32

5–6. CONNECTING COOLER, VACUUM LINES, AIR LINES

• Connect the lines from the transmission to the cooler forming a transmission

fluid-to-water counterflow in the cooler. Vertical-mounted coolers require the

transmission to-cooler line to be connected to the bottom port in the cooler to

avoid air-locking the cooler.

• Keep the lines away from exhaust pipes and components that cause chafing.

Avoid kinks and sharp bends. Tighten the cooler SAE No. 8 line fittings that

thread into the transmission housing to 15–22 lb ft (20–30 N·m).

• If a vacuum modulator is used, connect the vacuum modulator line at the

intake manifold.

• If an air modulator is used, connect the air modulator control line at the

control.

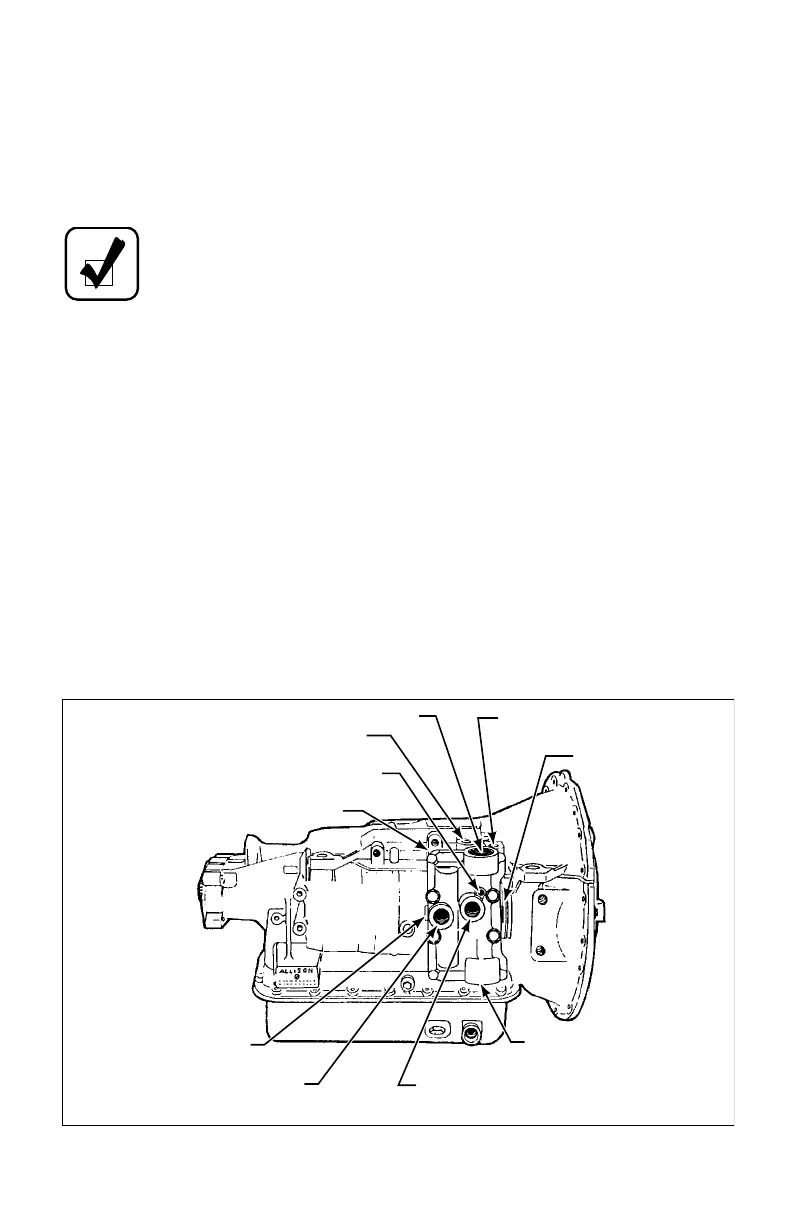

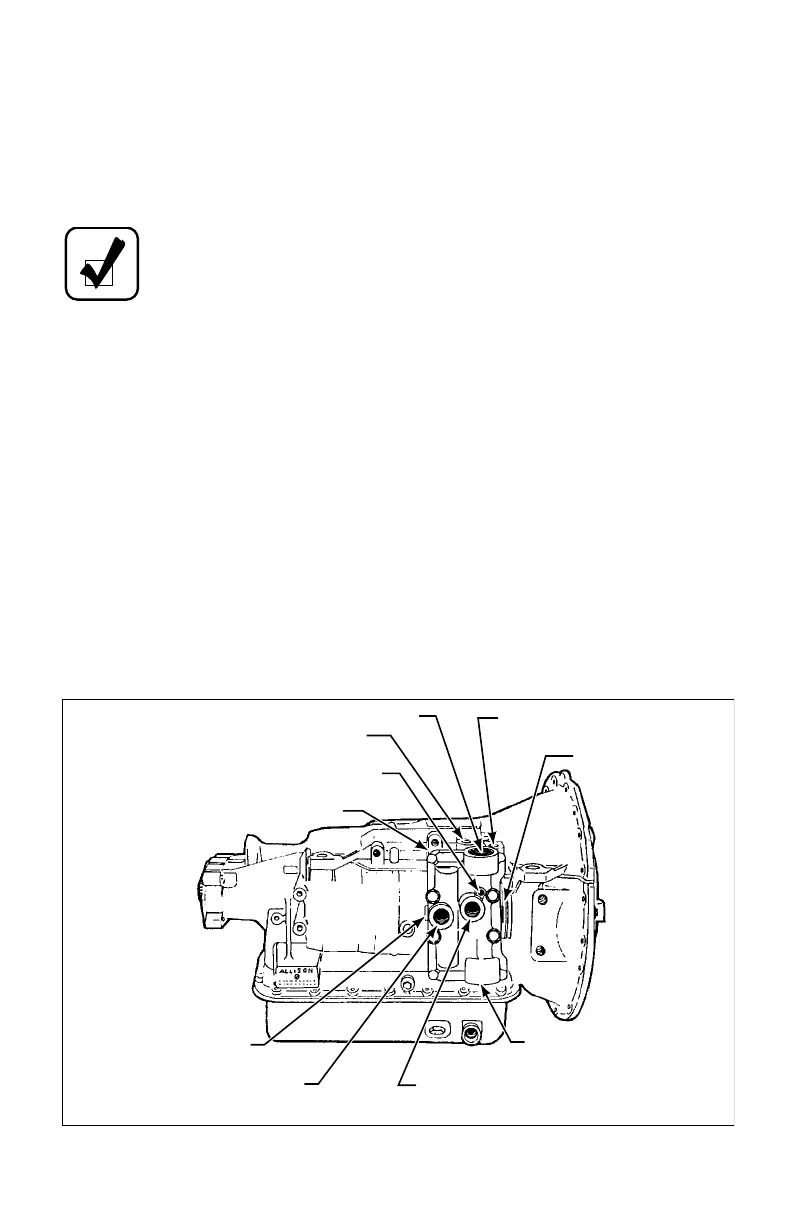

5–7. CONNECTING RETARDER CONTROLS

• Connect the wiring harness to the electrical connector on the retarder valve

body (Figure 5–3).

• Insert the temperature sending unit into the retarder valve body (Figure 5–3).

Tighten the sending unit connector to 15–20 lb ft (22–27 N·m).

Figure 5–3. AT 500R External Connections

NOTE: On retarder units there are two coolers to connect. See Figure

5–3 for proper location of cooler connections. Tighten cooler fittings

on the primary cooler to 40–50 lb ft (54–68 N·m). Tighten cooler

fittings on the secondary cooler to 15–22 lb ft (20–30 N·m).

RETARDER VALVE BODY

TRANSMISSION “FROM COOLER” PORT

FROM PRIMARY COOLER

TRANSMISSION

“TO COOLER” PORT

WIRING HARNESS

CONNECTOR

TO PRIMARY COOLER

TO SECONDARY COOLER

CONNECTS TO

TRANSMISSION “MAIN” PRESSURE TAP

(OPPOSITE SIDE OF TRANSMISSION)

CONNECTS TO TRANSMISSION

“TO COOLER” PORT

TEMPERATURE

SENDING UNIT

L02889.01

Loading...

Loading...