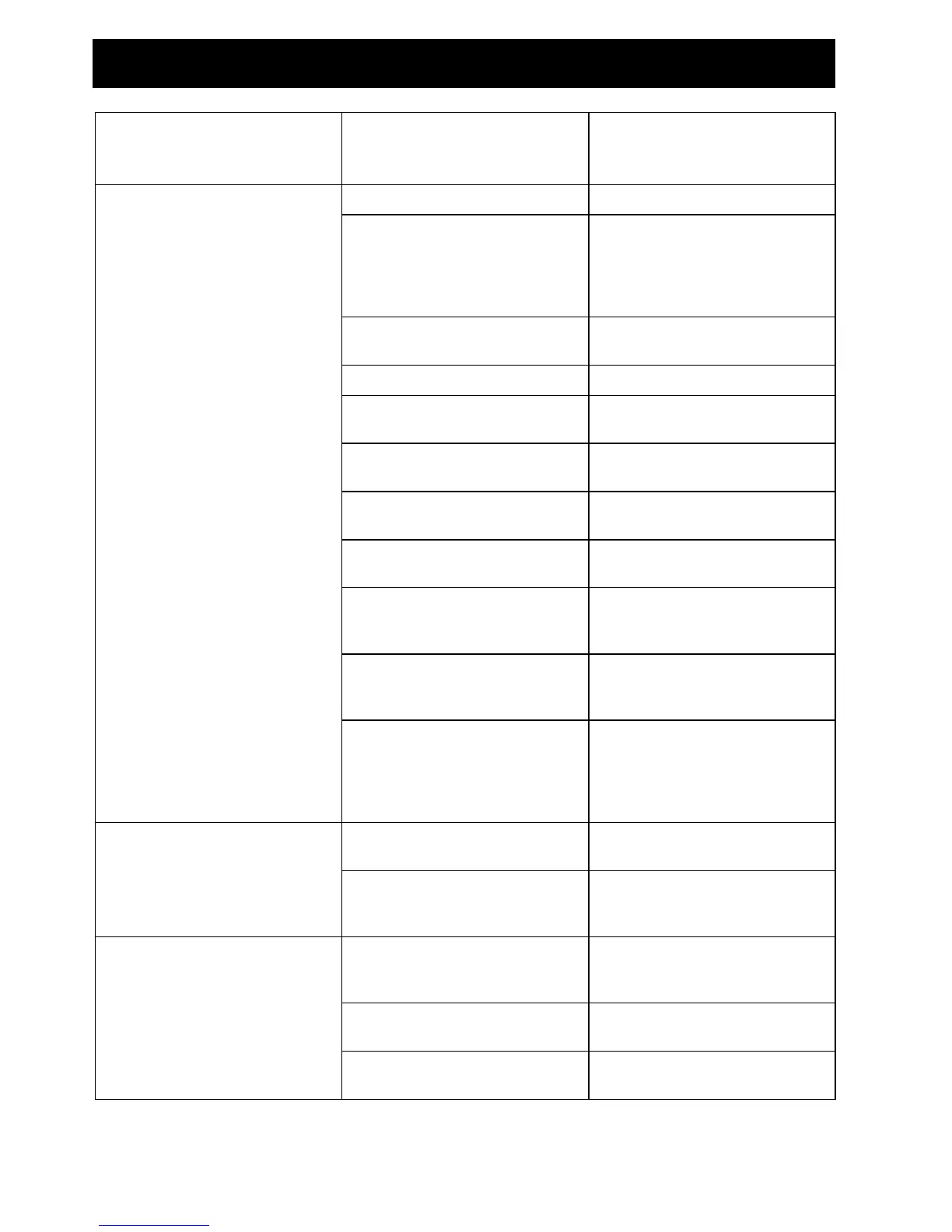

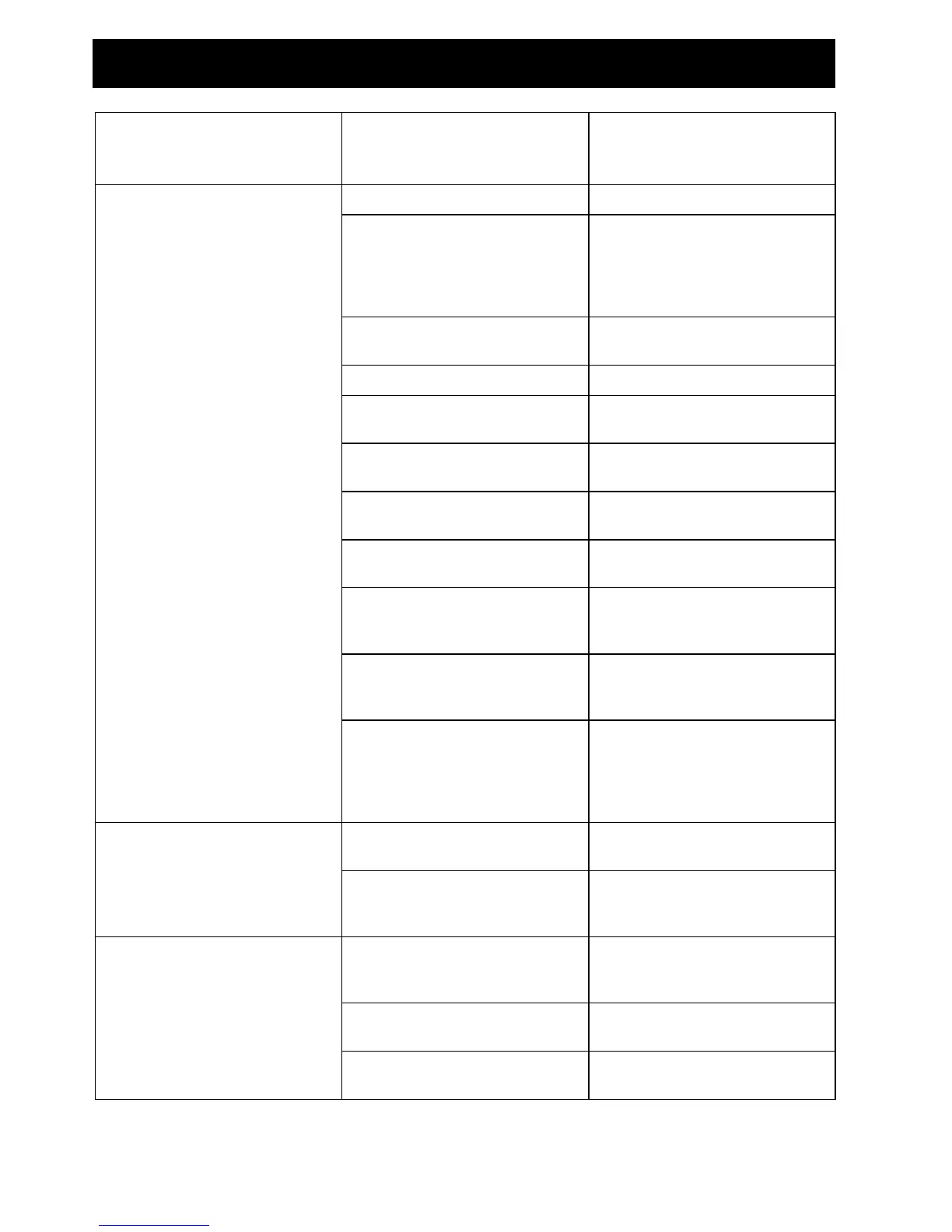

Troubleshooting

24 3A4180C

Pump output is low Pump rod damage. Repair pump. See pump manual.

Low stall pressure. Turn pressure knob fully clockwise.

Make sure pressure control knob is

properly installed to allow full

clockwise position. If problem

persists, replace pressure control.

Piston packings are worn or

damaged.

Replace packings. See pump

manual.

O-ring in pump is worn or damaged. Replace o-ring. See pump manual.

Intake valve ball is packed with

material.

Clean intake valve. See pump

manual.

Large pressure drop in hose with

heavy materials.

Reduce overall length of hose.

Check extension cord for correct

size.

See Extension Cords, page 10.

Loose motor brushes and terminals. Tighten terminal screws. Replace

brushes if leads are damaged.

Worn motor brushes. (Brushes

must be 1/2 in. [13mm] minimum

length).

Replace brushes.

Broken and misaligned motor brush

springs. Rolled portion of spring

must rest squarely on top of brush.

Replace spring if broken. Realign

spring with brush.

Motor brushes are binding in brush

holders.

Clean brush holders, remove

carbon dust with a small cleaning

brush. Align brush lead with slot in

brush holder to assure free vertical

brush movement.

Motor runs but pump does not

stroke

Connecting rod assembly

damaged. See pump manual.

Replace connecting rod assembly.

See pump manual.

Gears or drive housing damaged. Inspect drive housing assembly and

gears for damage and replace if

necessary.

Excessive paint leakage into throat

packing nut

Throat packing nut is loose. Remove throat packing nut spacer.

Tighten throat packing nut just

enough to stop leakage.

Throat packings are worn or

damaged.

Replace packings. See pump

manual.

Displacement rod is worn or

damaged.

Replace rod. See pump manual.

Problem

What to Check

If check is OK, go to next

check

What to Do

When check is not OK,

refer to this column

Loading...

Loading...