26

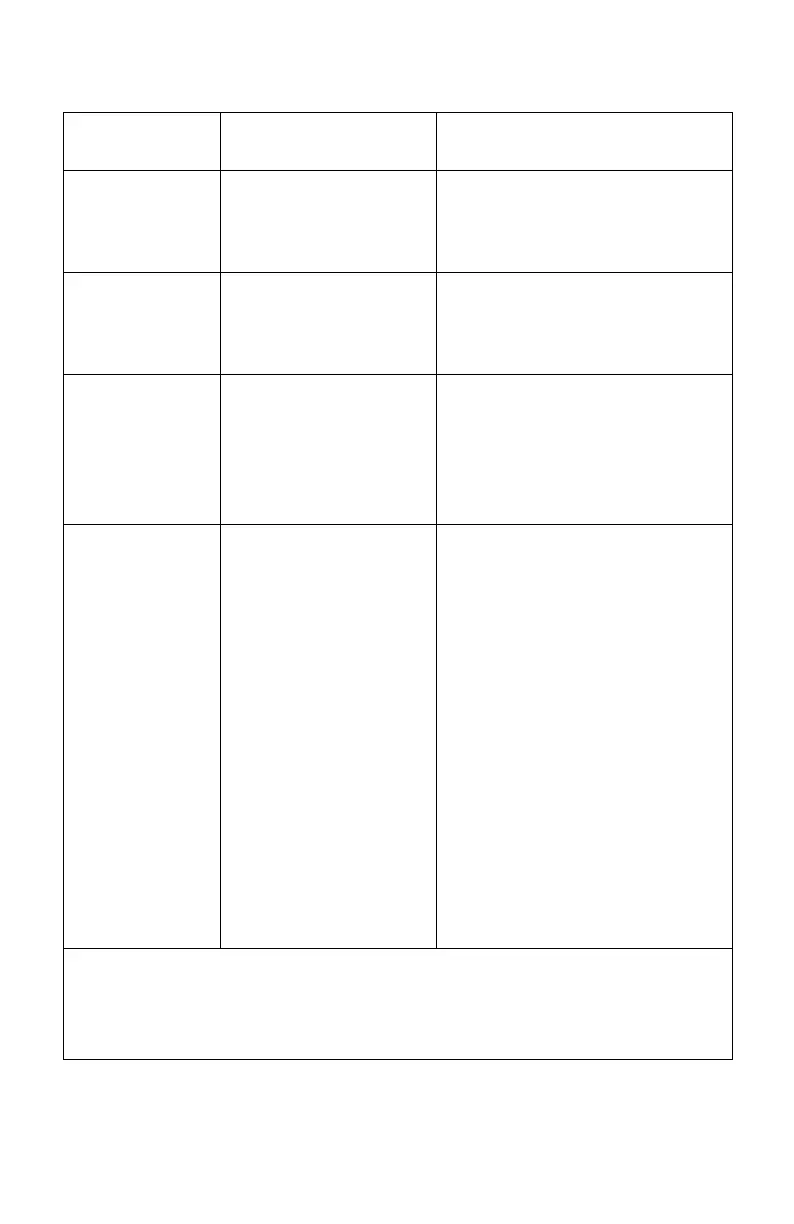

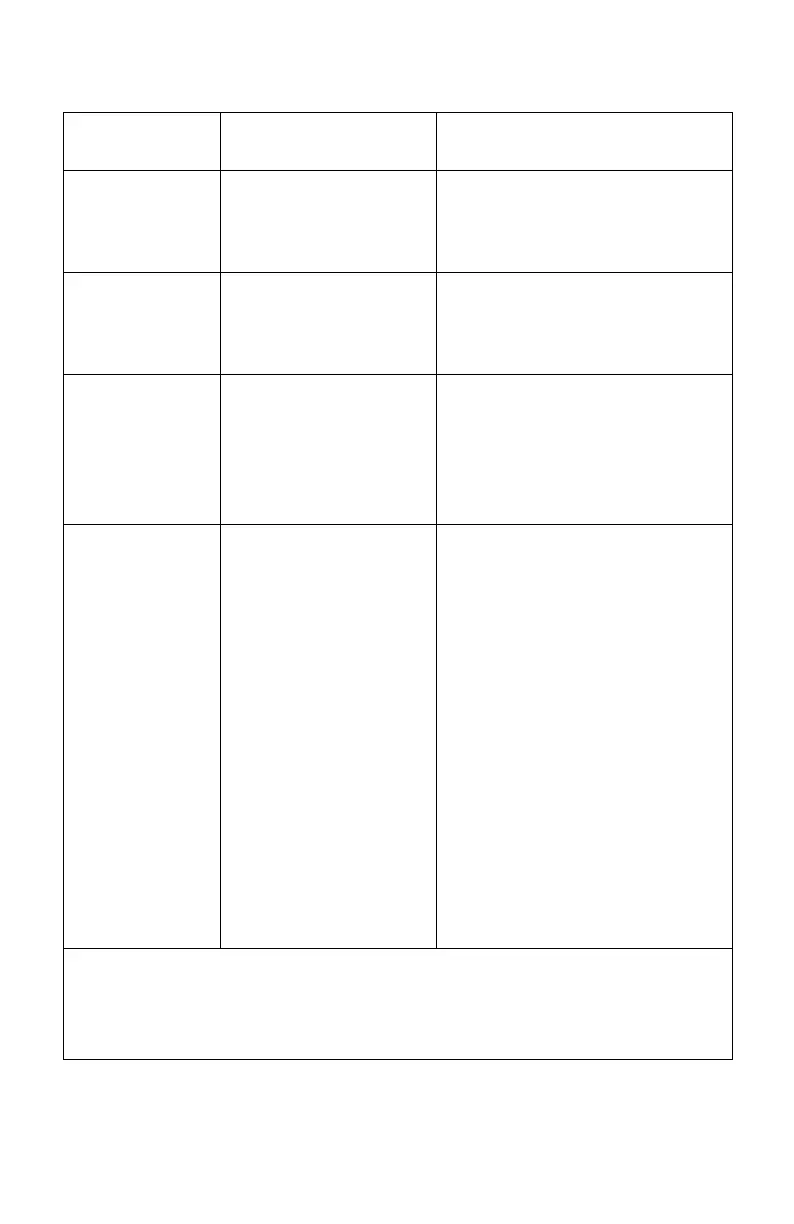

Table 4–1. Measurements

Component or

Subassembly

Required Inspections Limits

Flywheel

Housing

Bore Diameter 16.125–16.130 in.

(409.58–409.70 mm)

Bore Eccentricity* 0.020 in. (0.51 mm) T.I.R.

Face Squareness* 0.020 in. (0.51 mm) T.I.R.

Crankshaft Hub

and/or Adapter

Converter Pilot

Diameter

1.703–1.705 in.

(43.26–43.31 mm)

Face Squareness 0.0005 in. (0.013 mm) T.I.R.**

Eccentricity

†

0.010 in. (0.25 mm) T.I.R.

Flexplate

Check for Radial

Cracks

None Permitted

Check for Elongated

Mounting Holes

None Permitted

Check for Any Signs of

Distress and/or Wear

None Permitted

Mounted

Flexplate

Axial Location Flatness

—AT 540/AT 542/

AT 545 models with

converter build date

stamp before 9/84

1.600–1.740 in.

(40.64–44.19 mm)

—AT 540/AT 542/

AT 545 models with

converter build date

stamp of 9/84

or later

1.581–1.741 in.

(40.16–44.22 mm)

—AT 543 models 1.600–1.721 in.

(40.64–43.71 mm)

—AT 1500 models 2.715–2.875 in.

(68.96–73.03 mm)

Flatness

—Formed Plates

†† 0.039 in. (0.99 mm)

—Flat Plates 0.157 in. (3.99 mm)

* Limits are for installed engines.

** T.I.R. per inch of diameter.

† Eccentricity with respect to crankshaft center of rotation.

†† A formed flexplate will not be flat, but may have raised areas at the bolt holes and/or have offset

bends in the plate.

Loading...

Loading...