SERVICING

41

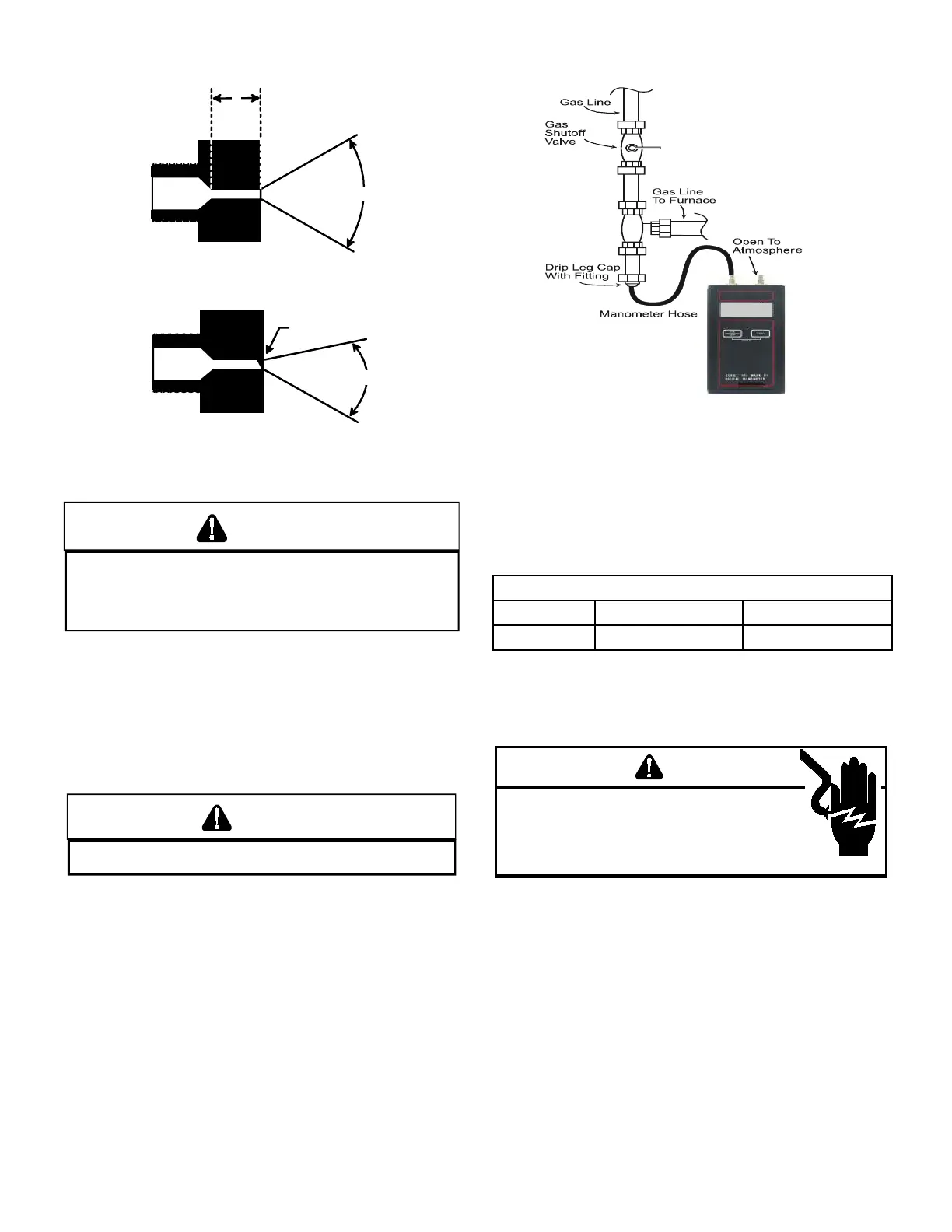

The length of Dimension “A” determines the angle of Gas

Stream “B”.

A dent or burr will cause a severe deection of the gas stream.

