Pipe dimensions and materials

Liquid pipeGas pipe

Ø9.52 mm (3/8")Ø15.88 mm (5/8")Pipe dimension

Flare - (3/8")Flare - (5/8")Connection

Copper quality SS-EN 12735-1 or

C1220T, JIS H3300

Material

0.8 mm1.0 mmMinimum material

thickness

Pipe connection

■

Perform pipe installation with the service valves (QM35,

QM36) closed.

■

L8 SPLIT

Remove the side panel on L8 SPLIT/L12 SPLIT during in-

stallation to facilitate access.

L12 SPLIT

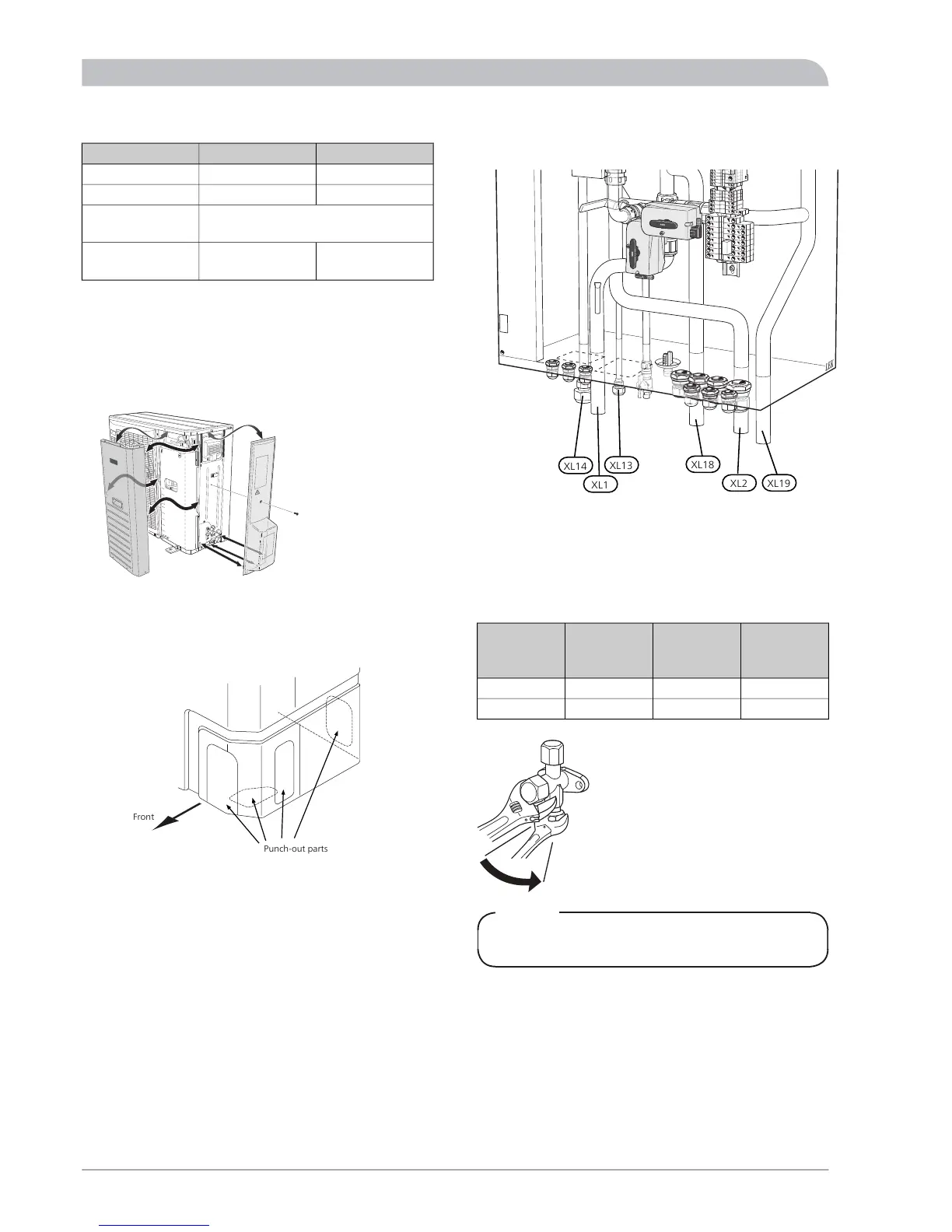

Remove a "punch-out" part from the outer panel on L8

SPLIT/L12 SPLIT, where the pipes are to be routed. The

image below, shows possible pipe outlets.

