Rockwell Automation Publication 2080-UM002K-EN-E - March 2019 69

Communication Connections Chapter 5

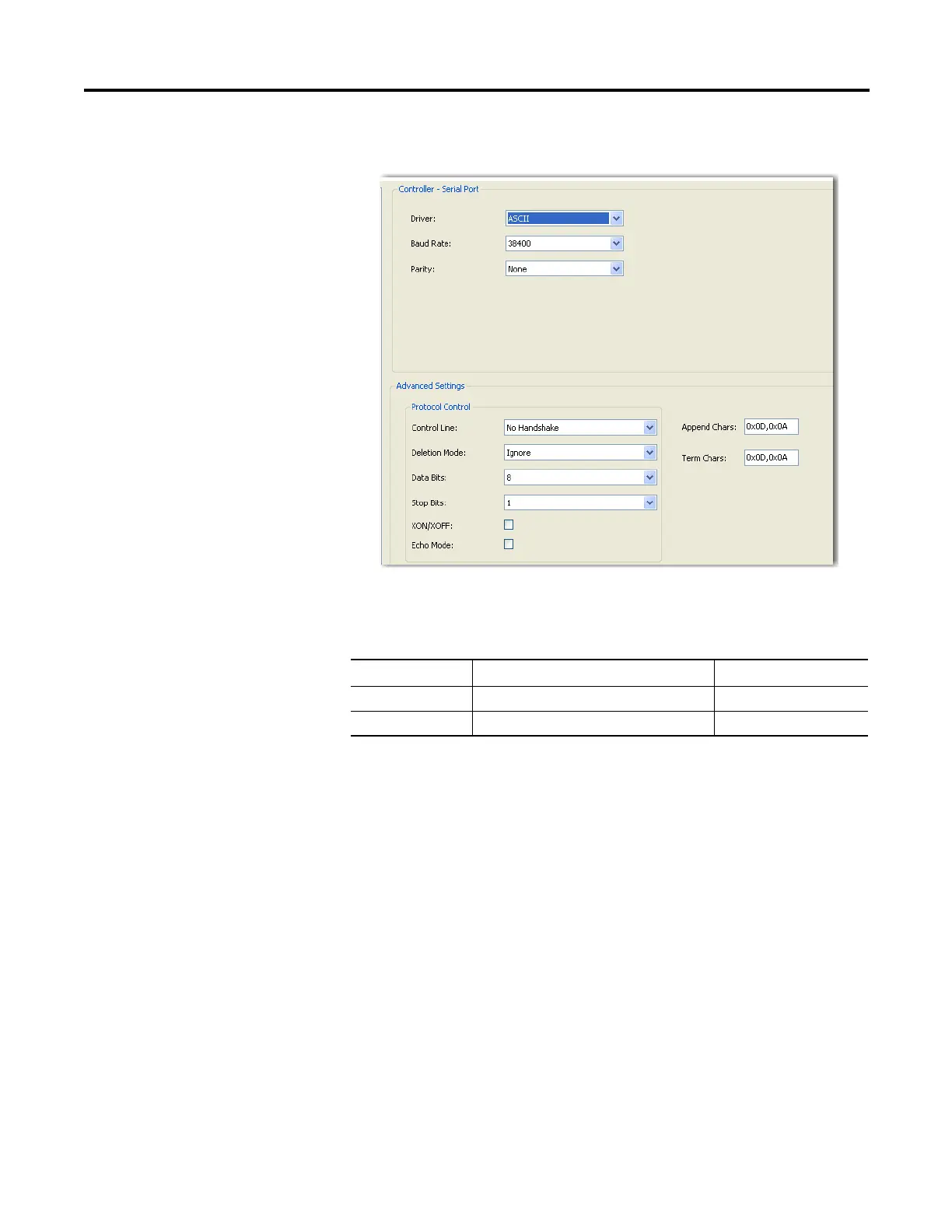

2. Select ASCII on the Driver field.

3. Specify baud rate and parity.

ASCII Parameters

Parameter Options Default

Baud Rate 1200, 2400, 4800, 9600, 19200, 38400 19200

Parity None, Odd, Even None

Loading...

Loading...