PREVEN NRELIALE PERAIN R EQIPMEN DAMAGE E

INLE GAS SPPL PRESSRE MS E AS SPECIIED N E NI

RAING PLAE WI ALL ER SELD GAS IRED APPLIANCES

PERAING

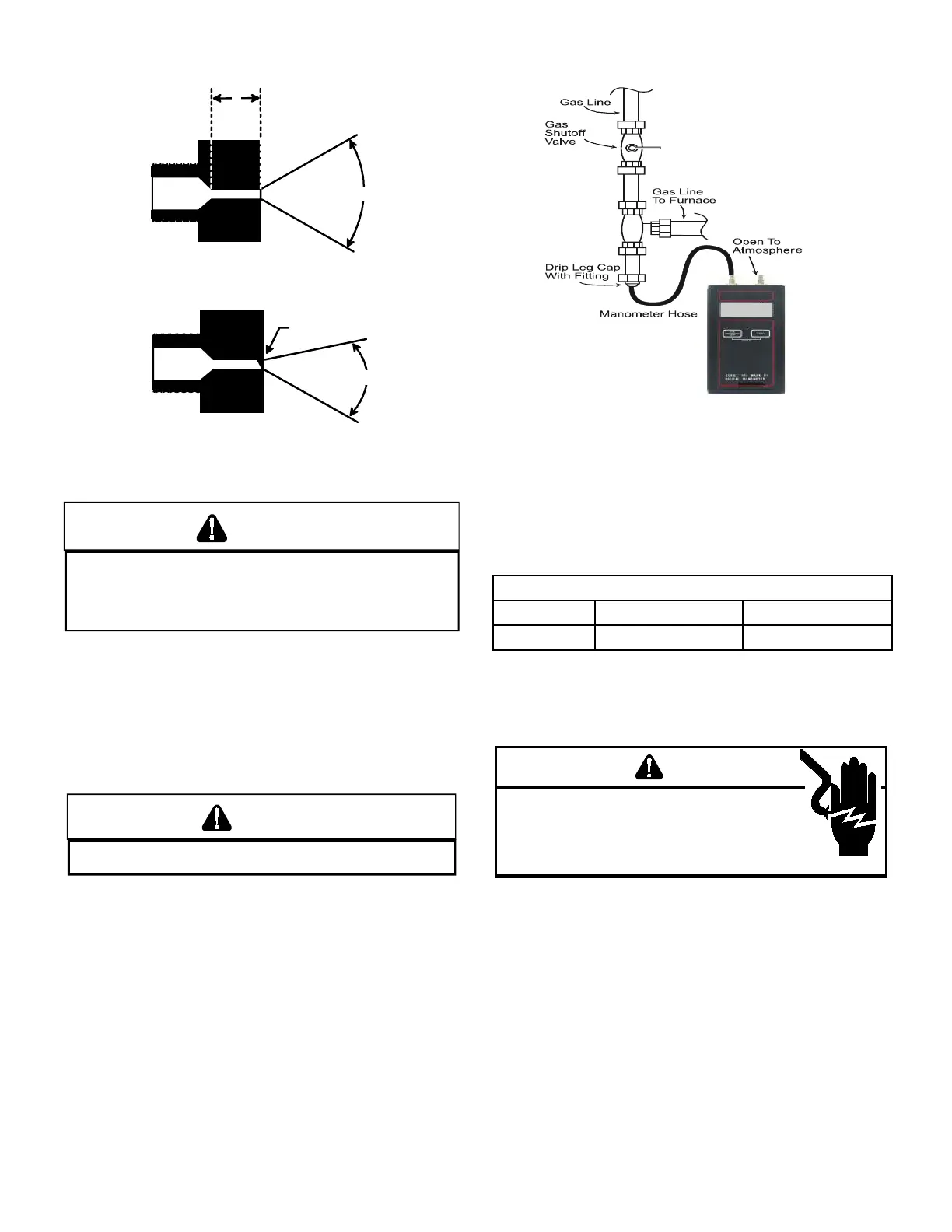

Gas inlet and manifold pressures should be checked and

adjusted in accordance to the type of fuel being consumed.

The line pressure supplied to the gas valve must be within the

range specied below. The supply pressure can be measured

at the gas valve inlet pressure tap or at a hose tting installed

in the gas piping drip leg. The supply pressure must be

measured with the burners operating. To measure the gas

supply pressure, use the following procedure.

WARNING

DISC

NNEC ELECRICAL PWER AND S GAS SPPL

1. After turning o gas to furnace at the manual gas shuto

valve external to the furnace, remove burner compartment

door to gain access to the gas valve.

2. Connect a calibrated water manometer (or appropriate

gas pressure gauge) at either the gas valve inlet pressure

tap or the gas piping drip leg as shown in the following

gures.

At either location, a hose tting must be installed prior

to making the hose connection.

Use adapter kit #0151K00000S to measure gas

pressure on White-Rodgers 36G22 gas valves.

3. Turn ON the gas and electrical power supply and operate

the furnace and all other gas consuming appliances on

the same gas supply line.

4. Measure furnace gas supply pressure with burners ring.

Supply pressure must be within the range specied in the

following table.

Natural Gas Minimum: 4.5" w.c. Maximum: 10.0" w.c.

Propane Gas Minimum: 11.0" w.c. Maximum: 13.0" w.c.

If supply pressure differs from above, make necessary

adjustments to pressure regulator, gas piping size, etc., and/

or consult with local gas utility.

WARNING

IG

VLAGE

D

ISCNNEC

ALL

ELECRICAL PWER AND S GAS

SPPL ERE SERVICING R INSALLING IS NI

M

LIPLE PWER SRCES MA E PRESEN

AILRE

D S MA CASE PRPER DAMAGE PERSNAL INJR R DEA

5. Disconnect manometer after turning o gas at manual

shuto valve. Reinstall plug before turning on gas to

furnace.

6. Turn OFF any unnecessary gas appliances started in step

3.

7. Turn on gas to furnace and check for leaks. If leaks are

found, repair and then reinstall burner compartment door.

8. Turn on electrical power and verify proper unit operation.

Loading...

Loading...