Section 5 — Clearing Feed System and Discharge Chute • 31

Section 5 — Clearing Feed System and Discharge Chute

Feed System

Warning

Death or serious injury can result if proper feed roller

clearing procedures are not followed. Only person-

nel that have been properly trained, understand the

dangers, and are authorized by the employer may

perform this operation.

Caution

Injury can result from being pinched or trapped be-

tween moving components. Keep hands clear.

Never attempt to pry open the feed rollers. Rollers must

only be opened using either the lift cylinder or the Altec

Environmental Products supplied jack.

Always be aware of pinch points during the lifting opera-

tion. These dangerous pinch points are changing during

the lifting operation. Never place any part of your body

between the feed rollers.

Extreme care must be taken when removing material or

performing service in the feed roller area.

Never place any part of the body into the feed roller area.

Use a stick or other nonmetallic object to clear this area

of debris.

Extreme care must be taken when removing material or

performing service in the transition chute area. Before

beginning any procedure make sure all movement of the

engine, disc, and feed roller have come to a complete

stop. Remove keys from the ignition and place in pocket.

Complete LOTO procedures.

Always make sure the feed roller assembly is secure

before attempting maintenance in the feed roller/transi-

tion area.

Never reach into or place any part of the body into the

transition chute.

Always use appropriate tools to remove jammed materi-

als. Never reach into the infeed chute.

In the event of material jammed between the feed rollers

and the disc, attempt the following actions before attempt-

ing the mechanical actions contained in this section.

1. Push forward on the control bar to attempt to reverse

the material backward.

2. With the drum at operational speed, attempt to load

another log into the feed rollers. This action may

advance the jammed material.

3. With the drum at operational speed, attempt to load

brush on the top of the jammed material. This action

may advance the jammed material.

4. If equipped with a lift cylinder, raising or lowering the

cylinder may advance the material.

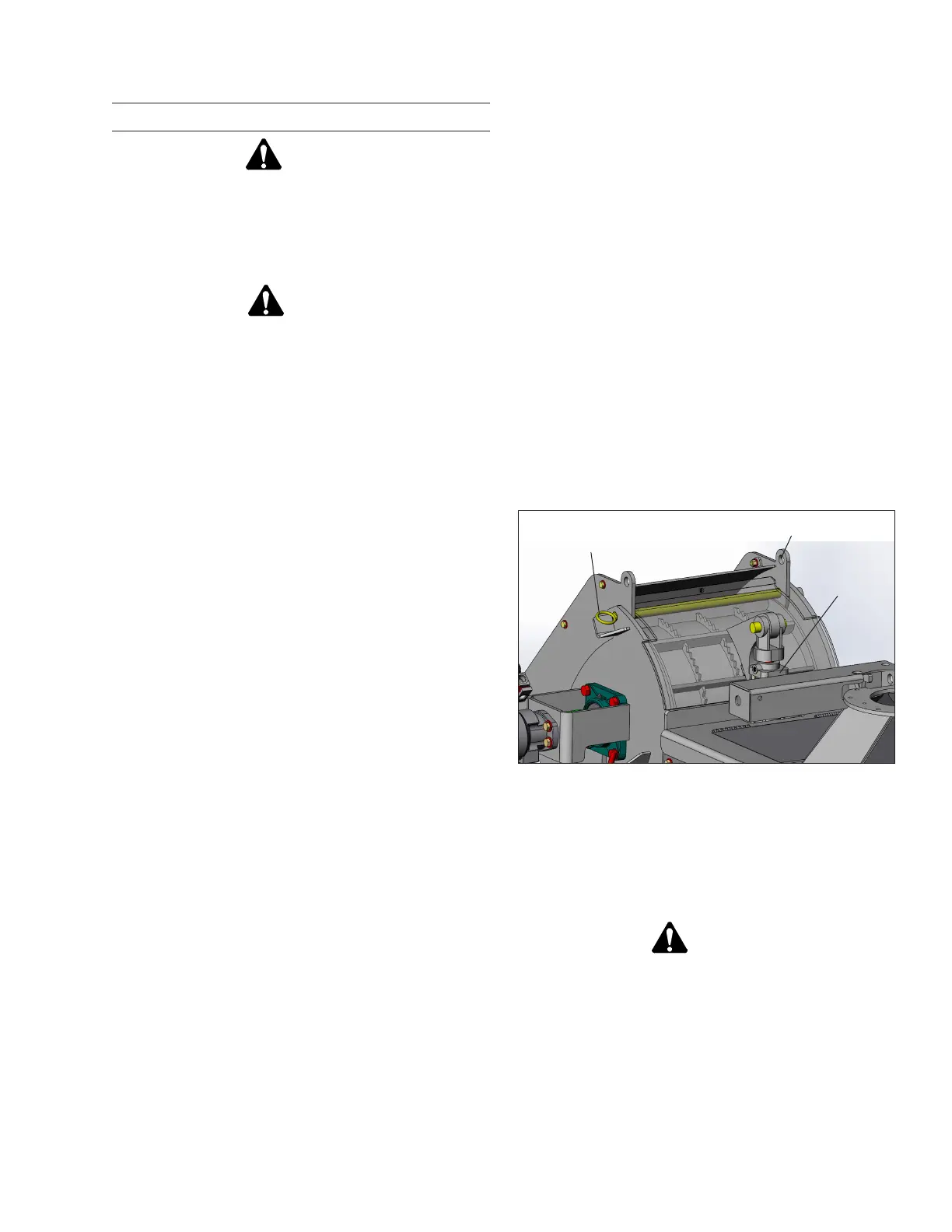

Raising the Feed Roll Assembly

1. Move feed roller control arm to the neutral position.

Make sure the feed rollers have come to a complete

stop.

2. Using the lift cylinder valve, raise the upper feed roll

assembly to its maximum position.

3. Install the upper feed roll lock pin into position (refer

to Figure 5.1).

Figure 5.1 — Feed Roll Lock Pin

4. Turn engine off and remove keys.

5. Remove negative battery cable.

6. Lock battery box.

Warning

Death, serious injury, or property damage can result

when attempting to access moving components.

Make sure components have come to a complete stop

before performing inspection or maintenance.

7. Make sure all movement of drive components and

cutter assembly have come to a complete stop.

8. Using appropriate tools remove any material interfer-

ing with the rotation of the cutter mechanism.

Lock Pin Storage

Location

Feed Roll Lock Pin

in Pinning Location

Feed Roll

Lift Cylinder

Loading...

Loading...