SERVICING

43

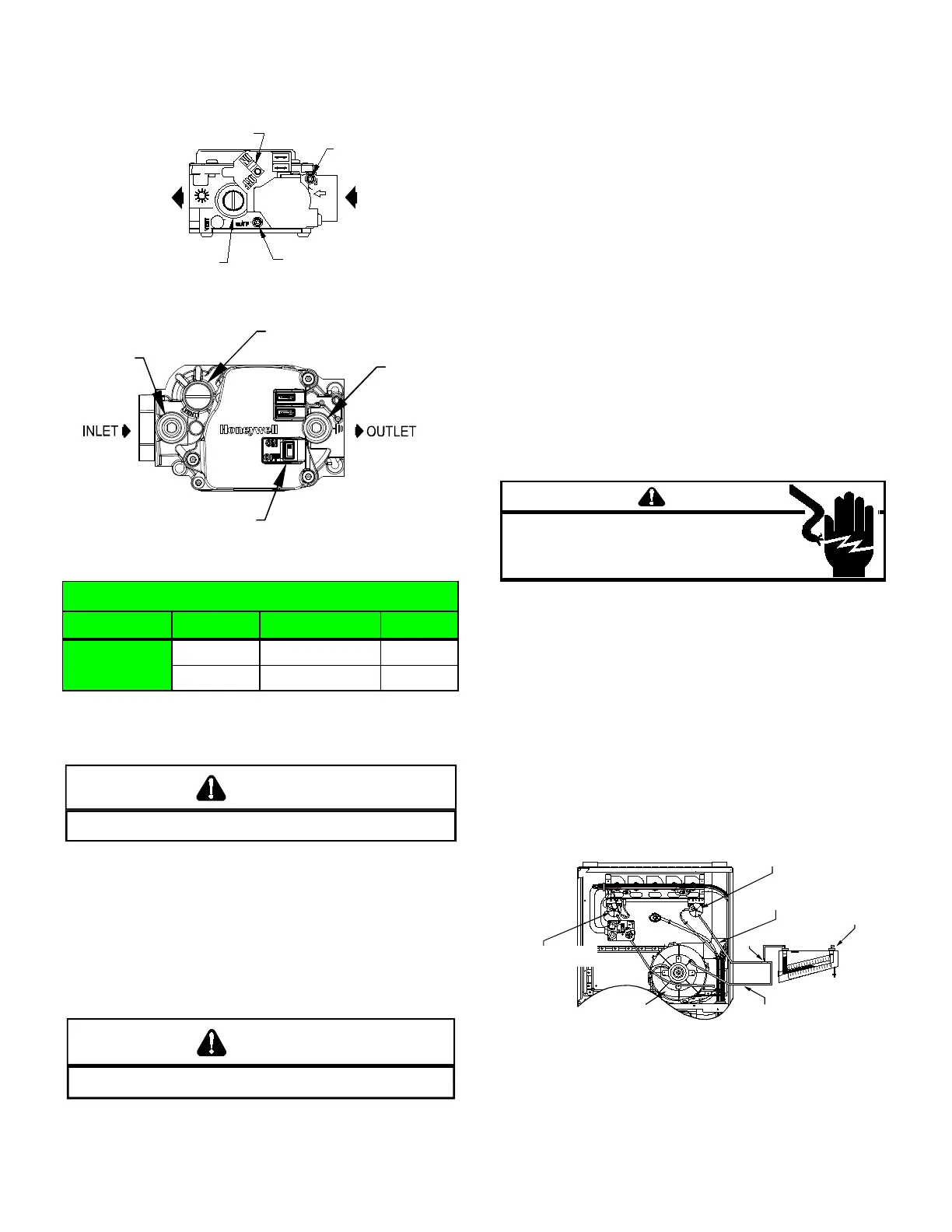

Pressure Regulator

Adjustment

(Under Cap Screw)

Gas Valve

On/Off

Selector

Switch

INLET

OUTLET

Inlet Pressure

Tap

Outlet Pressure

Tap

Gas Valve On/Off

Selector Switch

Inlet

Pressure

Ta p

Pressure Regulator

(under cap screw)

Outlet

Pressure

Ta p

Rate

High Stage 9.7 to 10.3" w.c. 10.0" w.c.

Low Stage 5.7 to 6.3" w.c.

6.0" w.c.

Single stage furnaces use a 115 volt silicon carbide igniter

(p/n 0130F00008) with 17-second warm up time.

D

ISCNNEC

ALL

PWER ERE SERVICING

WARNING

1. Remove burner compartment door to gain access to the

ignitor.

2. Ignitor cool - approximately 70 - 77°F.

3. Disconnect the ignitor from the Ignition Control.

4. Using an ohmmeter measure the resistance of the ignitor:

-at room temperature a normal reading will be 37 - 68

ohms.

5. Reconnect ignitor.

L

INE VLAGE NW PRESEN

WARNING

6. Place unit in heating cycle, measure current draw of ignitor

during preheat cycle.

Flashback will also cause burning in the burner venturi, but is

caused by the burning speed being greater than the gas-air

ow velocity coming from a burner port.

Flashback may occur at the moment of ignition, after a burner

heats up or when the burner turns o. The latter is known as

extinction pop.

