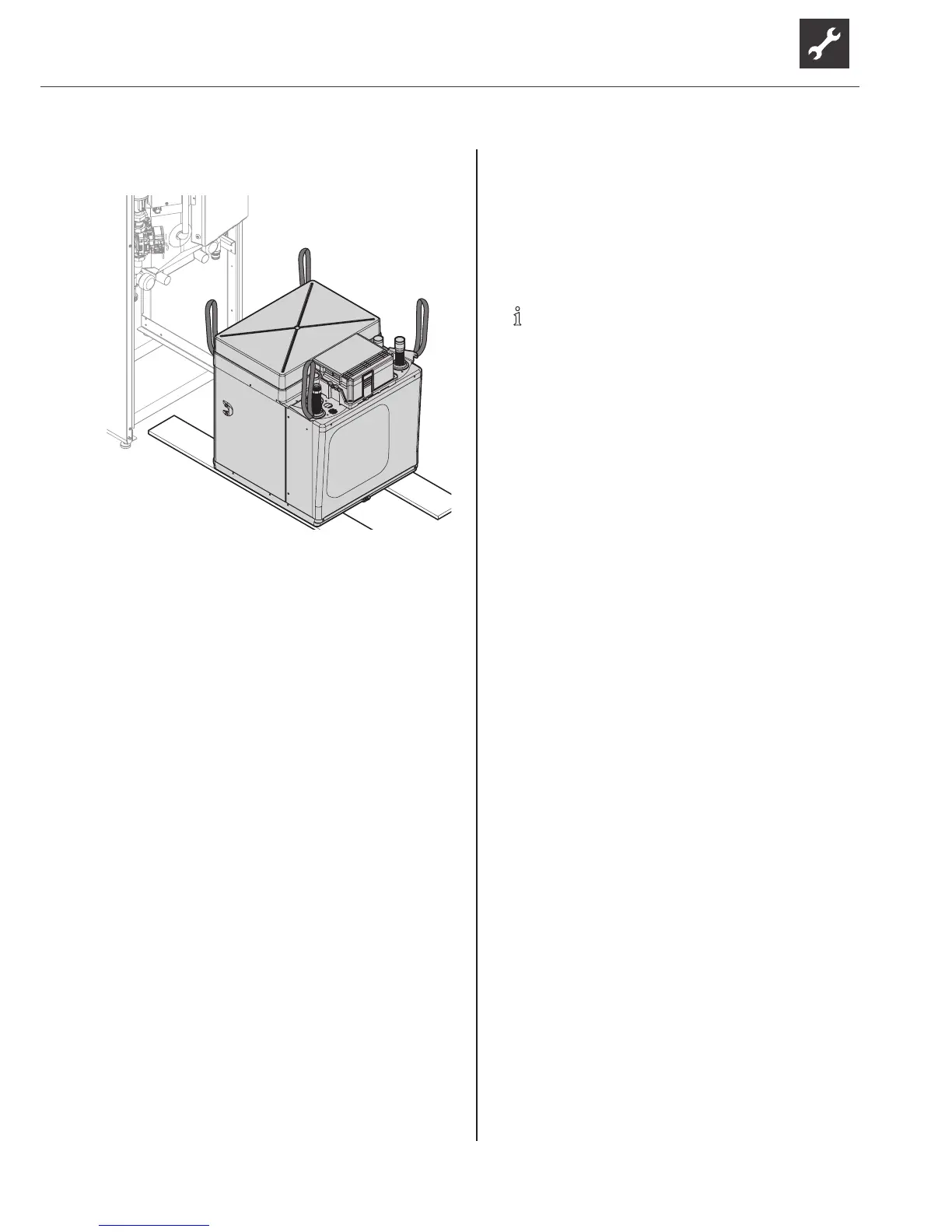

15. Pull out the module box completely and place it on

the boards.

