508433-01Issue 2345Page 26 of 70

Combustion Air Inducer (B6) and Cold End Header Box

All A97UH2E units use a two-speed combustion air inducer

to move air through the burners and heat exchanger during

heating operation. The blower uses a 120VAC motor.

The motor operates during all heating operation and is

controlled by integrated control control A92. The inducer

also operates for 15 seconds before burner ignition (pre-

purge) and for 5 seconds after the gas valve closes (post-

purge). The inducer operates on low speed during rst-

stage heat, then switches to high speed for second stage

heat.

The combustion air inducer is installed on the cold end

header box (CEHB). The cold end header box is a single

piece made of hard plastic. The box has an internal

channel where the combustion air inducer creates negative

pressure at unit start up. The channel contains an orice

used to regulate ow created by the combustion air inducer.

The box has pressure taps for the combustion air inducer

pressure switch hoses. The pressure switch measures the

pressure dierential across the cold end header box orice

or dierence in the channel and the box. If replacement

is necessary the gaskets used to seal the box to the

vestibule panel and the combustion air inducer to the

box, must also be replaced.

A pressure switch measures the pressure dierential across

the CEHB orice to prove inducer operation. The CEHB

orice will be dierent for each model. When the proving

switch opens, the furnace control (A92) immediately closes

the gas valve to prevent burner operation.

Combustion Air Inducer Pressure Switch (S18) (Figure

14)

A97UH2E series units are equipped with a dual combustion

air pressure switch (rst and second stage) located on the

CEHB. The switch is connected to the cold end header box

by means of exible silicone hoses. It monitors negative

dierential pressure across the cold end header box orice.

The switches are a single-pole single-throw pressure

switches electrically connected to the integrated control.

The purpose of the switches is to prevent burner operation

if the combustion air inducer is not operating, the inlet or

exhaust pipes or heat exchanger are restricted.

On heat demand (rst or second stage) the switch senses

that the combustion air inducer is operating. It closes a

circuit to the integrated control when pressure across the

CEHB orice becomes greater then the switch set point.

Set points vary depending on unit size. See Table 9. Both

pressures sensed by the switches are negative relative to

atmospheric pressure. If the inlet or exhaust pipes, or the

heat exchanger become obstructed, the switch senses the

loss of dierential pressure and opens the circuit to the

furnace integrated control and gas valve. A bleed port on

the switch allows relatively dry air in the vestibule to purge

switch tubing, to prevent condensate build up.

