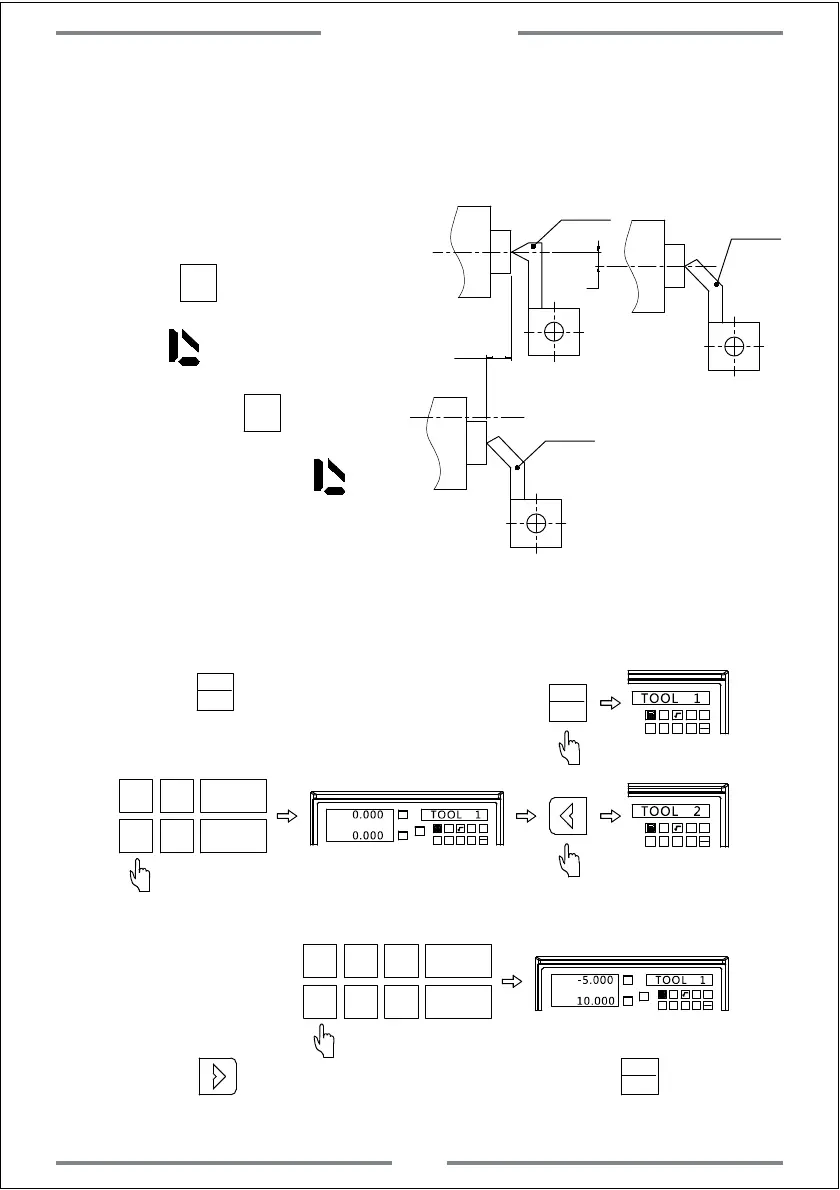

3. Number the tool,and memorize its position data which is basing the

reference tool.

