6 • Section 3 — Safety

into consideration general material shape, protrusions,

and attached limbs.

Chipper Personnel Safety Devices

Danger

Death or serious injury will result from careless or

improper use of the unit. Do not operate the unit

without proper training.

All personnel using this chipper must be trained and

qualied in all aspects of the operations, maintenance,

repair, and safety procedures dened in this manual

prior to conducting any operations or procedures. All

maintenance personnel and operators shall ensure the

proper operation of each safety device prior to starting

the engine or operating the chipper. Contact Altec Envi-

ronmental Products for replacement parts.

Warning

Death or serious injury can result when operating

this unit. Safety devices are not a substitution for

proper operation. Read the entire manual and all

safety decals and placards.

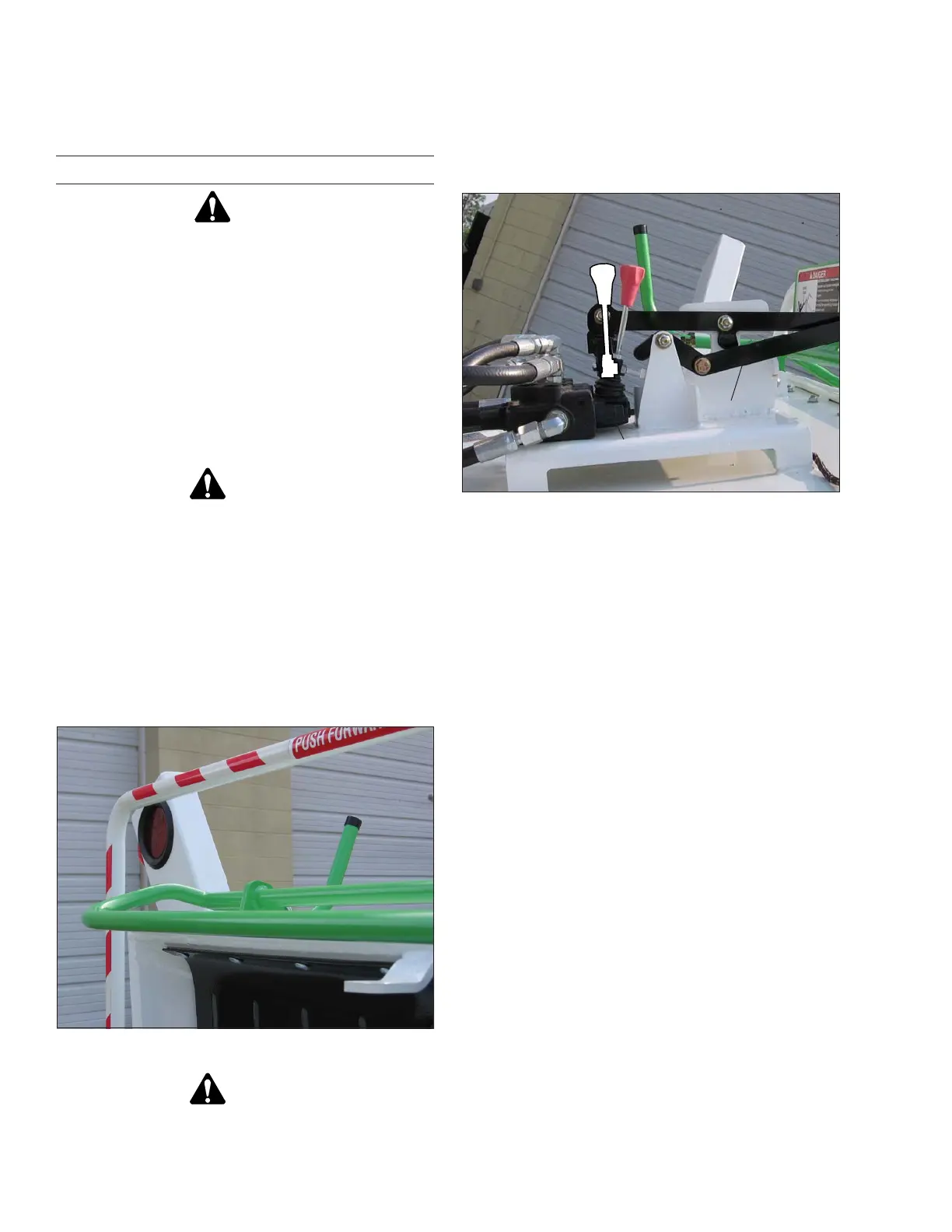

Panic Bar Assembly

In the event of an unforeseen situation the panic bar

(refer to Figures 3.1 and 3.2) can be activated by pulling

down on bar A or by pulling or pushing bar B towards the

rear of the chipper. This action will stop all movement of

the feed roller.

Figure 3.1 — Panic Bar Assembly

Warning

Death or serious injury can result from unexpected

roller movement. Feed rollers begin movement as

soon as the valve handle is activated. Make sure all

operators are advised prior to your actions and that

the infeed chute is clear of all personnel and tools

before reactivation of the feed system.

