200 Series Tooling Alcoa Fastening Systems

16

T

T

ROUBLESHOOTING

ROUBLESHOOTING

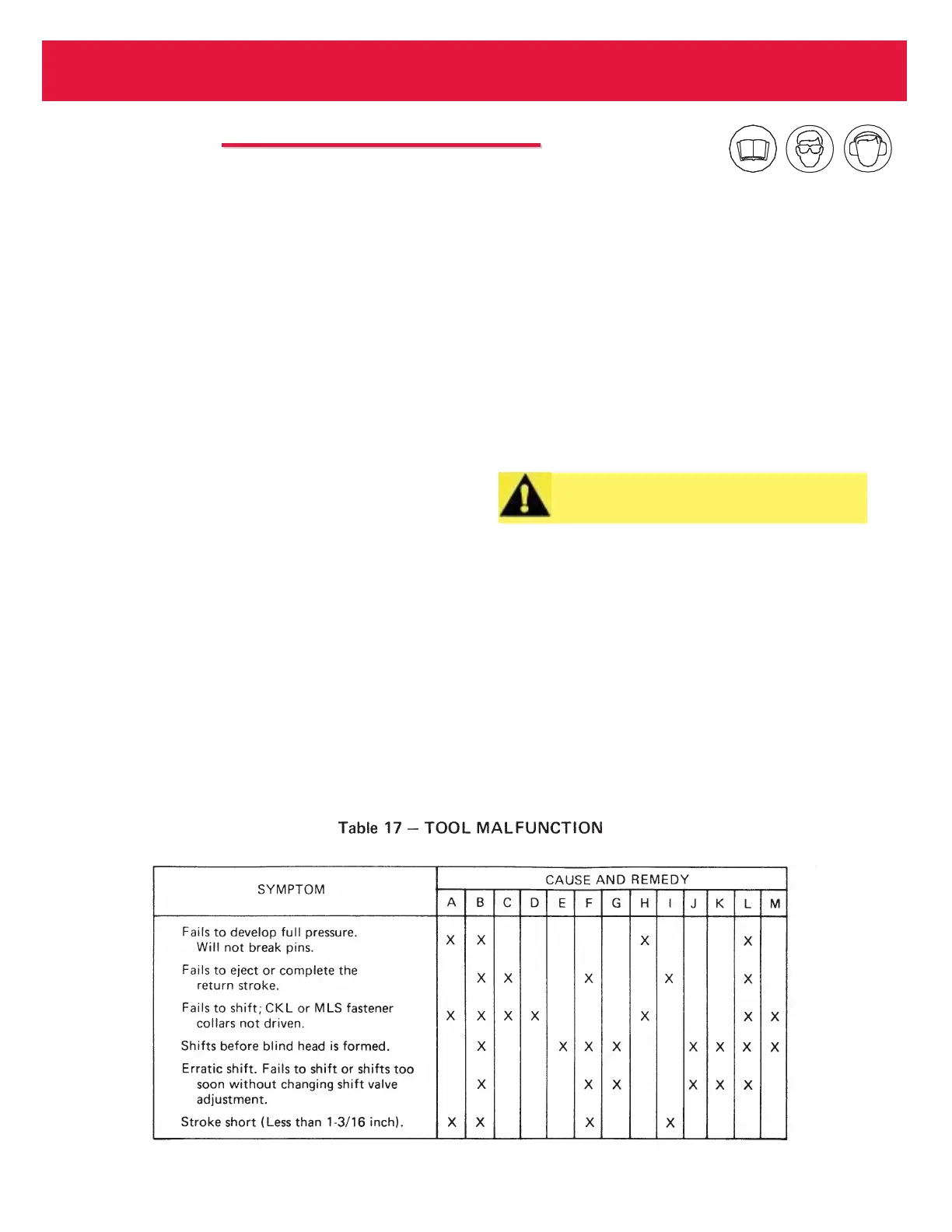

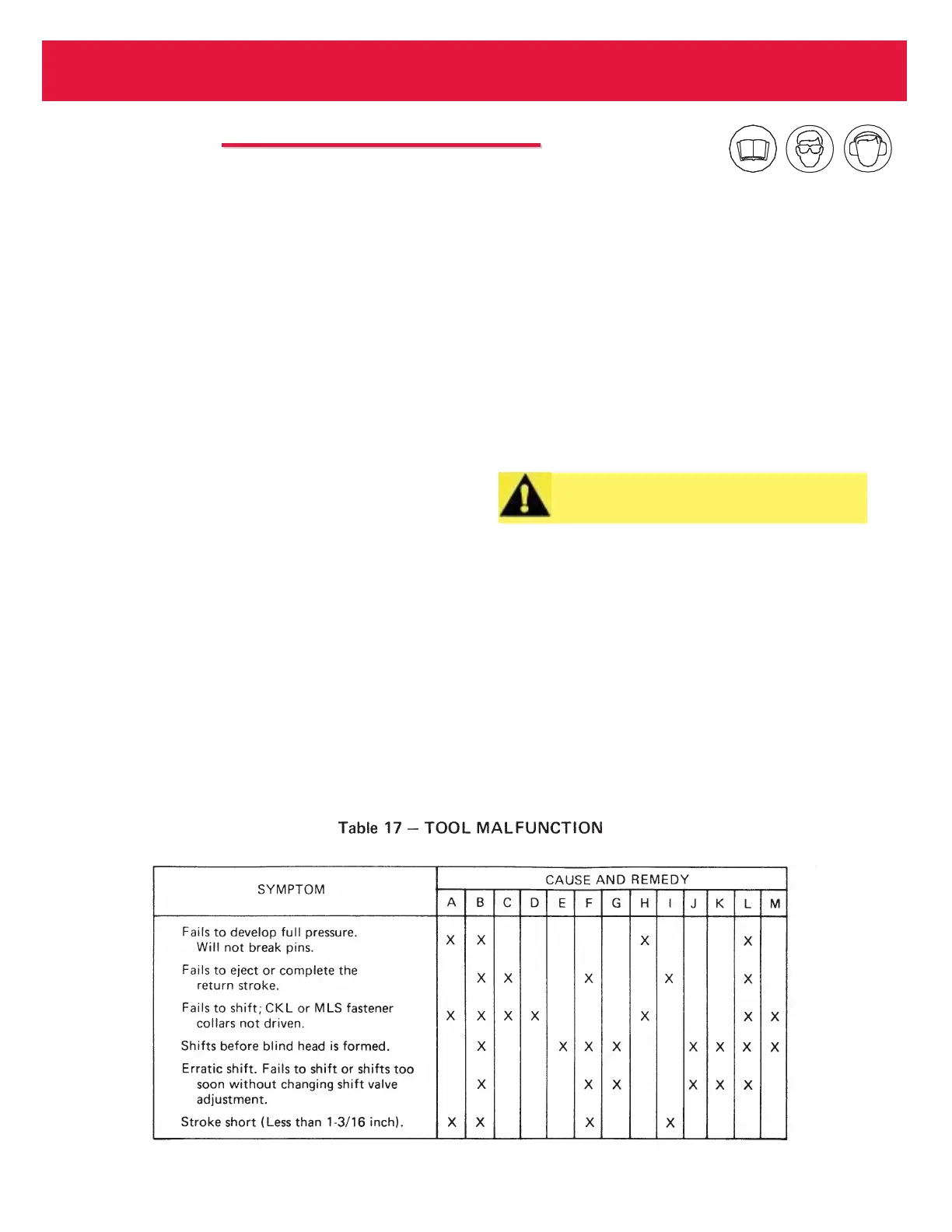

TOOL MALFUNCTION CAUSE AND

TOOL MALFUNCTION CAUSE AND

REMEDY

REMEDY

A. Air supply pressure low. Air pressure of 90-100 psi

required.

B. Air in hydraulic system. Refill and bleed tool per

instructions.

C. Check nose assembly for completeness and prop-

er installation per instructions.

D. Shift valve adjustment set too high (13-7). Readjust

counter-clockwise per instructions.

E. Shift valve adjustment set too low (13-7). Re adjust

clockwise per instructions.

F. Relief valve (13-8) not sealing. Check 3/16 inch

ball (2-47) and seat (2-3) for foreign particles.

Clean if dirty. Reseat ball by tapping against brass

seat. Replace ball or seat if damaged.

G. Check valve (13-9) for leakage. Clean and reseat

ball (2-51) by tapping. If ball or seat (2-2A) are

damaged, replace.

H. Bleed screw (2-40) not backed out to stop (13-11).

Balance valve (2-33) stuck in open position or for-

eign material between valve and seat. Free valve

and remove any foreign particles. If valve or seat

(2-4) are damaged, replace.

I. Check valve (13-10) for leakage. Clean valve and

reseat ball (2-51) by tapping. If ball or seal (2-2B)

are damaged, replace.

J. Shift sleeve (4-27) loose (13-12). Tighten with

Wrench 100878.

K. Shift valve seat (4-13) not sealing (13-13). Replace

seat if foreign particles are imbedded in seal, or if

seat is damaged.

L. Shift plunger (4-10) sticky in sleeve (4-7). Remove

plunger from sleeve. If plunger or sleeve bore is

scored, replace (13-13).

M. Extreme temperature variation. Adjust shift valve

(13-7) as necessary.

CAUTION: Make certain that Valve compo-

nents are not magnetized.

Loading...

Loading...