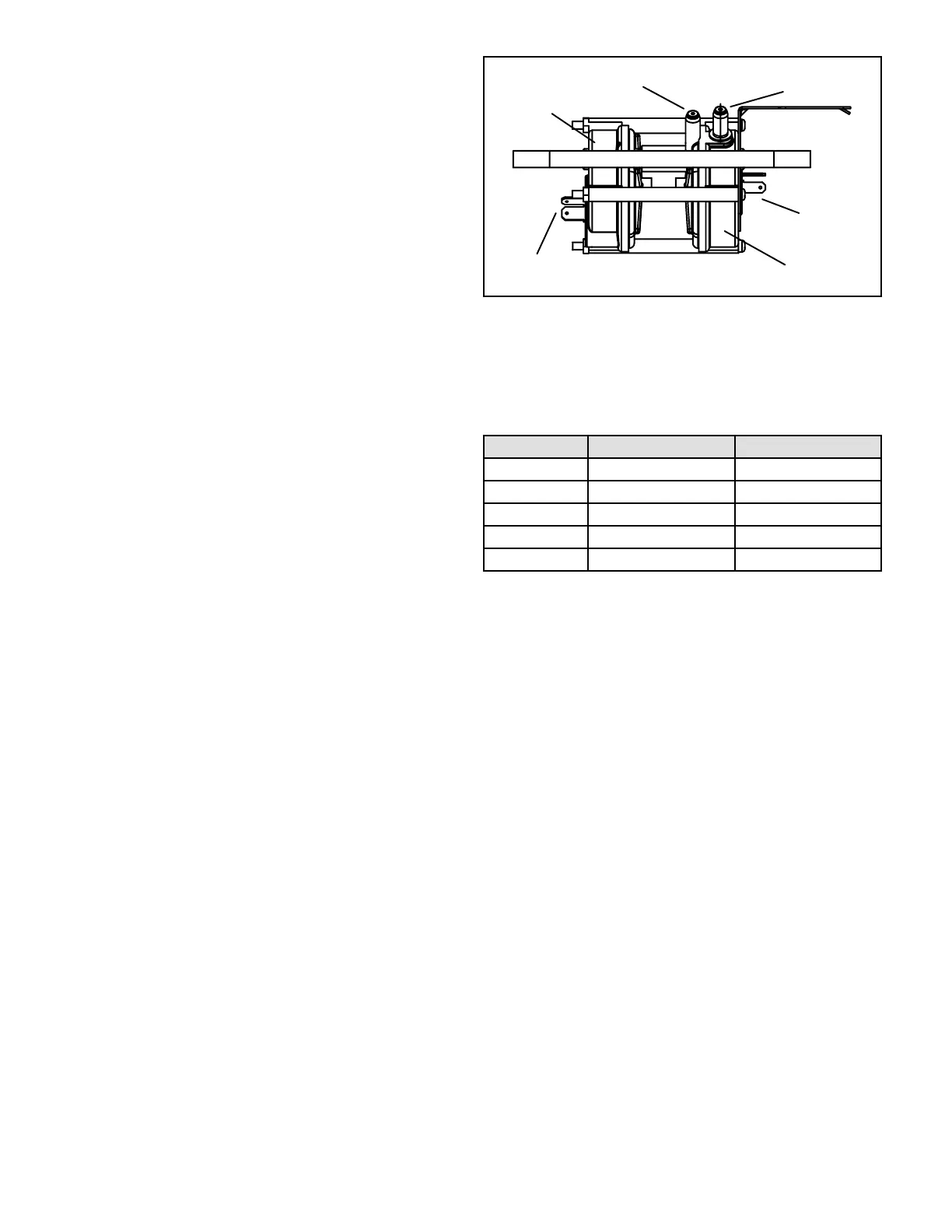

Figure 14. Combustion Air Inducer Pressure Switch

3/16 Terminals

Low Fire Switch

High Fire Switch

1/4

" Terminals

Tap (negative - )

Tap (positive +)

NOTE: The switch is factory set and is not eld adjustable.

It is a safety shut-down control in the furnace and must

not be by-passed for any reason. If switch is closed or

bypassed, the control will not initiate ignition at start up.

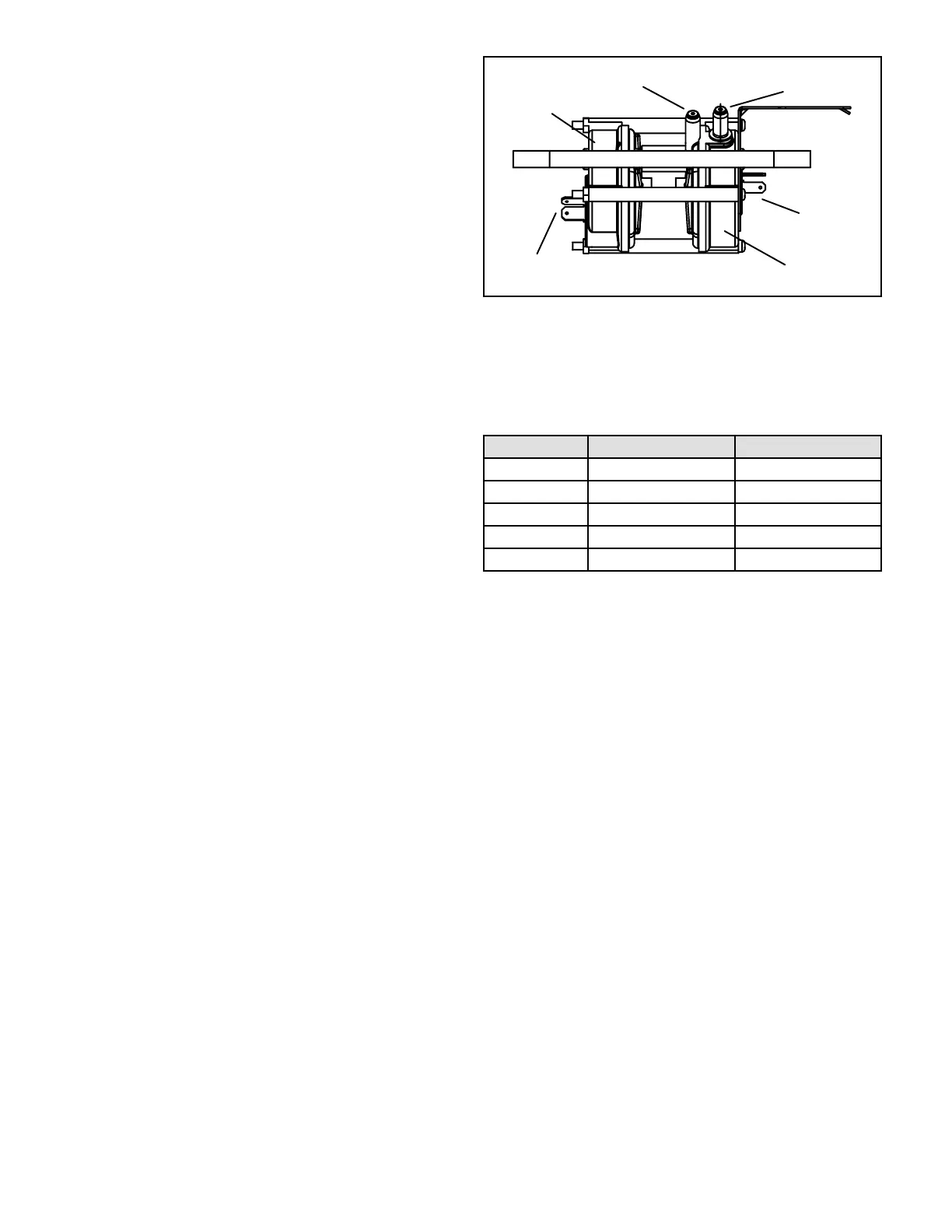

Unit Set Point Low Heat Set Point High Heat

030 0.40 0.70

045 0.50 0.80

070 0.55 0.95

090 0.50 0.90

110 0.55 1.00

Table 9. 0 - 4,500 ft.

Loading...

Loading...