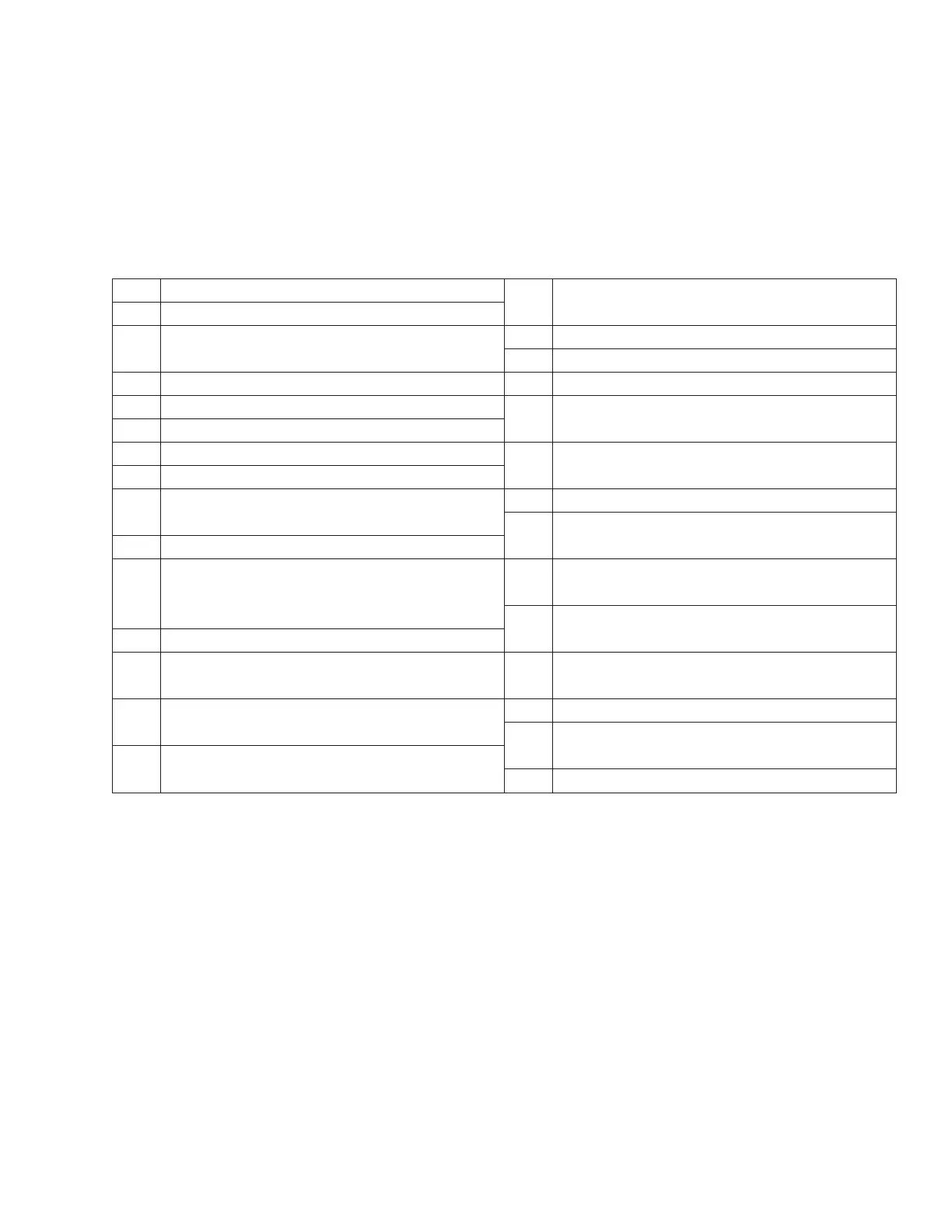

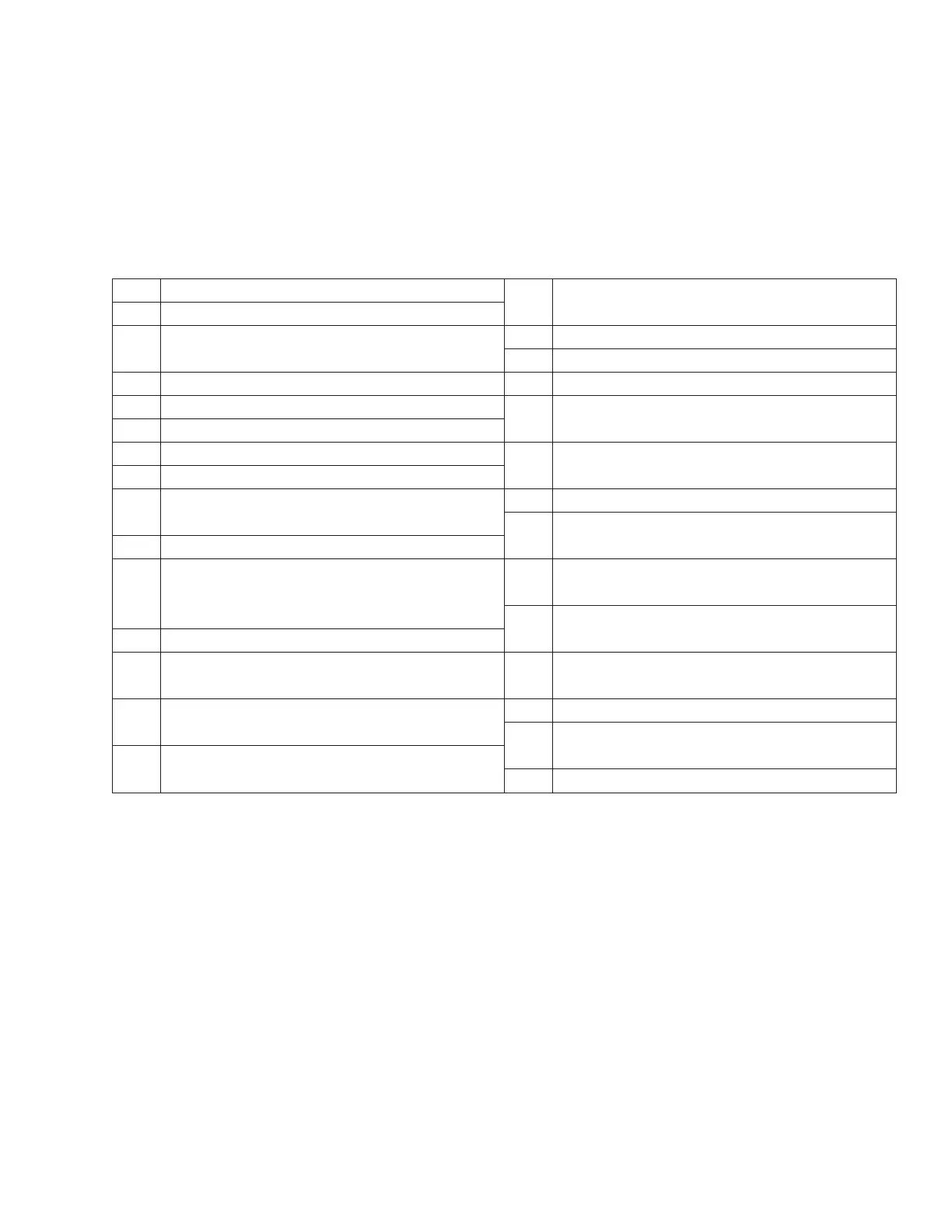

Appendix — Daily Preoperational Checklist

Daily Preoperational Checklist

VIN No. _________________________ Location ___________________________ Date __________________

Model Number ___________________________ Date of Manufacture __________________________________

Hours Meter _________________________ Inspector _______________________________________________

Symbols

/O = Okay or completed C = Corrected by inspector R = Repair or replacement required

U = Unsafe to operate N/A = Not applicable

Chip curtain is properly fastened and in good repair

Rotation indicator is clear of debris and fully visible

Disc/drum cover padlock is in place and key is in

responsible party’s possession

Disc/drum hood switch is working properly

Inspect safety tow chains for wear or damage

Check engine fuel, coolant, and oil levels (refer to EOM)

Checktheengineairlter(refertoEOM)

Check clutch handle free play

Checkradiatornsandensurefreepassageofair

through the radiator

All cap screws and nuts are tight and secure

Inspect anvil to make sure all attachment and

adjustment cap screws are secure and anvil edge

is in good condition

Check all controls for free and proper operation

Inspect the chipper frame and structure for any bent,

broken, cracked, missing, or loose parts

Check all guards to make sure they are undamaged,

in place, and properly secured

All decals must be in place and legible prior to

operating the chipper

Hydraulicuidlevelmustbewithin2”to3”(5.08to

7.62cm)oftopofthetankwhentheuidiscold

Lubricate cutter and feed roll bearings

Inspect and operate panic bar

Inspect for hydraulic leaks

Check cutting blades to make sure all attachment cap

screws are tight and blades are in good condition

Inspect discharge chute to determine if it is clear,

properly positioned, and secure

Check feed roller for debris

Check the transition area for debris that could lock

the drum or disc during start up

Make sure the safety devices are properly installed

and functioning properly

Make sure the feed table is in place and secure for

both operation and travel

No loose tools or materials on the chipper or on the

infeed chute

Wheelsandtiresaresecureandproperlyinated

Make sure a complete AEP Operator’s Manual is

available for all operators to review

Comments __________________________________________________________________________________

___________________________________________________________________________________________

Loading...

Loading...