508433-01Issue 2345Page 52 of 70

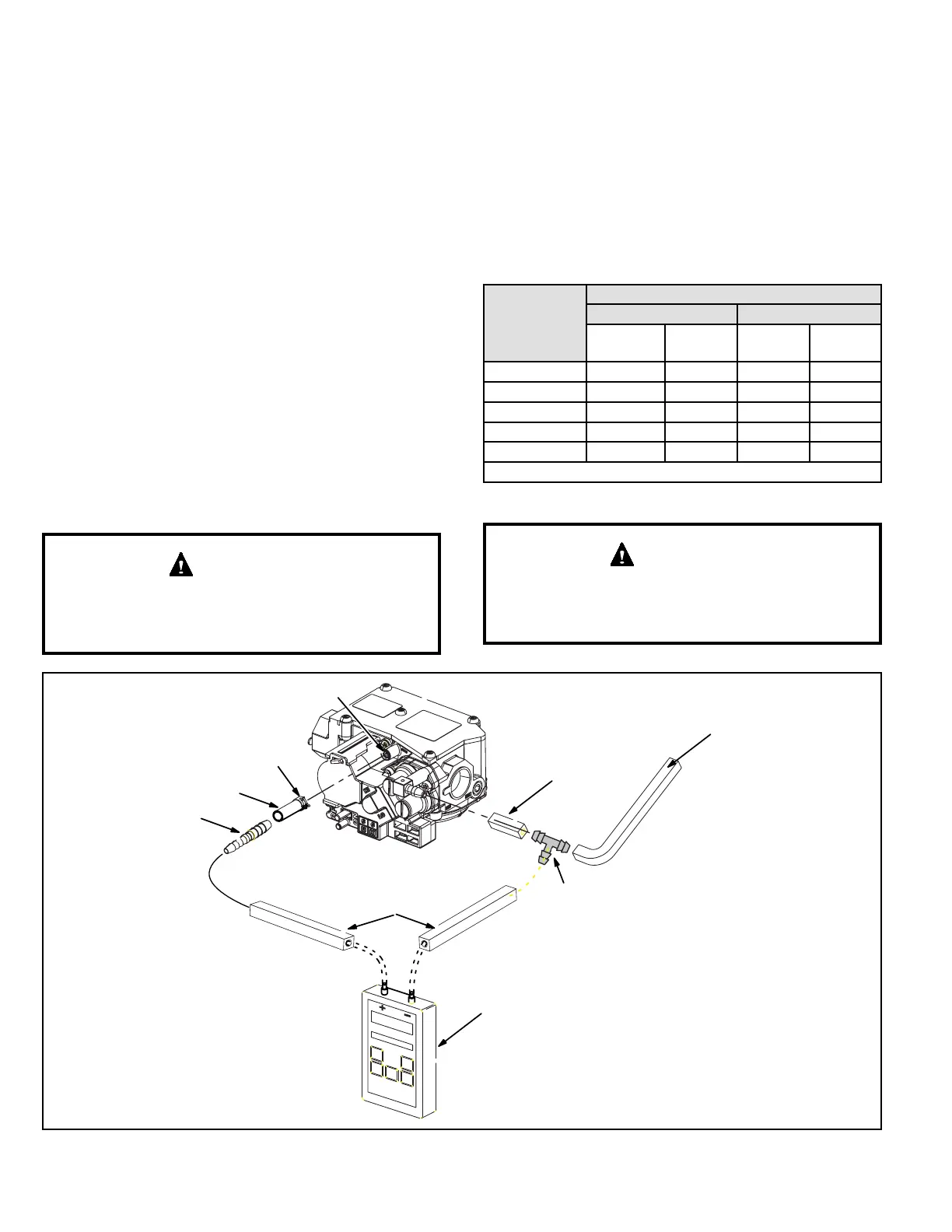

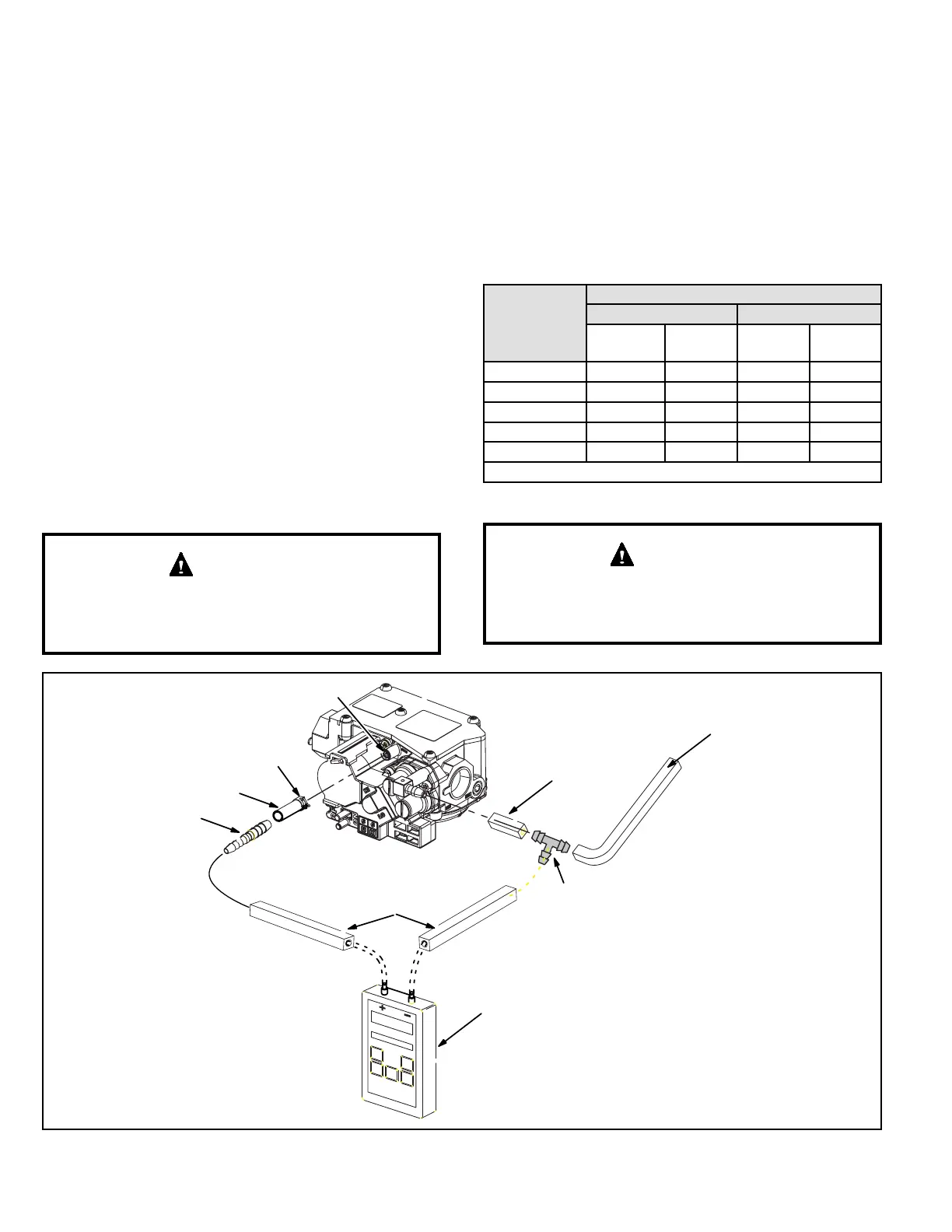

1. Connect the 5/16” round tubing to the manifold post.

Secure with the clamp.

2. Connect the reducer tting to the 5/16” round tubing

followed by a piece of 10” length square tubing.

3. Connect the other end of the square tubing to the “+”

positive side of the measuring device.

4. Take the 2” length square tubing, tee, 10” length of

square tubing and tee into the gas valve regulator vent

hose. Connect to the measuring device negative “-”

side.

5. Ignite unit on low re and let run for 5 minutes to allow

for steady state conditions.

6. After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

Table 18.

7. If necessary, make adjustments. Figure 50 shows

location of high re and low re adjustment screws.

8. Repeat steps 5, 6 and 7 on high re. See values in

Table 18.

9. Shut unit o and remove manometer as soon as an

accurate reading has been obtained.

10. Start unit and perform leak check. Seal leaks if found.

For safety, connect a shut-o valve between the

manometer and the gas tap to permit shut o of gas

pressure to the manometer.

IMPORTANT

Gas Flow (Approximate)

Furnace should operate at least 5 minutes before checking

gas ow. Determine time in seconds for two revolutions of

gas through the meter. (Two revolutions assures a more

accurate time.) Divide by two and compare to time in Table

16. If manifold pressure matches Table 18 and rate is

incorrect, check gas orices for proper size and restriction.

Remove temporary gas meter if installed.

NOTE: To obtain accurate reading, shut o all other gas

appliances connected to meter.

Capacity

Seconds for One Revolution

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

Dial

-30 120 240 300 600

-45 80 160 200 400

-70 55 110 136 272

-90 41 82 102 204

-110 33 66 82 164

Natural-1000 btu/cu ft LP-2500 btu/cu ft

Table 16. Gas Meter Clocking Chart

For safety, shut unit o and remove manometer as soon

as an accurate reading has been obtained. Take care to

replace pressure tap plug.

IMPORTANT

Manifold Post

Clamp

5/16” Round

Hose

Reducer

Fitting

10” Long

Square

Tubing

2” Long

Square Tubing

Tee

Gas Valve Regulator

Vent Hose

(to burner box)

Measuring Device

Figure 52. Manifold Pressure Check Setup

Loading...

Loading...