Since the end results of ashback and delayed ignition can

be the same (burning in the burner venturi) a denite attempt

should be made to determine which has occurred.

If ashback should occur, check for the following:

1. Improper gas pressure - adjust to proper pressure (See

S-307 CHECKING GAS PRESSURE)..

2. Check burner for proper alignment and/or replace burner.

3. Improper orice size - check orice for obstruction.

The pressure control is a safety device to prevent the

combustion cycle from occurring with inadequate venting

caused by a restricted or blocked vent pipe.

WARNING

IG

VLAGE

D

ISCNNEC

ALL

PWER ERE SERVICING R

INSALLING IS NI

M

LIPLE PWER SRCES MA

E PRESEN

AILRE D S MA CASE PRPER

DAMAGE PERSNAL INJR R DEA

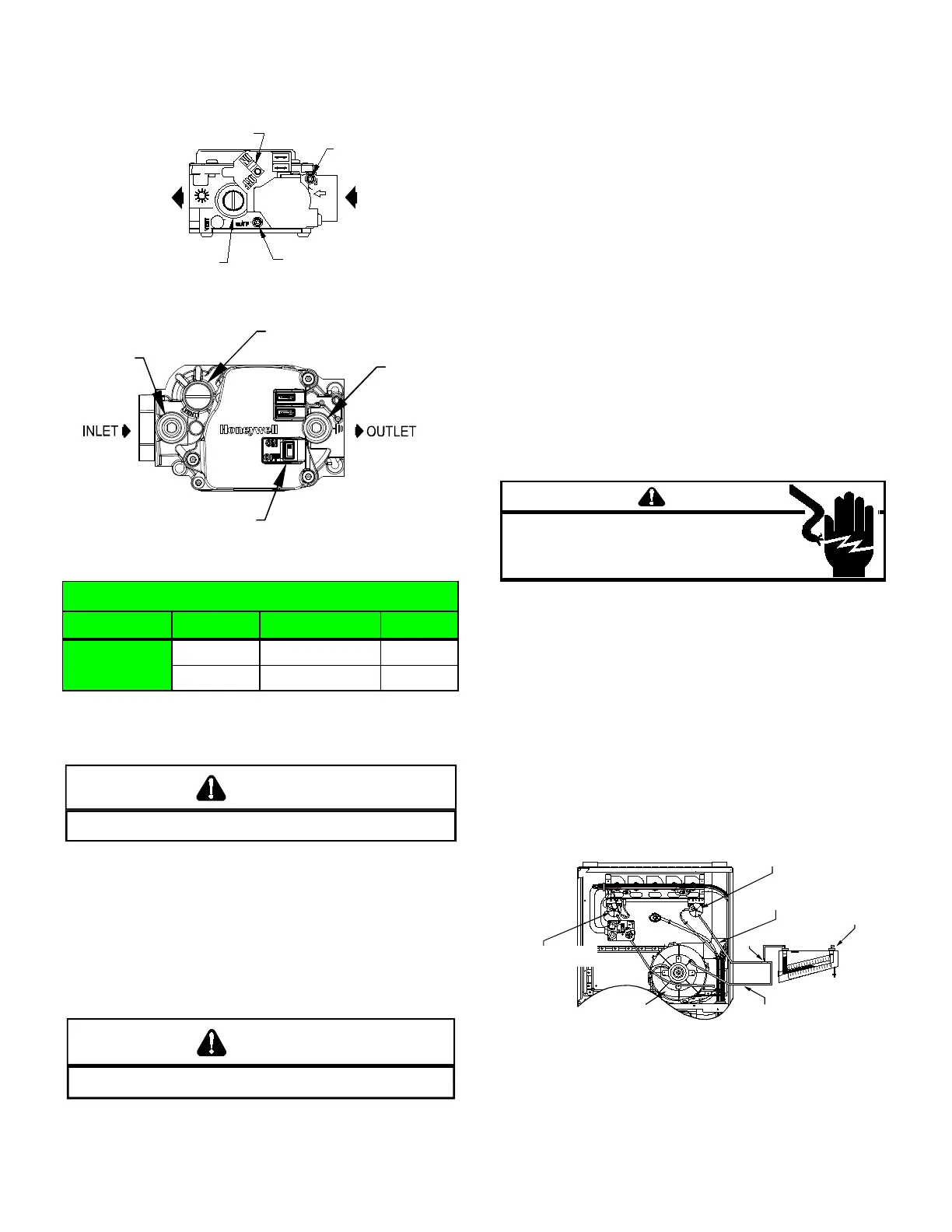

1. Remove burner compartment door to gain access to

pressure switch(es).

2. Remove wires from the pressure switch(es) electrical

terminals.

3. Remove the pressure control hose from the control and

interconnect with an inclined manometer as shown in the

following gures.

With a call for heat and the inducer running, check across the

pressure switch contacts with an ohm meter. If the contacts

are not closed, compare the negative reading on the inclined

manometer with the rating on the pressure switch to determine

whether the switch is defective or if the negative pressure is

inadequate to close the switch.

*

*

*

* *

*

*

M

1

2

3P

C

ON

O

F

F

A high altitude kit is required for installationsabove 7,000 ft.

Refer to the accessory matrix in this manual to determine

the proper natural gas and LP gas high altitude kit for your

furnace.

Loading...

Loading...