Maintenance

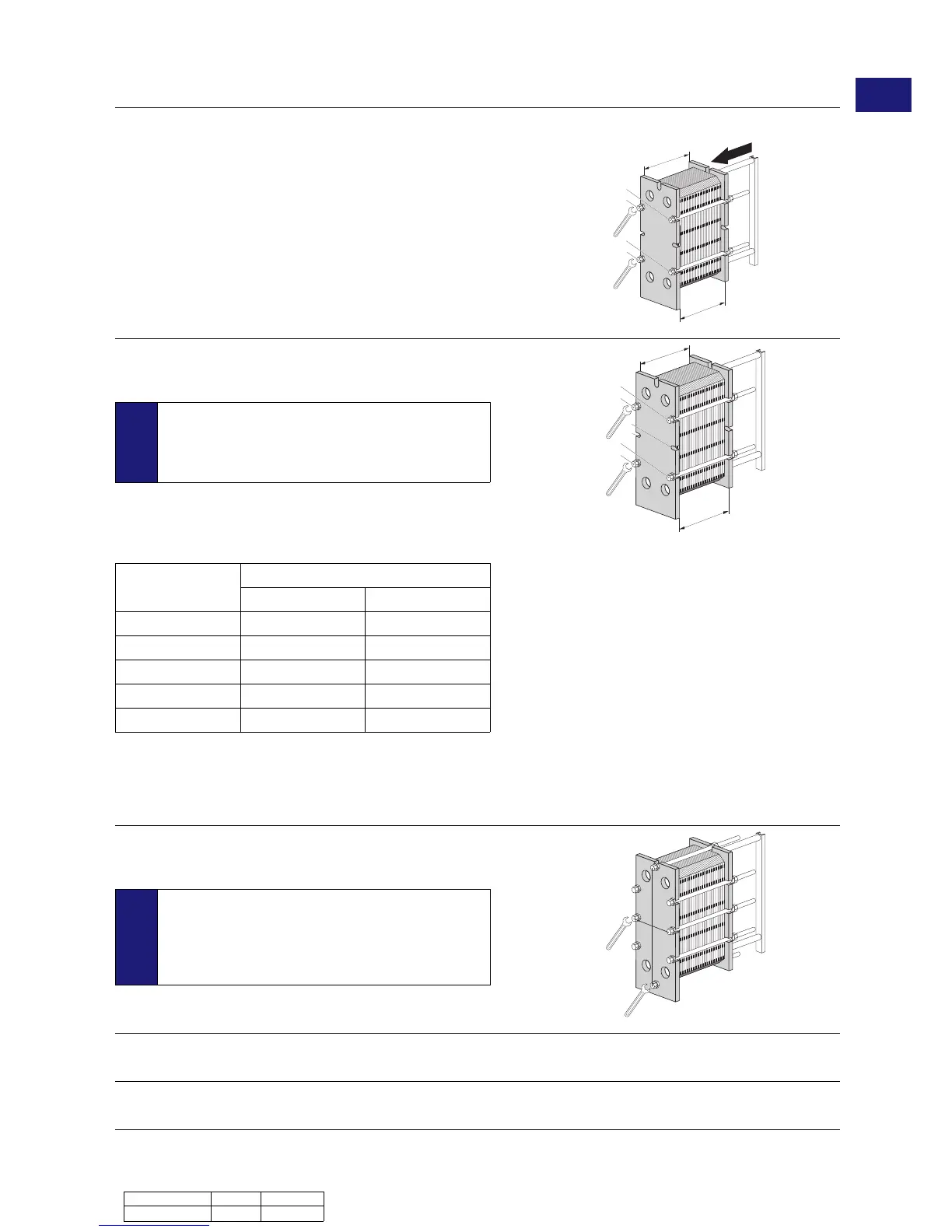

Step 6

Press the plate pack together. Posit ion the fou r tightening bolts

according to the figure.

Tighte n the four bolts (1), (2), (3), (4) until the plate pack

measure A is 1.10 making sure the frame plate and pressure

plate are parallel when closing.

Step 7

Tighte n the four bolts (1), (2 ), (3), (4) evenly until dimension A

has bee n reached.

Note!

For TL6: Add the middle bolts and continue to tighte n 1 0

m m or less with bolt 5 and 6. Then tighte n the remaining

bolts with the same length. Repeat these steps until

dimension A is achieved.

When a pneumatic tightening device is used, see table below for

maximum torque. Measure dimension A during tig htening.

Bolt with washerBolt size

Nm kpm

M 10 32 3.2

M 16 135 13.5

M 20 265 26.5

M 24 450 45

M 30 900 90

For manual tightening, the tightening torque has to be estimated.

