31

5–4. COUPLING TO DRIVELINE

• Couple the driveline companion flange or universal joint yoke to the

transmission output flange or yoke.

• Use the bolts, nuts, and torque specified by the vehicle manufacturer.

5–5. INSTALLING VACUUM OR AIR MODULATOR CONTROL

• Make sure the original sealring has been removed from the modulator can or

from the counterbore of the transmission housing.

• Install the sealring onto the modulator. Coat the sealring with oil soluble

grease.

• Install the modulator control into the transmission housing. Seat the sealring

in the counterbore in the housing.

• Install the modulator retainer so that the convex side of the curved ends are

toward the transmission. Secure the retainer with a

5

⁄16-18 x

3

⁄4 inch bolt.

Tighten the bolt to 10–16 lb ft (19–22 N·m).

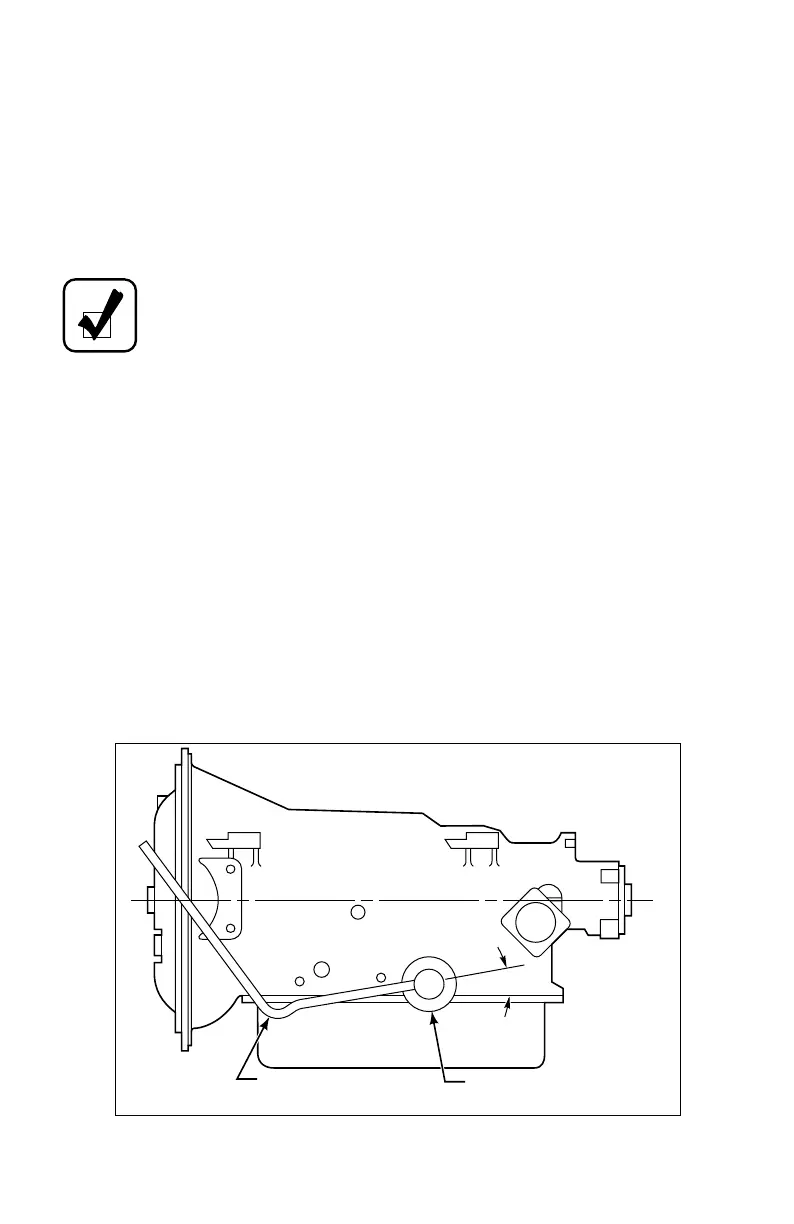

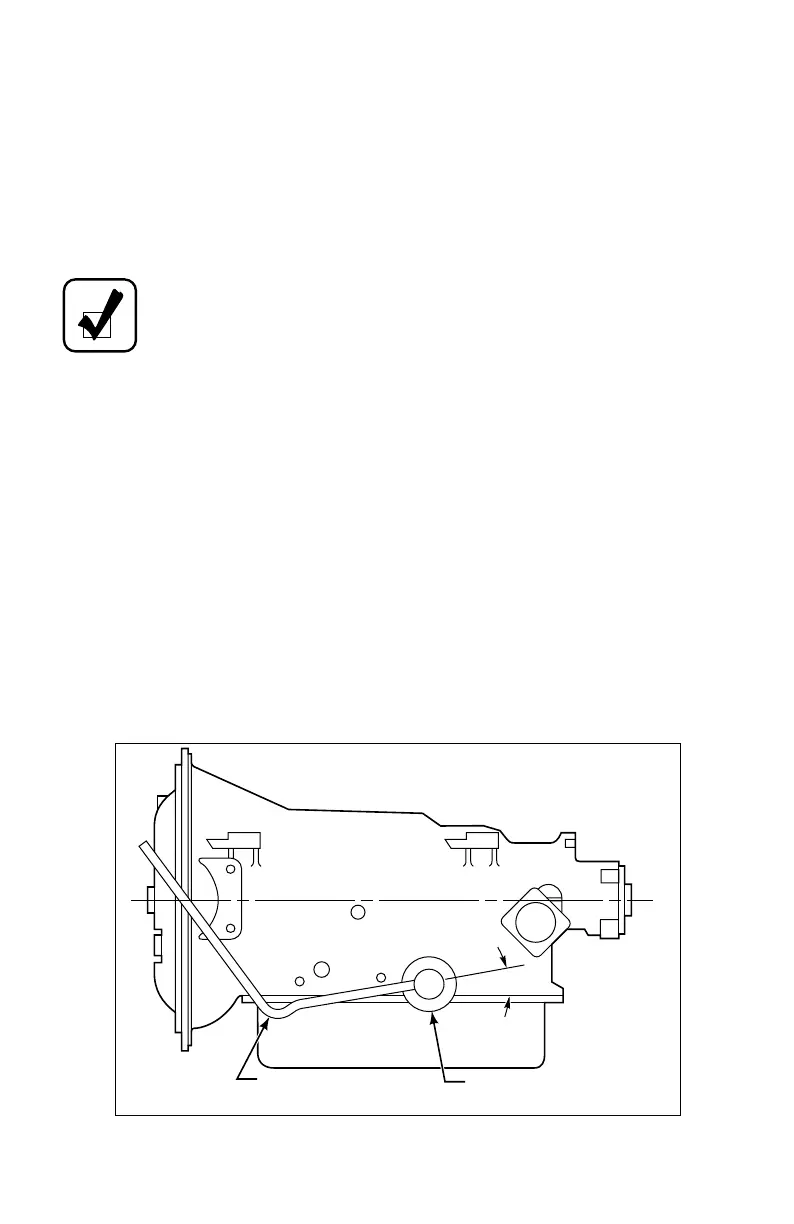

• Connect the vacuum or air line to the modulator. The tube connection at the

vacuum modulator should face toward the engine. The routing should be

approximately 10 degrees below horizontal and include a condensate trap

(goose neck) as shown in Figure 5–2.

Figure 5–2. Proper Relation of Vacuum Hose to Modulator Control

NOTE: There are 12V and 24V electric modulators available as of

June 1994. See SIL 27-TR-94.

CONDENSATE TRAP

VACUUM MODULATOR

10°

V03009

Loading...

Loading...