SVP INSTRUCTION MANUAL Page 9

SHAW-ALMEX INDUSTRIES LIMITED 49909-010

Jun 2017

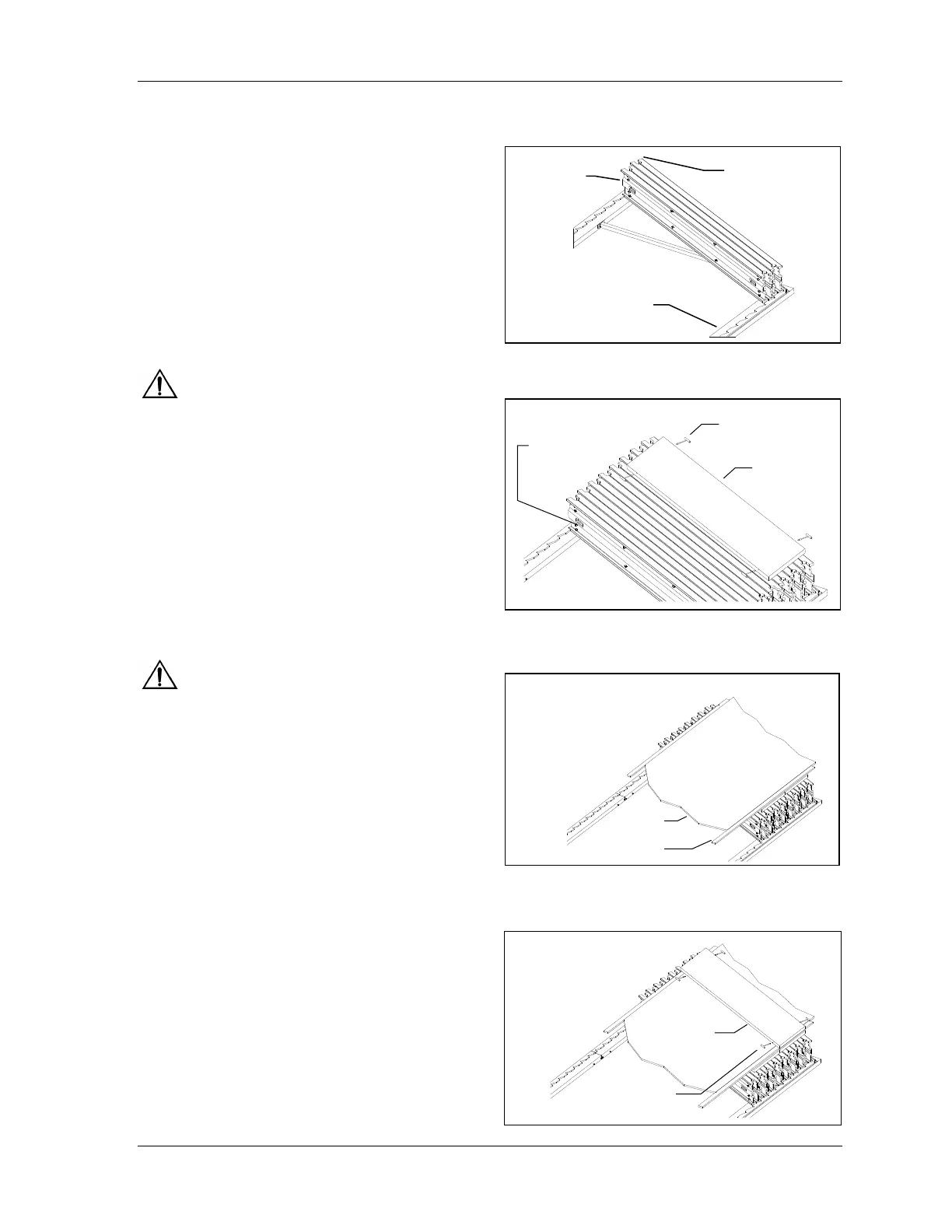

1. Remove idlers from the conveyor to provide space

for assembly of the vulcanizer. Use the set up

template and the General Arrangement drawing to

judge the distance.

2. With the ends of the conveyor belt laid back out of

the way, locate the template at the splice location.

The templates ensure the correct traverse bar

spacing and the joiner angles ensure the correct

bias angle. See Figure 4 Templates.

3. Position the traverse bars on the template. If the

end of the traverse bar is relieved for the tie bolt,

make sure the relief is on the top. See Figure 5

Traverse Bars.

Safety: Use safety slings for moving components

too heavy to be moved manually.