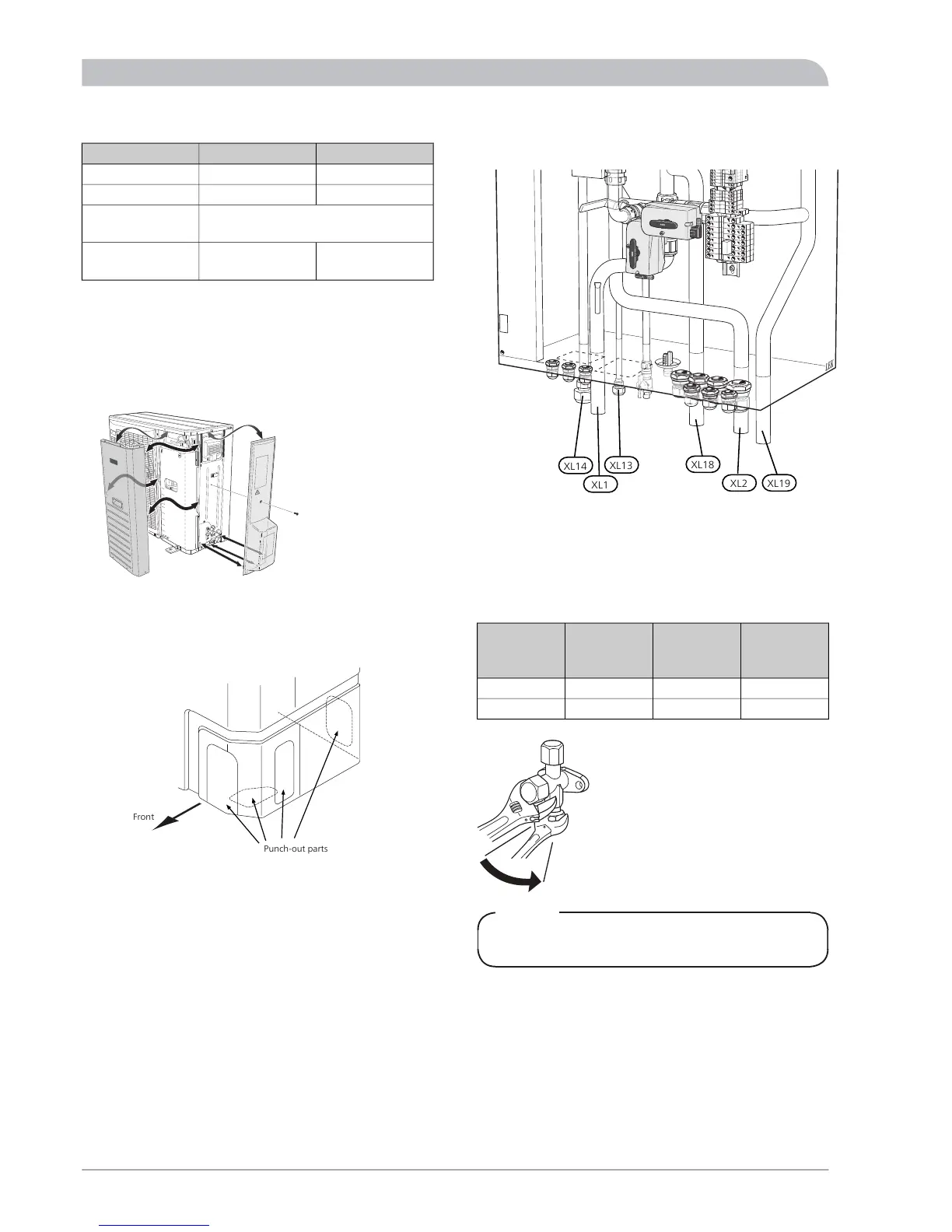

HM 8-12 SPLIT

The image below, shows possible pipe outlets.

■

Ensure that water or dirt does not enter the pipes.

■

Bend the pipes with as large a radius as possible (at least

R100~R150). Do not bend a pipe repeatedly. Use a

bending tool.

■

Connect the flare connector and tighten to the following

torque. Use the "Tightening angle" if a torque wrench

is not available.

Recommen-

ded tool

length (mm)

Tightening

angle (°)

Tightening

torque (Nm)

Outer diamet-

er, copper

pipe (mm)

20030~4534~42Ø9.52

30015~2068~82Ø15.88

NOTE

Gas shielding must be used when soldering.

SPLIT26

For the Installer

Pipe installation

Loading...

Loading...