SYSTEM OPERATION

24

are identied as HUM and EAC. The humidier and electronic

air cleaner neutral terminals are identied as NEUTRAL. All eld

wiring must conform to applicable codes. Connections should be

made as shown. (See Figure 28.)

If it is necessary for the installer to supply additional line

voltage wiring to the inside of the furnace, the wiring must

conform to all local codes, and have a minimum temperature

rating of 105°C. All line voltage wire splices must be made

inside the furnace junction box.

The integrated control module single humidier terminal

(HUM) is energized with 115 volts whenever the induced

draft blower is energized. This terminal can also be used

to provide 115 volt power to a humidier transformer. The

remaining primary transformer wire would be connected to the

Line N on the control board. The integrated control module

electronic air cleaner terminals (EAC) are energized with 115

volts whenever the circulator blower is energized.

Wire routing must not to interfere with circulator blower

operation, lter removal, or routine maintenance.

WARNING

AVID E RISK ELECRICAL SCK INJR R DEA E

RNACE MS E ELECRICALL GRNDED IN ACCRDANCE WI LCAL

CDES R IN EIR ASENCE WI E LAES EDIIN E

N

AINAL

E

LECRIC

C

DE

WARNING

IG

VLAGE

D

ISCNNEC

ALL

PWER ERE SERVICING R

CANGING AN ELECRICAL WIRING

M

LIPLE PWER

SRCES MA E PRESEN

AILRE D S MA CASE

PRPER DAMAGE PERSNAL INJR R DEA

A 24 volt humidier can be connected to the normally open

terminal of the main pressure switch. The humidier common

would then be connected to “C” on the control board low

voltage terminal strip.

If it is necessary for the installer to supply additional line

voltage wiring to the inside of the furnace, the wiring must

conform to all local codes, and have a minimum temperature

rating of 105°C. All line voltage wire splices must be made

inside the furnace junction box.

Low voltage connections can be made through either

the right or left side panel. Wire routing must not interfere

with circulator blower operation, lter removal, or routine

maintenance.

A 40 V.A. transformer and an integrated electronic control are

built into the furnace to allow use with most cooling equipment.

Consult the wiring diagram, located in the Technical Manual

or on the blower door for further details of 115 Volt and 24

Volt wiring.

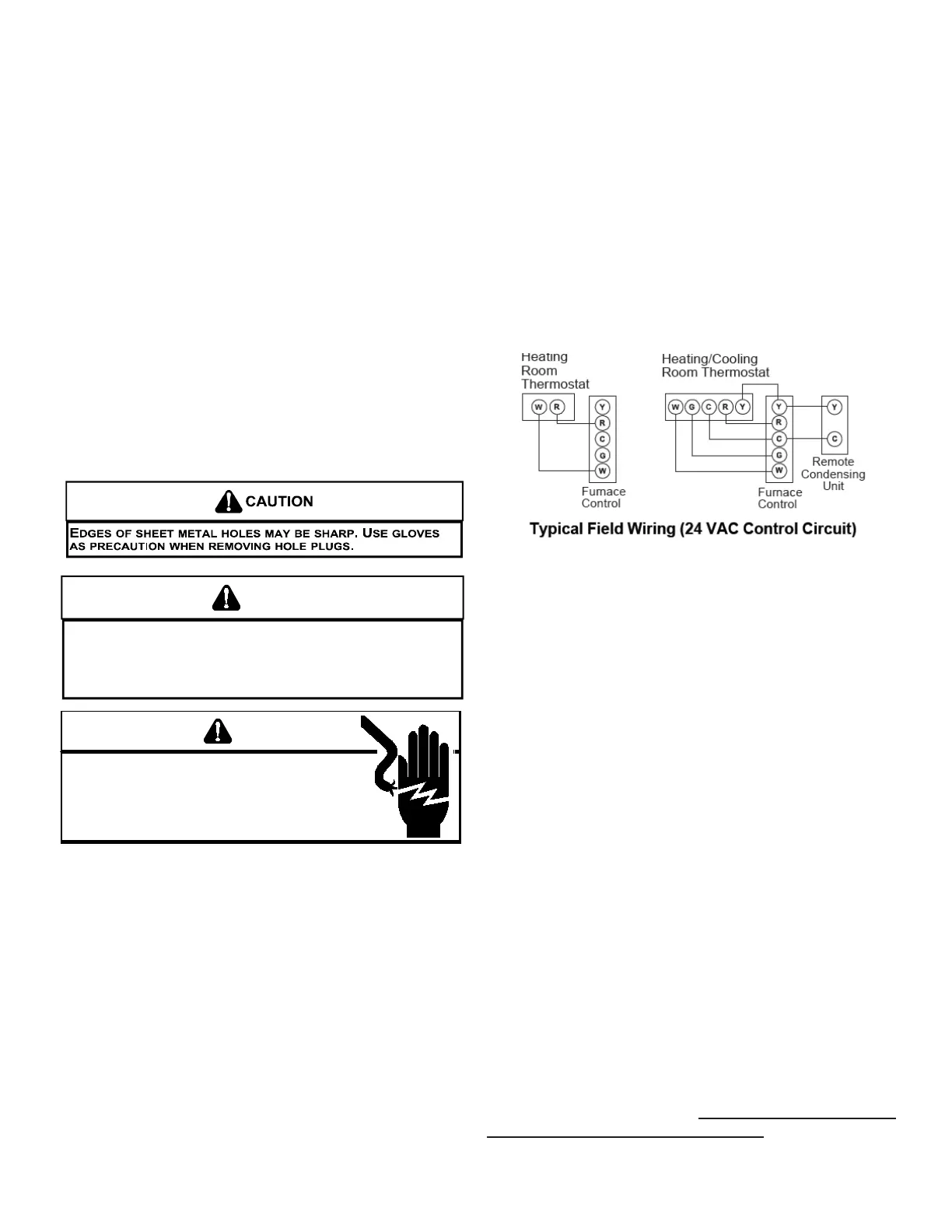

The single stage furnace will have a “W” terminal and will use

a single stage thermostat. The following drawing illustrates

the typical eld wiring for a heat only single stage system and

a single stage heating/single stage cooling system. Refer to

the following gures for proper connections to the integrated

control module.

CIRCULATING AIR AND FILTERS

Duct systems and register sizes must be properly designed

for the C.F.M. and external static pressure rating of the

furnace. Ductwork should be designed in accordance with

the recommended methods of “Air Conditioning Contractors

of America” manual D.

A duct system should be installed in accordance with

Standards of the National Board of Fire Underwriters for

the Installation of Air Conditioning, Warm Air Heating and

Ventilating Systems, Pamphlets No. 90A and 90B.

A return air lter is not supplied with the furnace. The installer

must supply a means of ltering all of the return air. Filter(s)

shall comply with UL900 or CAN/ULC-S111 Standards.

Upow furnaces with air delivery of less than 1800 CFM:

Use one side return or one bottom return ductwork connection.

Upow furnaces with air delivery of 1800 CFM or higher:

Use two side returns or one side return and one bottom return

connection.

Guide dimples locate the side and bottom return cutout

locations. Use a straight edge to scribe lines connecting the

dimples. Cut out the opening on these lines. An undersized

opening will cause reduced airflow. For bottom return

connection, remove the bottom of the cabinet before setting

the furnace on the raised platform or return air duct.

A closed return duct system must be used, with the return

duct connected to the furnace. NOTE: Ductwork must never

be attached to the back of the furnace. Supply and return

connections to the furnace may be made with exible joints

to reduce noise transmission, if desired. If a central return is

Loading...

Loading...