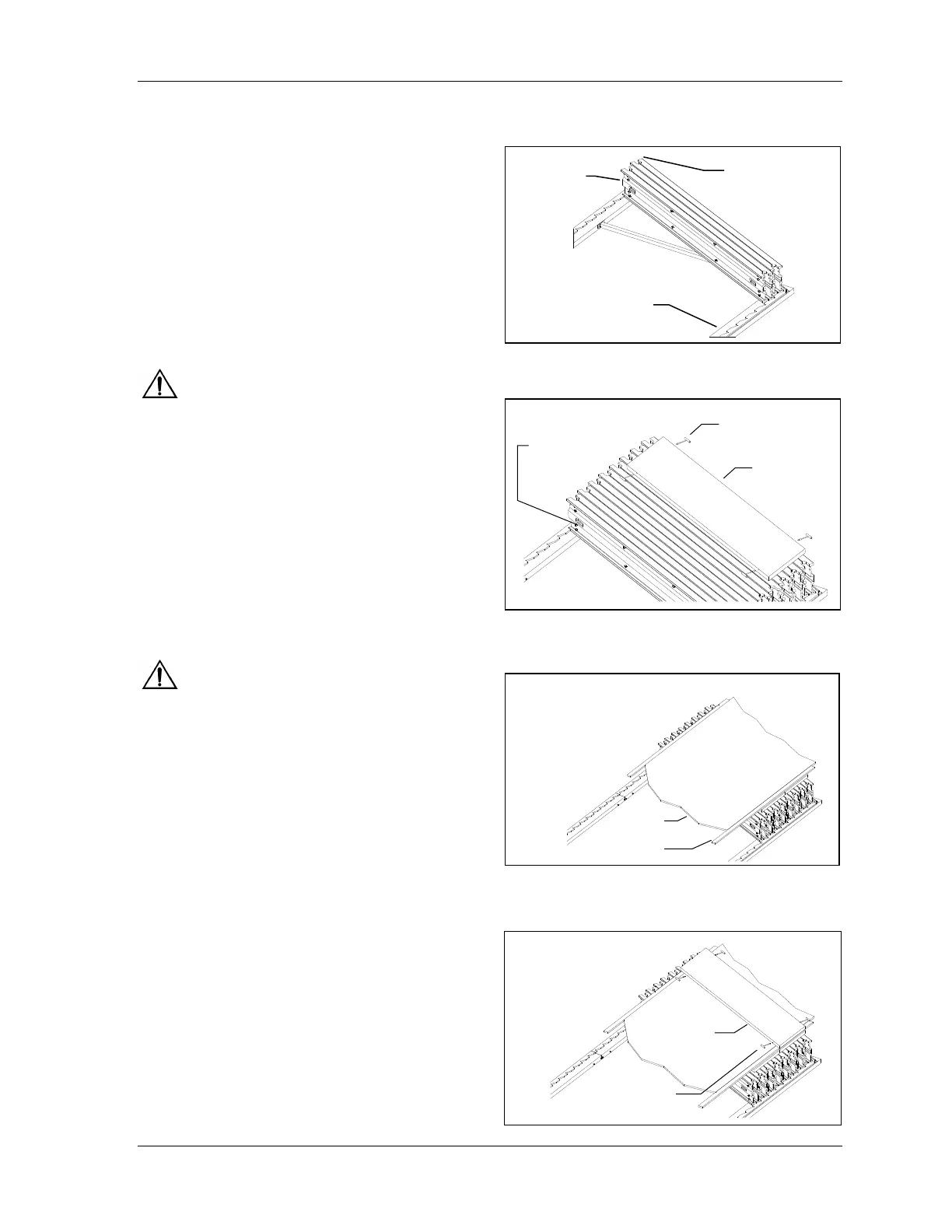

4. Install the lower restraining bars. With the gauge

pin removed from one end, slide the bar through

each traverse bar and install the gauge pin. Both

gauge pins should be approximately 3/4” (18 mm)

from the side of the outer traverse bars.

5. Install the platen carrying handles or hoist rings

into the threaded holes on the edge of the lower

platen hand tight. See Figure 6 Bottom Platen and

Handles.

6. Lift the platen onto the lower bars. Make sure the

platen is centered in both directions over the bars.

Safety: Do not use the platen handle to lift the

platen overhead.

7. Remove the platen handles because they will cause

cold spots on the platen.

8. If the orientation of the platens causes the electrical

and cooling fittings to be underneath the belt,

install the cooling hoses and platen cable now.

9. Prepare the splice on the bottom platen. It is good

practice to lay plywood or some other material on

the bottom platen while preparing the splice to

prevent damage to the platen surface.

Tip: A plywood deck can be built up around the platen

to increase the size of the worktable.

Caution: This unique platen requires support over its

entire area or permanent distortion of the platen may

occur. Fill any unused portion of the platen area with

scrap belting or shims the same thickness as the belting

being cured.

10. Install the cooling hoses on the bottom platens at

this time. It can be difficult to install the cooling

fittings after the edge irons and top platens are in

position.

Loading...

Loading...