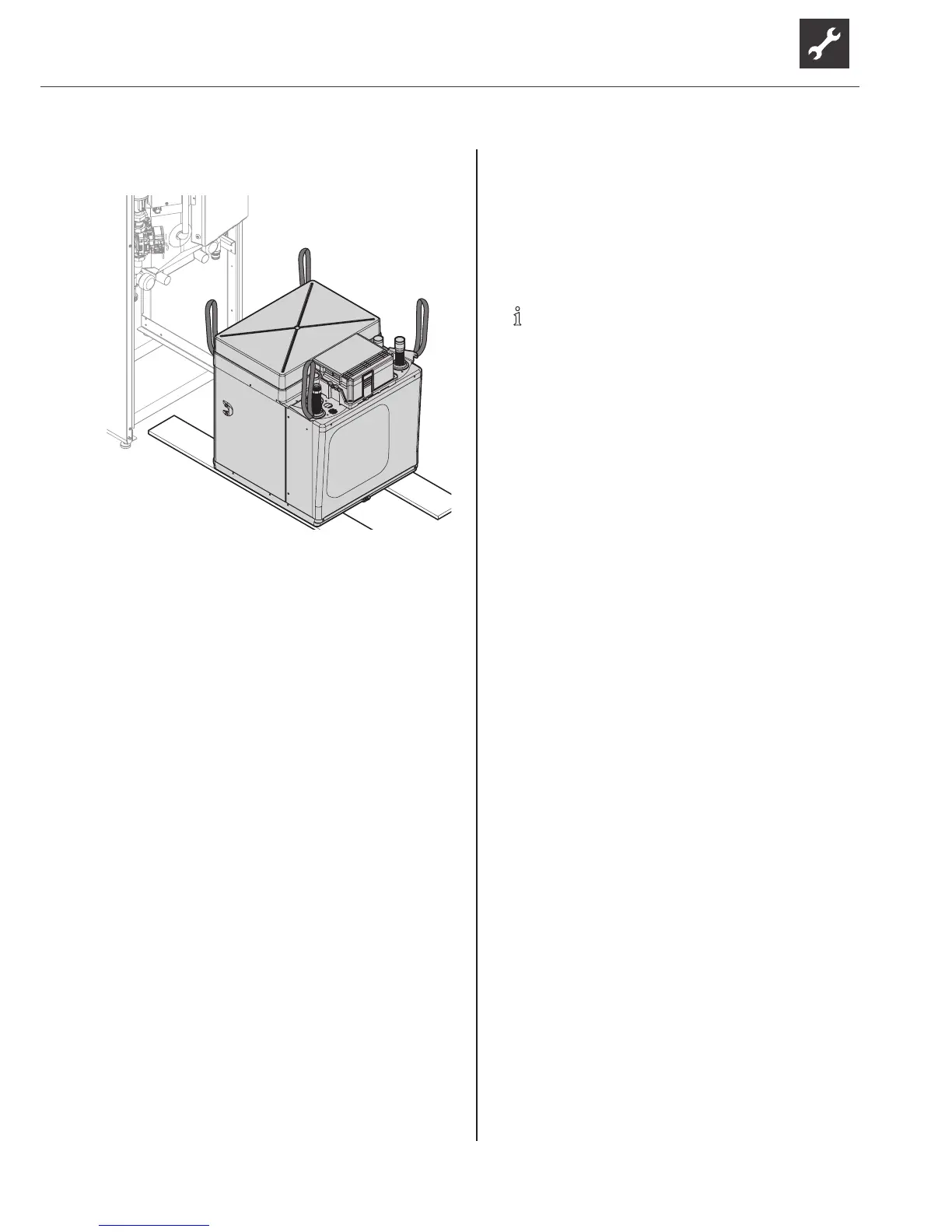

6.2 Installing the module box

1. Place the module box carefully in the bottom in the

heating station and slowly and carefully push it in.

–

At the same time, lift and hold the nut on the

heatingow.

–

Ensure that none of the pipes are damaged.

2. Attach the two side retaining screws.

3. Connect the heating ow and hydraulic

connections. At the same time, replace O-rings

on the heat pump connections (separatepack

included).

4. Perform pressure test and insulate pipes with the

enclosed insulation hoses (separatepack).

5. Connect the electrical connections.

–

Plug in 2 white connectors at the bottom of

the electrical control cabinet. Ensure that the

connectors move easily and the lugs latch into

position.

–

Plugintheblackrectangularconnectoratthe

top of the module box.

6.3 Install the hydraulic connections

ATTENTION

Damage to the copper pipes due to unacceptable

loading!

► Secure all connections against twisting.

NOTE

The heat source can be connected from the

top, right or left.

The heat source system has been installed in

accordance with the specications ( planning

& design manual, dimensioned diagrams,

installation plans).

Cross-sections and lengths of the pipes for the

heating circuit and heat source are dimensioned

adequately.

The free pressure of the circulation pumps

produces at least the minimum throughput

required for the unit type ( “Technical data/

Scope of supply” on page 24).

The cables for the heat source and the heating

arexedtothewallorceilingviaaxedpoint.

Installthecompressionttingsandball

valves

ATTENTION

Leaks or fracture of the union nut due to excessive

force!

► Tighten the union nut only as far as described

here.

1. Check pipe ends for scratches, dirt and

deformation.

2. Checkproperpositionoftheclampingringonthe

tting.

3. Push the pipe through the clamping ring up to the

limitstopinthetting.

4. Tighten the union nut hand-tight and attach

waterproofmarking.

5. Tighten union nut with 3/4 rotation.

6. Checkconnectionforleaks.

Loading...

Loading...