54 • Section 7 — Maintenance

material will cause the drum rpm to reduce. In the event

that the rpm drop below 2,000 rpm, the control module will

automatically send a signal to the EFC valve and reverse

the rotation of the feed wheel. This will remove the fed

material from the cutting drum and allow the system to

regain speed. During this time, the EFC valve is in the

neutral state. The system will not automatically resume

forward feed until the drum rpm have recovered. This

event occurs quickly and can last less than a second.

Advance System Recovery

Advance system recovery is a secondary security mea-

sure designed to ensure that the wood fed is controlled.

In the event that the EFC cannot reverse the fed material

due to the wood being too short, the advance system

recovery prevents the wood from being pushed into the

cutting mechanism as the feed wheel descends. It also

monitors the drum rpm disabling the fed material from

dropping the drum rpm to the point where the system would

shut down the engine. This ensures longer component

life and more effective performance. The specic compo-

nents involved in the system are the control module, lift

cylinder, holding valve, and the magnetic speed sensor.

Using the magnetic pickup, the control module monitors

the drum rpm. When feeding wood forward, the material

will cause the drum rpm to reduce. In the event that the

fed material cannot be reversed because it is too short, the

feed wheel will advance it forward as it descends about

the pivot point. If the rpm drop below 1,300, the control

module will automatically send a signal to the holding

valve and block the ow of oil from the lift cylinder. This

will prevent the cylinder from descending. The system

will not automatically resume the descend until the drum

rpm have recovered. This event occurs quickly and can

last less than a second.

While the EFC valve will only allow ow to the motor in a

specic rpm range, the lift cylinder can be used any time

that the engine is running. The feed roller assembly can

be lifted up allowing brush or logs to be tethered through,

or lowered down putting pressure and compressing the

fed material. It is important to note that in the descend

of the feed wheel will have a timed delay in the range

between 200 rpm and 1,300 rpm. The system will allow

for upward motion, but will not allow downward motion

until several seconds have passed.

Warning

Death, serious injury, or property damage can result

when attempting to access moving components.

Make sure components have come to a complete

stop before performing inspection or maintenance.

During any point in operation, the panic bar can be pulled

stopping all hydraulic ow to the system. This will divert

all pump ow directly to tank rendering all successive

functions (feed motor, lift cylinder, etc.) disabled. The

panic bar solenoid must be reset in order to resume

system operation.