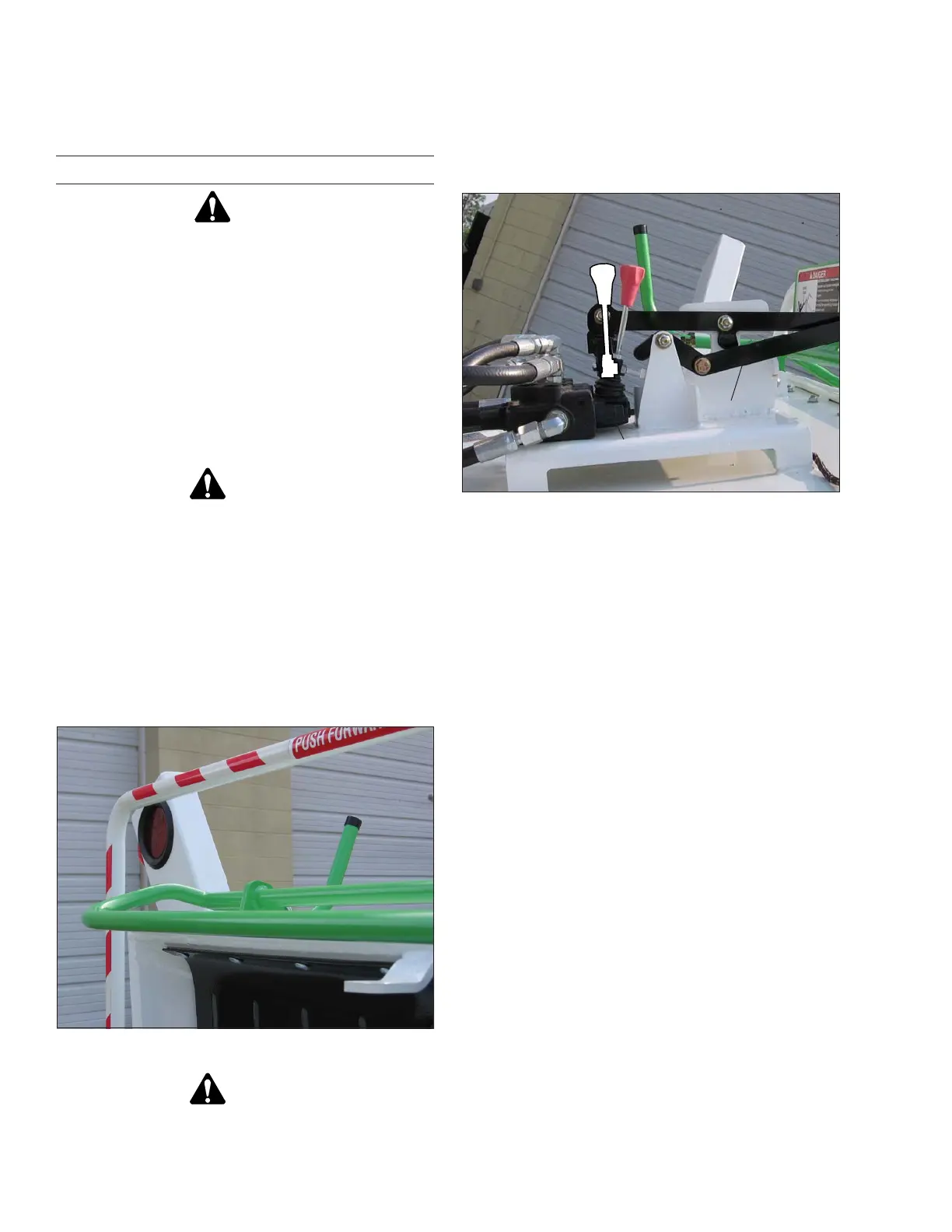

Figure 3.2 — Valve and Bar Linkage

The panic bar assembly consists of two bars (A and B),

the hydraulic valve and the bar linkage. When you pull

down on bar A or push towards the rear of the chipper

on bar B, the bar connecting linkage activates the handle

on the valve. This action stops all movement of the feed

rollers. To continue operation you must manually reset

the handle on the valve to the Run position.

1. Test the panic bar assembly daily and whenever new

personnel are assigned to the chipper.

2. After completing all appropriate safety and operational

checks and with no material in the infeed chute, pull

or push the feed bar to activate the feed roller in the

forward or reverse direction. Visually verify the rota-

tion of the feed roller.

3. Push down on bar A or move bar B.

4. Feed roller movement must stop.

5. If feed rollers do not stop, repair as necessary prior

to operating the chipper.

Chip Curtain

The kickback curtain (refer to Figure 3.3) stops or deects

chips and small debris from leaving the infeed chute

area. This also helps in decreasing the amount of clean

up around the chipper.

Run

Stop

Valve

Bar Linkage

A

B

Loading...

Loading...