Iftheconnectionleaks:

1. Undoconnectionandcheckpipefordamage.

2. Tighten the union nut hand-tight and retighten with

the open-ended spanner with 1/8 to 1/4 turn, as

the clamping ring is already in a clamping position.

Connect the unit to the heat source,

domestic water pipes and heating circuit

1. Install shut-off devices in the heating circuit.

2. Insert the vent at the highest point of the heat

source and the heating circuit.

3. Recommendation: Fit a dirt lter with mesh size

0.9 mm onto the heat source inlet.

4. Connectthedomestichotwatertankaccordingto

the local regulations.

5. Recommendation: To balance out pressure

uctuations and water hammers and avoid

unnecessary loss of water, install an expansion

vesselwiththrough-owtting.

6. Ensure that the operating overpressures

( “Technical data/Scope of supply” on page

24) are not exceeded. Install pressure reducer

if necessary.

6.4 Connect the electrical cables

ATTENTION

Irreparable damage to the compressor due to wrong

rotatingeld!

► Ensurethat there is aclockwise rotating eld for

the compressor load infeed.

Basic information on the electrical connection

NOTE

Ensure that the unit is supplied with electricity

atalltimes.Afterworkinginsidetheunitand

attaching the unit panelling, switch the power

supplybackonimmediately.

● The specications of the local power supply

company may apply to electrical connections.

● Fit the power supply for the heat pump with an all-

pole miniature circuit-breaker with at least 3 mm

contact spacing (IEC 60947-2).

● Note the level of the tripping current

( “Technical data/Scope of supply” on page

24).

● Comply with the electromagnetic compatibility

regulations (EMC regulations).

–

Lay the control/sensor cables and unit supply

cablesufcientlyfarapart(>100mm).

–

Lay unshielded power supply cables and

shieldedcables(LINbuscable)withsufcient

distance between them.

● Do not lengthen the patch cable and LIN bus

cable. LIN bus cables up to 30 m long can be

used.

Pullinthecablesandconductorsandmake

the connections

1. Strip the sheathing of electrical cables before

laying in the cable duct of the control box.

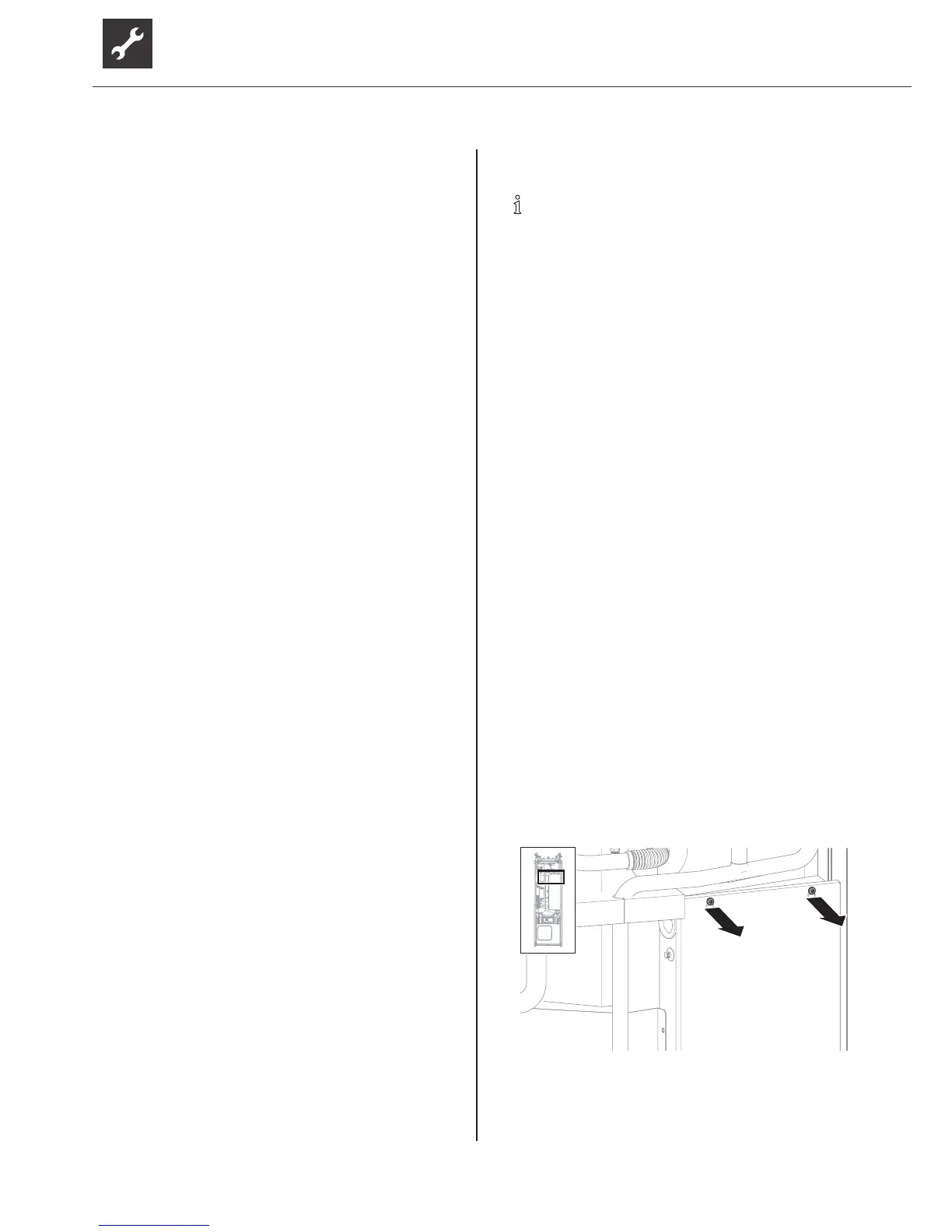

2. Open electrical switchbox:

–

Undo 2 screws at the top of the cover panel of

the electrical control box.

–

Unhookcoverpanel.

Loading...

Loading...