Troubleshooting

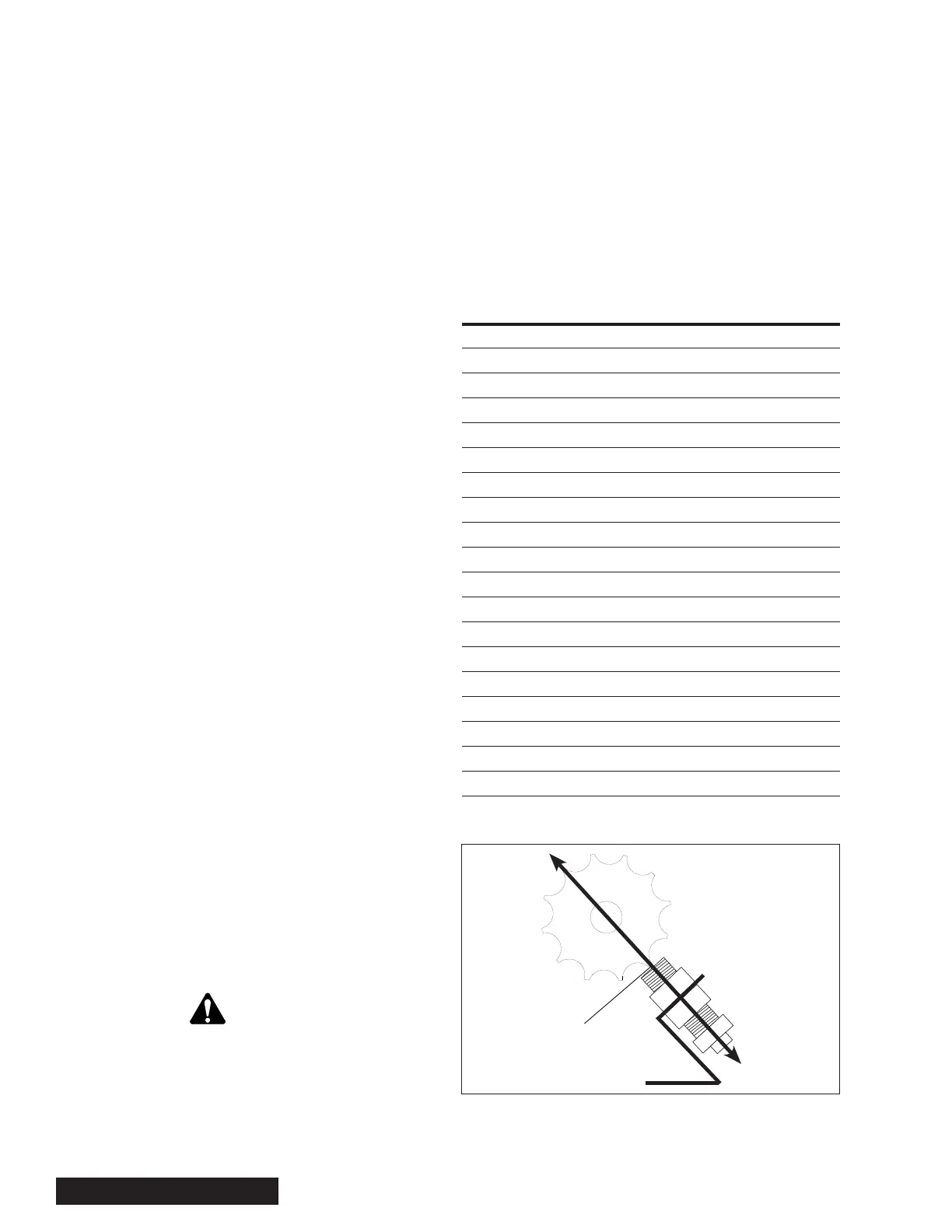

Refer to Figure 7.7 for troubleshooting information.

Drum Magnetic Pickup

Speed (rpm) Frequency (Hz)

500 167

600 200

700 233

800 267

900 300

1,000 333

1,100 367

1,200 400

1,300 433

1,400 467

1,500 500

1,600 533

1,700 567

1,800 600

1,900 633

2,000 667

2,100 700

2,200 733

2,300 767

Figure 7.8 — Frequency to rpm Conversion

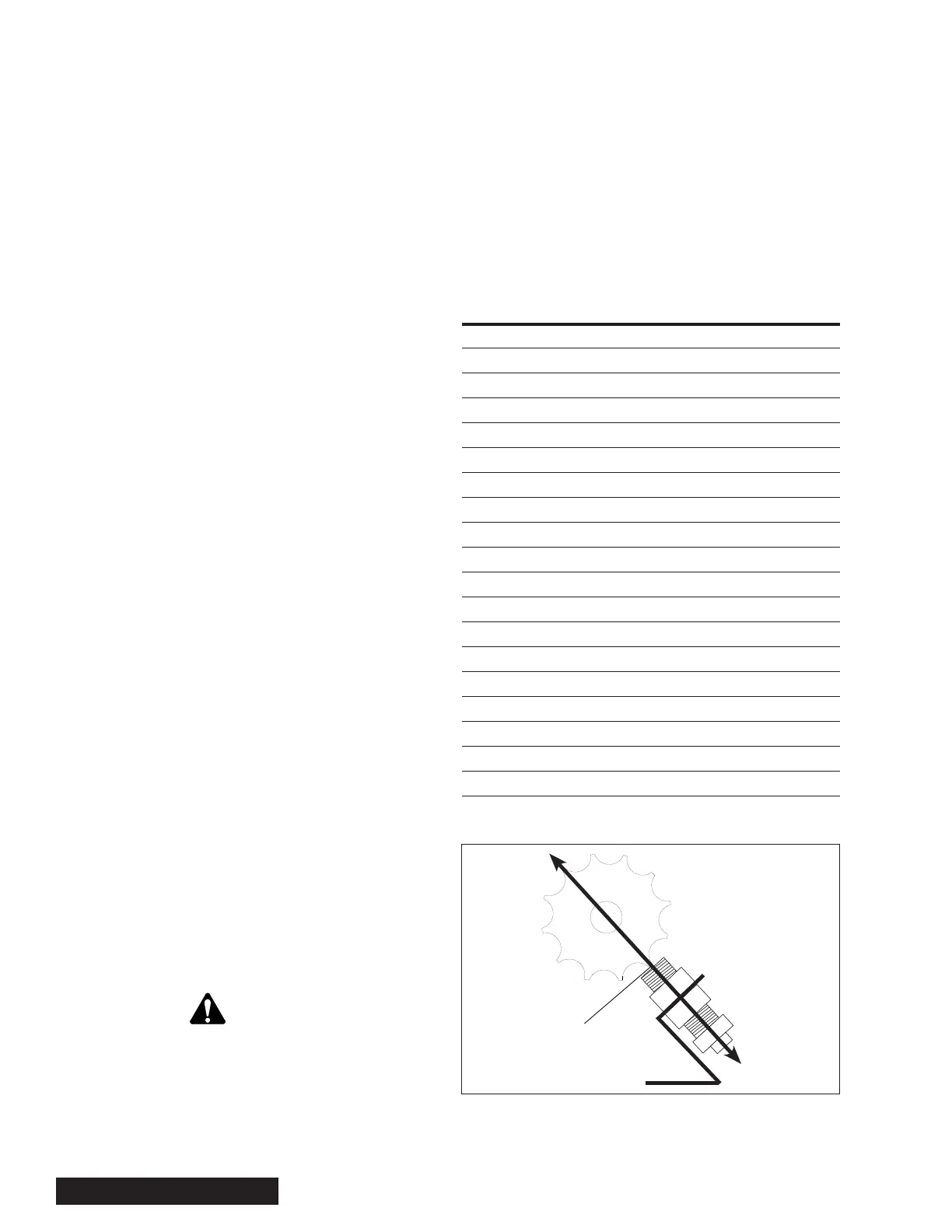

Figure 7.9 — Magnetic Sensor Pickup

C

Measure

Gap Here

Loading...

Loading...