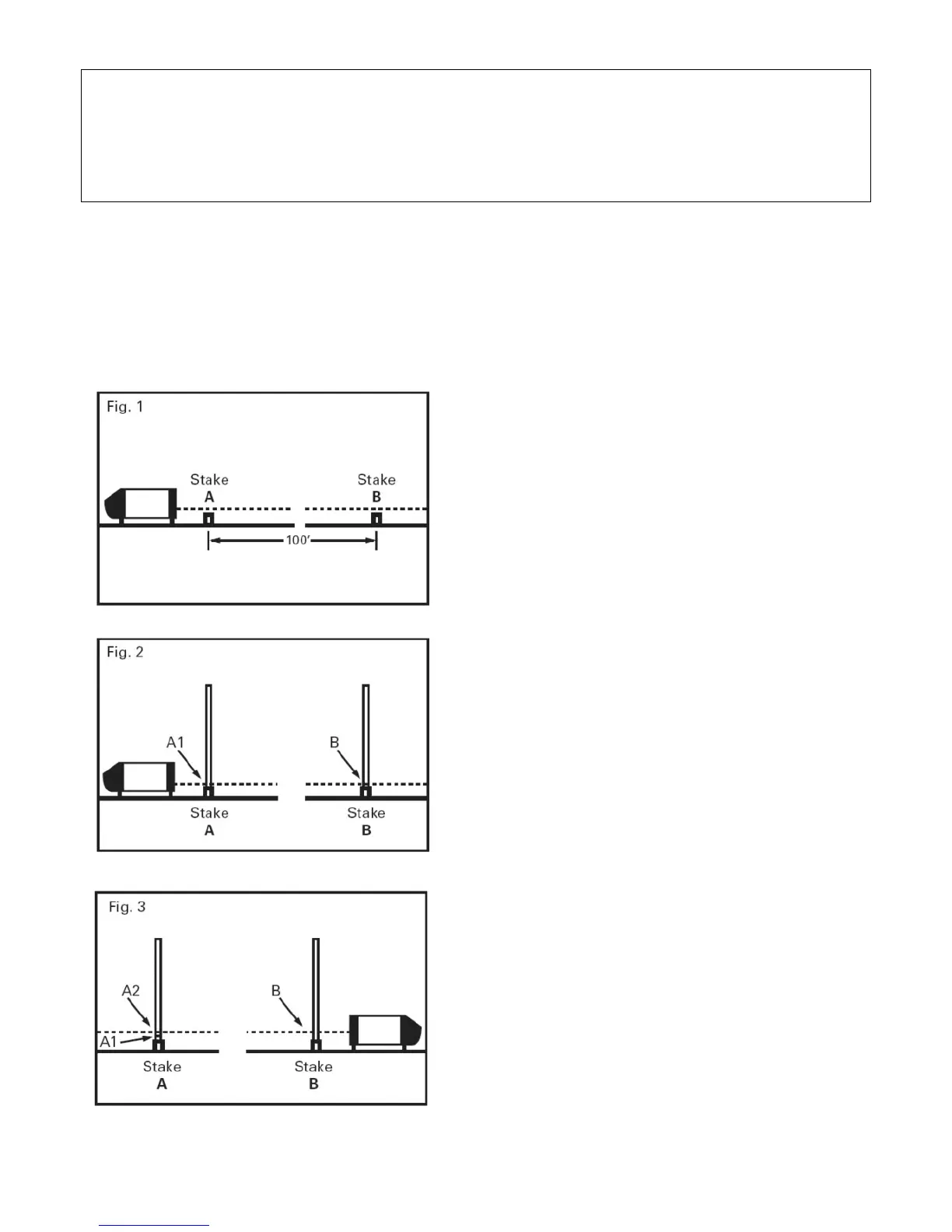

3. Move the laser to the far side of stake B

(Figure 3) so the beam will cross over both

stakes as before, but in reverse order.

a. Be sure the height of the unit is set to that

when the 2 X 4 is placed on stake B, the

beam will strike at mark B.

b. Now place the 2 X 4 on stake A. Make a

second mark (A2) where the center of the

beam strikes.

At 100 feet, the marks should be no more than

1/8 inch apart (at 30 m, no more than 3 mm

apart). This is within the stated accuracy of

±1/16 inch at 100 feet.

If the marks are close enough, the beam is

accurately projecting level. If they are not close

enough, take it to an authorized AGL service

center for calibration, or adjust the unit using the

following procedure.

Loading...

Loading...