Section 7 — Maintenance • 43

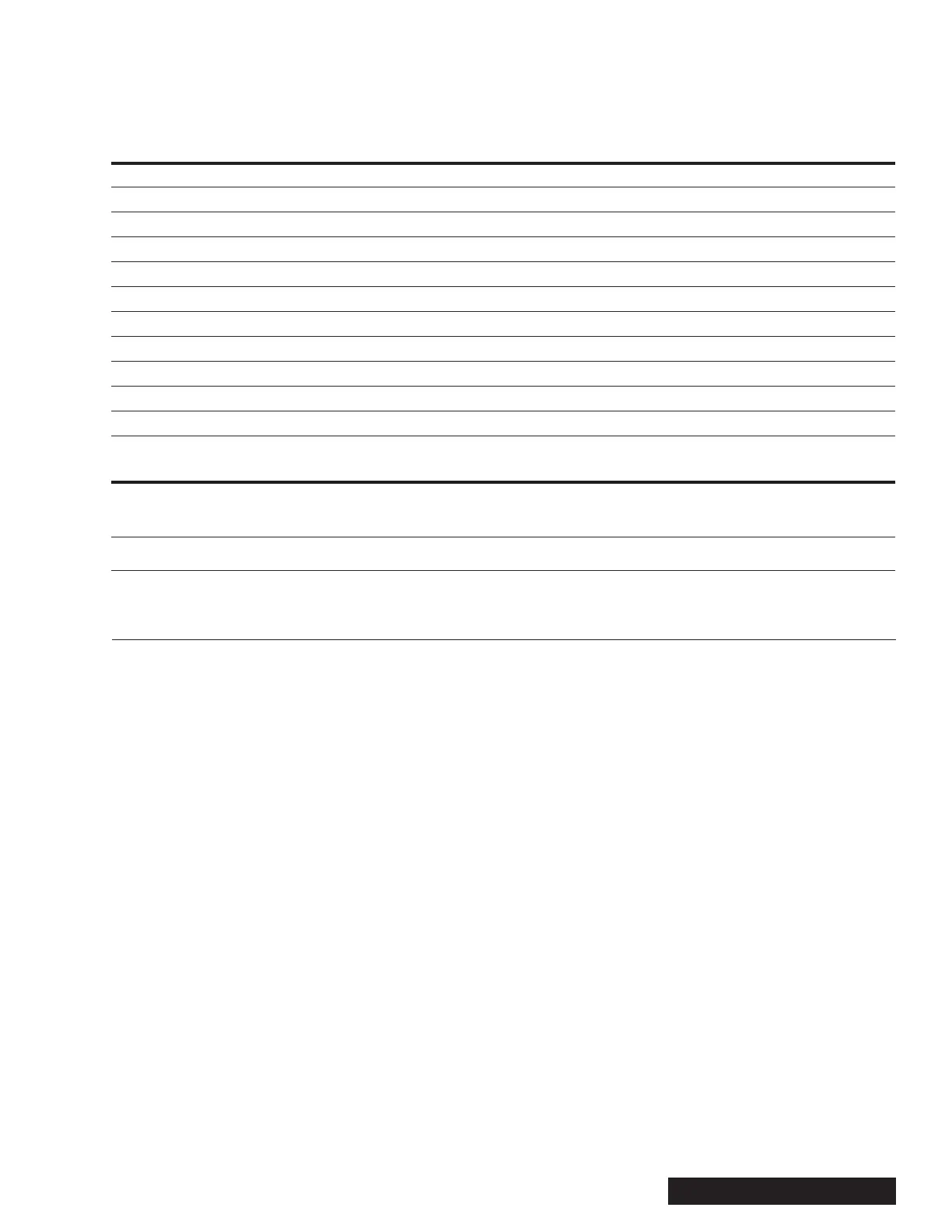

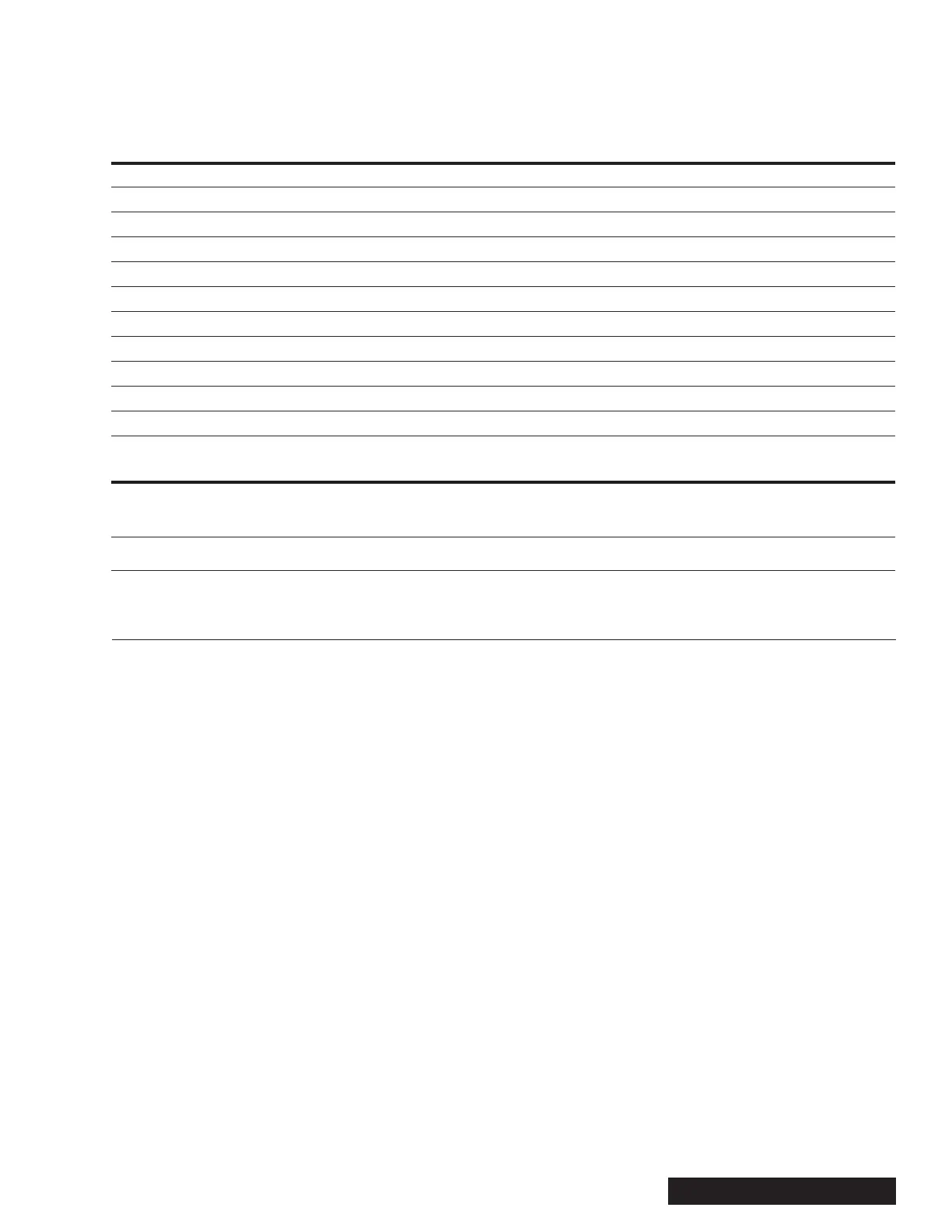

Lubrication Chart

10 Hours 50 Hours 200 Hours 1,000 Hours

Component Lubricant Applicator Daily Weekly Monthly Yearly

Cutter bearings A Grease gun •

Feed roll bearings A Grease gun •

Slide box A Grease gun •

Chute rotation A Grease gun •

Hinges, friction points B, C Spray •

Linkages B, C Spray •

Axle bearings A Grease gun Refer to axle owners manual

Jack A Grease gun •

Hydraulic oil ISO 46 •

PTO As required As required by PTO manufacturer

Engine As required As required by engine oil manufacturer

Letter Lubricant

A Use a premium grade, high temperature, lithium based grease. Some suggested greases include:

Mobile Mobilith AW 2, Shell, Alvaina Grease 2, Texaco 1939 Premium RB, Amoco Ryko Premium Grease.

B General purpose spray lubricant

C Spray lubricant that penetrates and adheres with good water resistance, is unaffected by temperature

extremes and has extreme pressure properties. Anti-seize compound with extreme pressure lubrication

that prevents seizure, corrosion, rust, and galvanic pitting.

Bearings

Spherical roller bearings are used on the cutter head and

feed roll assemblies. They require periodic lubrication

with a chassis lubricant.

It is very important to grease this type of bearing regu-

larly. If they are not greased properly, the usable life of

the bearing will be greatly reduced.

Remove any exposed grease from the bearing. Grease

each bearing daily with three or four pumps with a stan-

dard grease gun.

Slide Box

Clean exposed existing grease from the outside areas

of the way surfaces. Pump grease in all four ways until

new grease is observed.

Chute Rotation

Clean exposed existing grease from the outside areas of

the chute rotation area. Pump grease in all four grease

ttings until new grease is observed.

Hinge and Friction Points

Chipper operation and longevity can be improved by

keeping all hinges and friction points lubricated. Remove

all dirt, corrosion, or foreign matter. Lubricate with ap-

propriate applicator.

Axle Bearings

Standard axles on Altec Environmental Products, LLC

chippers have the UltruLube feature. This feature ushes

and lubricates both the inner and outer wheel bearings.

If your axle is equipped with the UltruLube feature, the

bearings can be periodically repacked and lubricated

without removing the hubs.

The procedure is as follows.

1. Remove the rubber plug from the end of the grease

cap.

2. Place a standard grease gun onto the grease tting

located in the end of the spindle. Make sure the

grease gun is fully engaged on the tting.

Loading...

Loading...