10

5

Tool 1

Tool 2

Tool 2

±

±

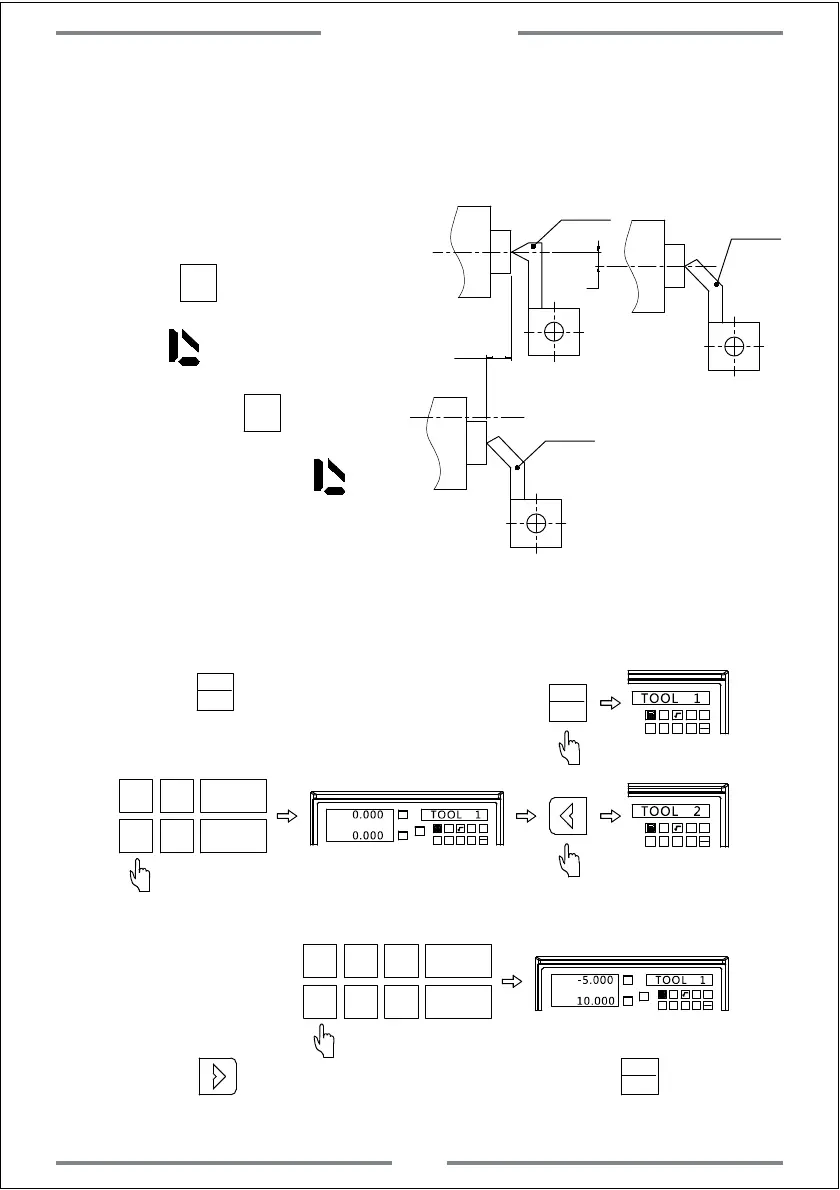

The operation of setting the tool are as the following:

Step 1: Move the tool 1 to zero point and zero the value.Set the tool 1 as

reference tool under ABS model.

Step 2: Press to enter the tool setting

1 32

-

+

CLS

Arc

sin

TOOL

TOOL 1

sin

TOOL

sin

TOOL

Step 3: Input the coordinate of tool.

1 32

-

+

CLS Arc

sin

TOOL

TOOL 2

X

0

T

Y

0

T

X0

Y0

X

1 32

-

+

CLS Arc

sin

TOOL

0.000 TOOL 1

0.000

Step 4: Input the coordinate of tool 2.

X 5

T

Y

0

T

X0

Y0

X

1 32

-

+

CLS Arc

sin

TOOL

-5.000 TOOL 1

10.000

±

1

Step 5: Press to input the coordinate of next tool.Press to exit the

tool setting.

sin

TOOL

4. When machining,user could input

or switch the tool number.Move the

carriage until the value of both X

and Y axis become 0.

5. Press 10 times.The right

window will display TL-OPEN with

a mark .This indicates the tool

offset function has been

activated.Press 10 times

again.The right window will display

TL-CLOS,and the mark

will disappear.This indicates the tool

offset function has been turn off.

figure B

Special Function

36

Loading...

Loading...