Motor Control Modes 51

Motor Control Modes [Motor Cntl Sel] selects the output mode of the drive. The choices are:

• Custom Volts/Hertz

Used in multi-motor or synchronous motor applications.

• Fan/Pump Volts/Hertz

Used for centrifugal fan/pump (variable torque) applications to achieve

maximum energy savings.

• Sensorless Vector

Used for most constant torque applications. Provides excellent starting,

acceleration and running torque.

• Sensorless Vector w/Economizer

Used for additional energy savings in constant torque applications that have

constant speed reduced load periods.

• Flux Vector

Used when high performance speed regulation or torque regulation is required.

• Adjustable Voltage

Typically used for non-motor applications such as resistive loads, welding

equipment and power supplies, but also linear motors.

The following table shows the performance differences between V/Hz, Sensorless

Vector and Flux Vector.

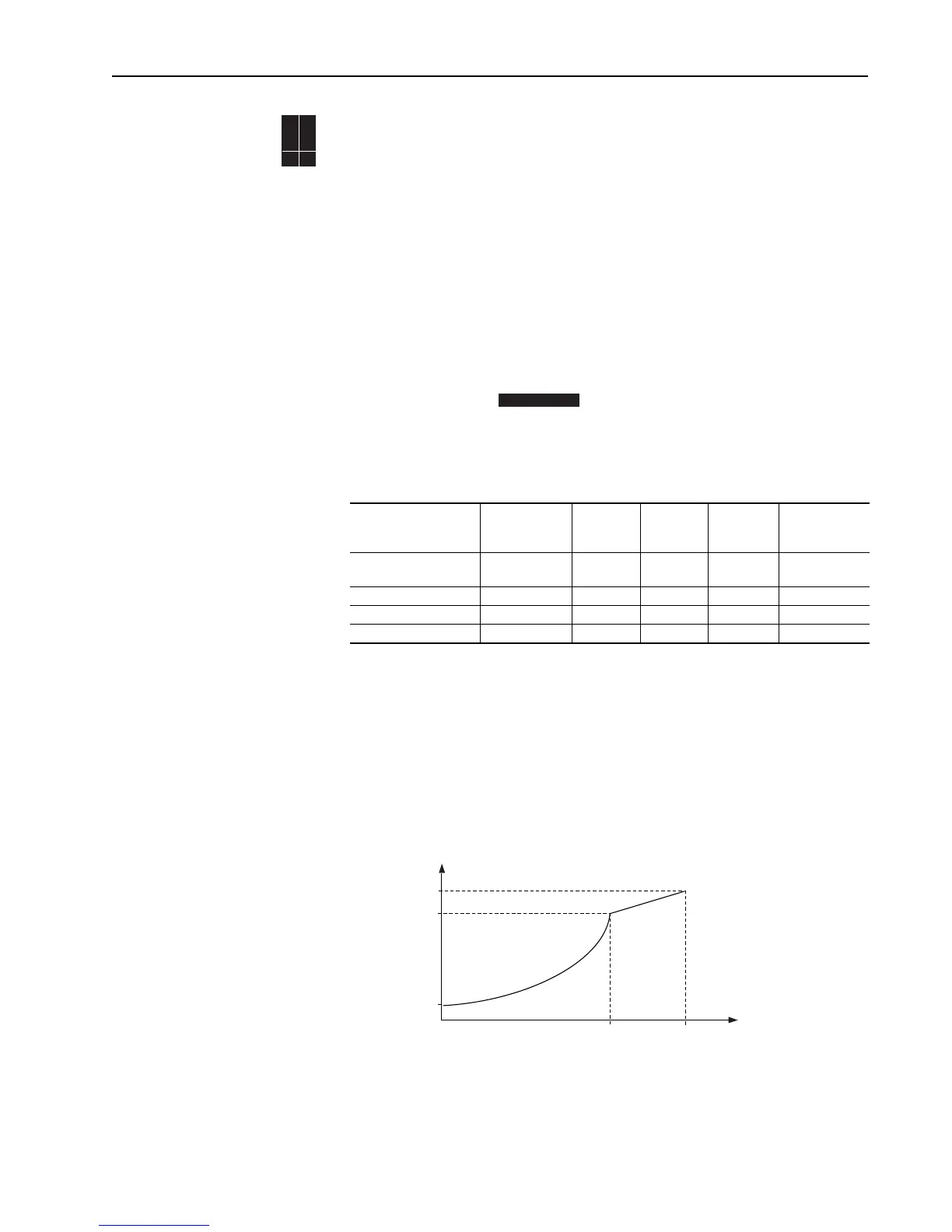

Volts/Hertz

Volts/Hertz operation creates a fixed relationship between output voltage and

output frequency. The relationship can be defined in two ways.

1. Fan/Pump

When this option is chosen, the relationship is 1/x

2

. Therefore;

for full frequency, full voltage is supplied and for 1/2 rated frequency,

1/4 voltage is applied, etc. This pattern closely matches the torque requirement

of a variable torque load (centrifugal fan or pump – load increases as speed

increases) and offers the best energy savings for these applications.

70EC

700VC

700H

✔✔

Torque Mode

Fan/Pump and

Custom V/Hz

with Slip Comp

SVC with

Slip Comp

SVC with

Feedback

Flux Vector

without

Feedback

Flux Vector

with Feedback

Speed Regulation

(% of base speed)

0.5% 0.5% 0.1% 0.1% 0.001%

Operating Speed Range 40:1 80:1 80:1 120:1 1000:1

Speed Bandwidth 10 rad/sec 20 rad/sec 20 rad/sec 50 rad/sec ≥125 rad/sec

Torque Regulation N/A N/A N/A ≤10% ≤5%

700VC

ONLY

Maximum Voltage

Maximum

Frequency

Base Voltage

(Nameplate)

Base Frequency

(Nameplate)

Run Boost

Loading...

Loading...