If dimension A cannot be reached:

• Ch eck the number of plat es and the dimension A.

• Ch eck that all the nuts and bearing boxes are running freel y.

If not, clean and lubricate, or r eplace.

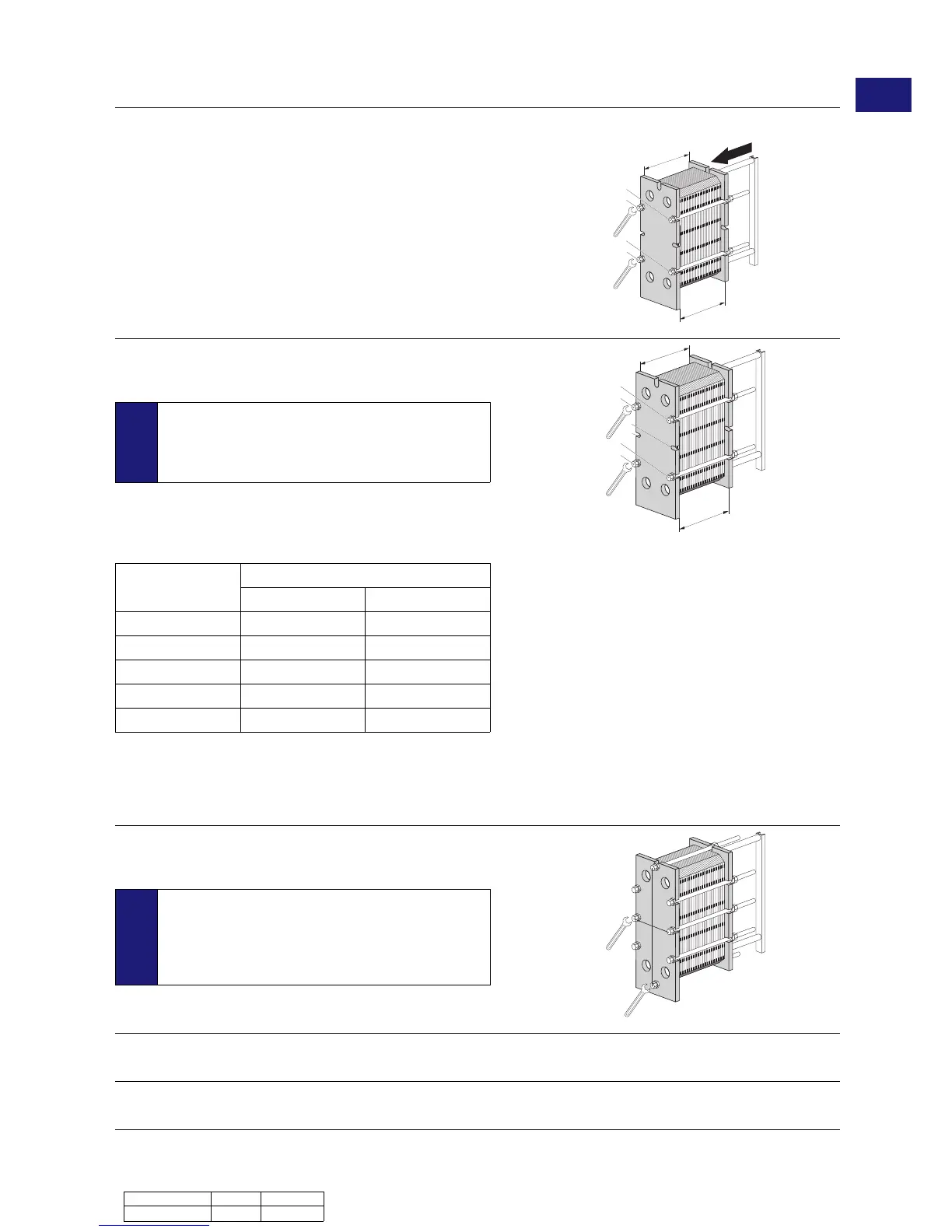

Step 8

Mount the remaining locking bolts and check measurement A

on both sides, top and bottom.

Note!

For TL6: When using frame ASME standard! Heat

excha ngers with pressure vess el code ASME are

equipped with top and bottom bolt s. Tighten those bolts

after th e procedure above has been finished or slightly

before the dimension A is reached.

Step 9

Mount protection sheets (if provided).

Step 10

Connect pipes .

Document ID La nguage Edition

3490010217 EN 2016-06 Instruction Ma nual - Plate Heat Exchan gers 27

EN

Loading...

Loading...