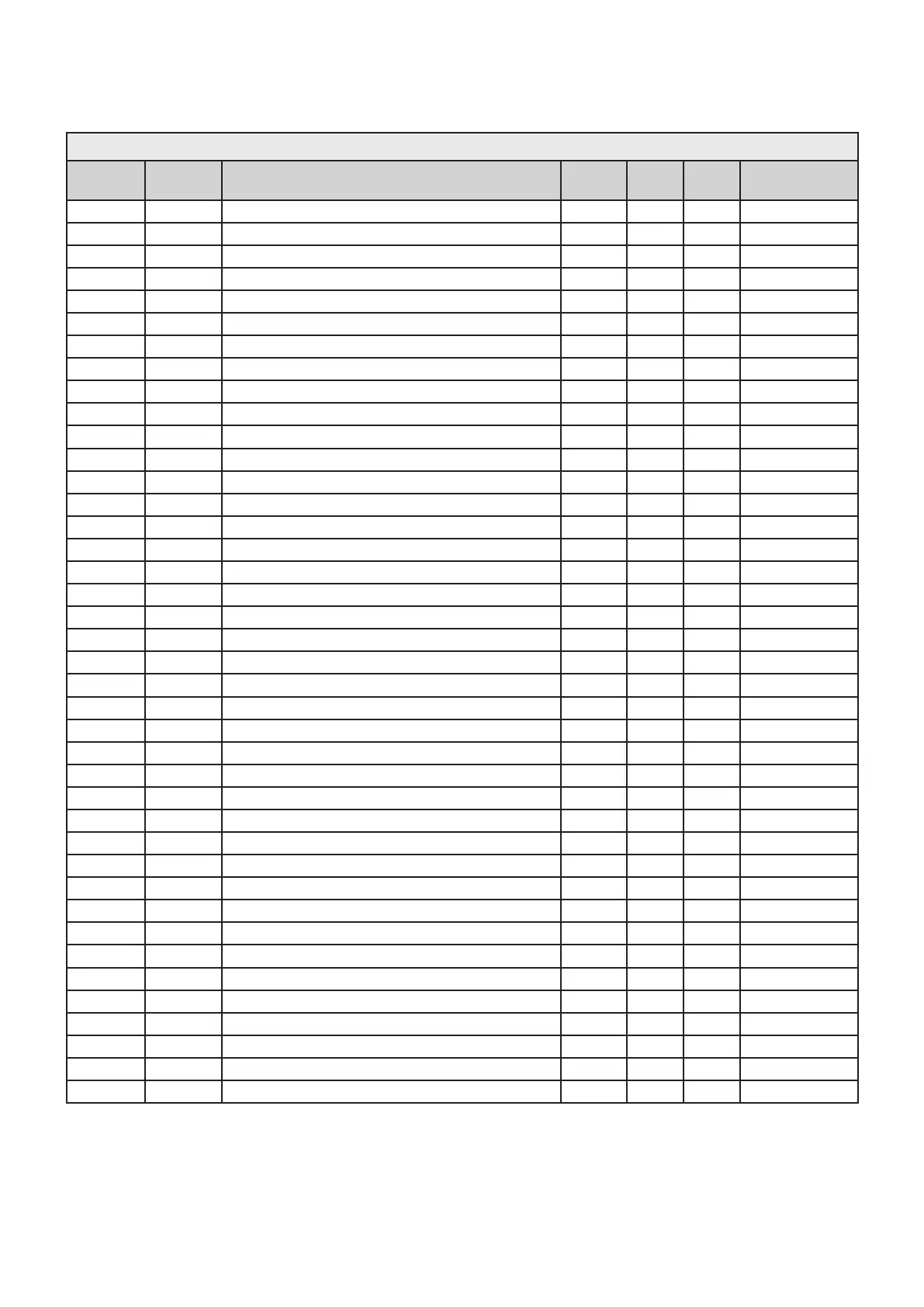

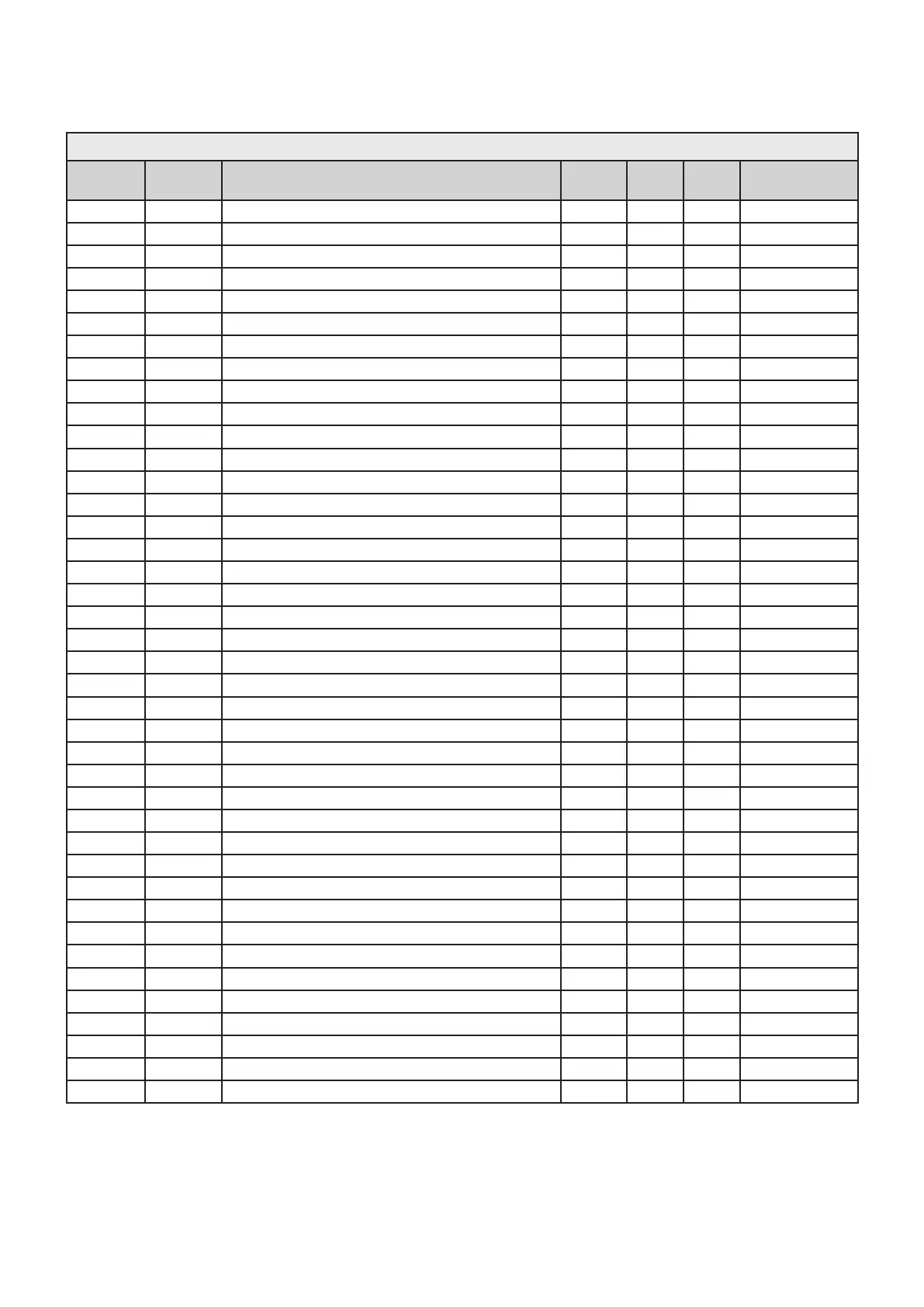

50

Inspections and maintenance

BCM parameters

Code Symb. Description Unit Min Max Factory settings

803 Srv Services Enabled 16 27 19

483 rP Gen: Temp. Max Dierential °K 0,0 50,0 25

34 HY Burner Hysteresis °K 5,0 20,0 5,0

31 HL CH#1: Minimum Setpoint °C 20,0 40,0 35,0

39 HH CH#1: Maximum Setpoint °C 45,0 85,0 85,0

799 AC Input 0/10V 0 3 1

376 DI1 Programmable Input #1 0 2 3

322 Po Pump Post-circulation min. 1 10 5

341 PL Pump Minimum Control V 0 10 3

313 Pr Pump Maximum Control V 0 10 10

792 CHP CH: Max Modulation % 0 100 100

611 POT Gen: Err. Max. Parallel °K 0 30 5

612 POL Gen: Mod. Max. Parallel % 0 100 0

650 dL

DHW: Minimum Setpoint °C 25,0 45,0 35,0

385 dH DHW: Maximum Setpoint 50,0 65,0 65,0

360 dt Storage tank adjustment 0 15 0

656 drT DHW: Temp. Request Dierential °K -20 20 4

