SERVICING

37

5. If line voltage available at primary voltage side of trans-

former and wiring and splices good, transformer is inop-

erative. Replace.

S-6 CHECKING TIME DELAY RELAY

Time delay relays are used in Amana

®

brand Package Units

to improve efficiency by delaying the blower off time. This

feature is incorporated into the electronic controls. See S-

23 to check control board.

S-7 CHECKING CONTACTOR AND/OR RELAYS

The compressor contactor and other relay holding coils are

wired into the low or line voltage circuits. When the control

circuit is energized the coil pulls in the normally open con-

tacts or opens the normally closed contacts. When the coil

is de-energized, springs return the contacts to their normal

position.

WARNING

HIGH

VOLTAGE

D

ISCONNECT ALL POWER BEFORE SERVICING OR

INSTALLING THIS UNIT.

M

ULTIPLE POWER SOURCES MAY

BE PRESENT.

FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

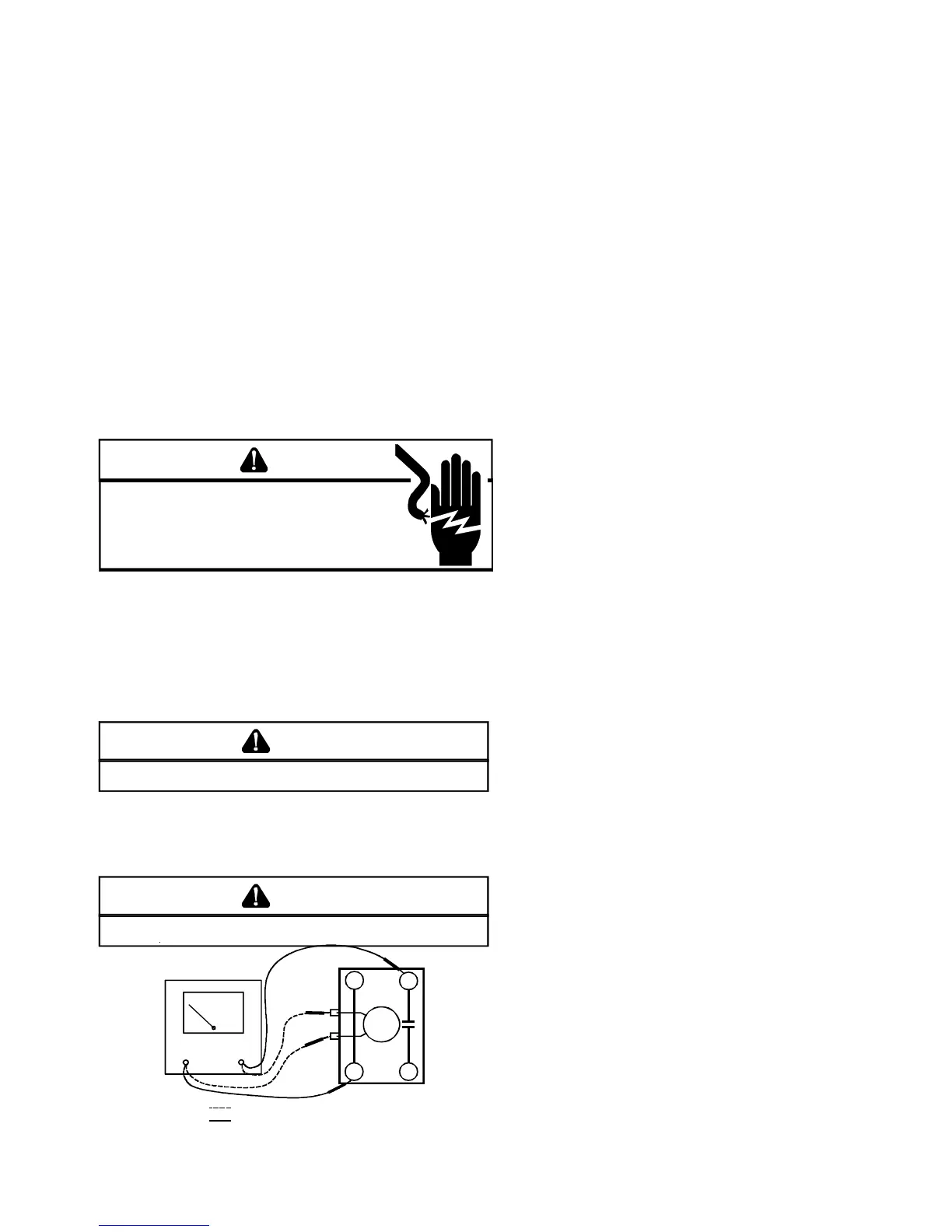

1. Remove the leads from the holding coil.

2. Using an ohmmeter, test across the coil terminals.

If the coil does not test continuous, replace the relay or

contactor.

S-8 CHECKING CONTACTOR CONTACTS

WARNING

D

ISCONNECT ELECTRICAL POWER SUPPLY.

1. Disconnect the wire leads from the terminal (T) side of

the contactor.

2. With power ON, energize the contactor.

WARNING

L

INE VOLTAGE NOW PRESENT.

3. Using a voltmeter, test across terminals.

A. L2 - T1 - No voltage indicates CC1 contacts open.

If a no voltage reading is obtained - replace the contactor.

S-9 CHECKING FAN RELAY CONTACTS

The fan relays are incorporated into the control board. See

sections S-23 for checking control board.

NOTE: Some variation over time has occurred in the fan re-

lays used. Refer to the unit wiring diagram for terminal iden-

tification.

S-15 CHECKING CAPACITOR

CAPACITOR, RUN

A run capacitor is wired across the auxiliary and main wind-

ings of a single phase permanent split capacitor motor. The

capacitors primary function is to reduce the line current while

greatly improving the torque characteristics of a motor. This

is accomplished by using the 90° phase relationship between

the capacitor current and voltage in conjunction with the motor

windings so that the motor will give two phase operation when

connected to a single phase circuit. The capacitor also re-

duces the line current to the motor by improving the power

factor.

CAPACITOR, START

SCROLL COMPRESSOR MODELS

Hard start components are not required on Scroll compres-

sor equipped units due to a non-replaceable check valve lo-

cated in the discharge line of the compressor. However hard

start kits are available and may improve low voltage starting

characteristics.

This check valve closes off high side pressure to the com-

pressor after shut down allowing equalization through the scroll

flanks. Equalization requires only about one or two seconds

during which time the compressor may turn backwards.

To prevent the compressor from starting and running back-

wards a Time Delay Relay (Cycle Protector) has been added

to the low voltage circuit.

NOTE: K3 series scroll compressors have an anti-rotation

device and equalizing mechanism incorporated into the com-

pressor and will equalize in 0.2 to 0.3 seconds. These com-

pressors will operate correctly without a Time Delay Relay.

MODELS EQUIPPED WITH A HARD START DEVICE

A start capacitor is wired in parallel with the run capacitor to

increase the starting torque. The start capacitor is of the

electrolytic type, rather than metallized polypropylene as used

in the run capacitor.

A switching device must be wired in series with the capacitor

to remove it from the electrical circuit after the compressor

starts to run. Not removing the start capacitor will overheat

the capacitor and burn out the compressor windings.

VOLT/OHM

METER

T1

T2

L1L2

CC

Ohmmeter for testing holding coil

Voltmeter for testing contacts

TESTING COMPRESSOR CONTACTOR

Loading...

Loading...