657 drH DHW: Request Temp. Hysteresis °K 1 20 8

310 DpT DHW Pump: Postcirc. sec. 5 600 60

660 dbT DHW: Temp. Boiler Maximum °C 50,0 85,0 75,0

48 ChSet CH#1: Setpoint °C 20,0

85,0

85,0

64 ChPO1 CH#1: Parallel Supply 0 1 0

346 FL Minimum Modulation % 0

100,0

25,0

600 mB Burners: Min. Inserted 1 8 1

616 BSt Gen: Insertion Time sec. 30 900 120

613 BRt Gen: Removal Time sec. 30 900 120

336 HS Temperature Gradient °C/min 1 30 5

353 HP CH PID: Proportional °K 0 50 25

354 HI CH PID: Integrative °K 0 50 12

478 Hd CH PID: Derivative °K 0 50 0

816 MI ModBus Address 1 127 1

817 MT Timeout Modbus sec. 0 240 30

896 TU °Fahrenheit 0 1 0

309 St Application Code

0 1 0

368 VA1 Programmable Relay #1 0 1 0

369 VA2 Programmable Relay #2 0 1 1

771 PS Water Pressure Sensor 0 1 0

768 LG Min. Gas Pressure Sens. 0 1 0

793 COC Chimney Obstruction Sens. 0 2 0

622 FS Minimum Flow Sensor 0 1 0

Loading...

Loading...