SERVICING

42

NOTE: You must use the correct replacement control motor module since they are factory programmed for specific operating modes. Even though

they look alike, different modules may have completely different functionality. The ECM variable speed motors are currently the only motors that

can have the motor/control module replaced.

IMPORTANT NOTE: Using the wrong motor/control module voids all product warranties and may produce unexpected results.

*MOISTURE CHECK:

- Connectors are oriented "down" (or as recommended

by equipment manufacturer).

- Arrange harnesses with "drip loop" under motor.

- Is condensate drain plugged?

- Check for low airflow (too much latent capacity).

- Check for undercharged condition.

- Check and plug leaks in return ducts, cabinet.

CHART CONTINUED ON NEXT PAGE.

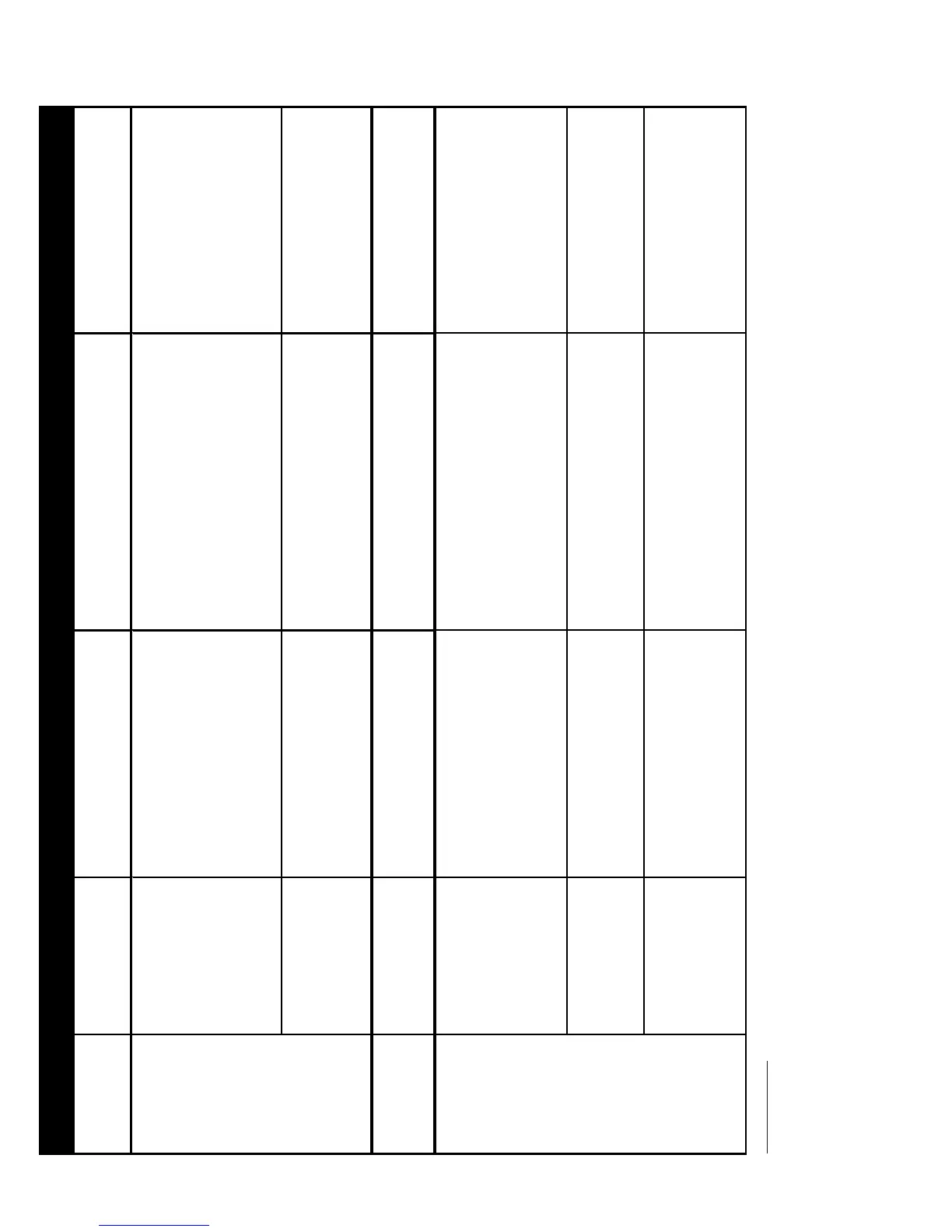

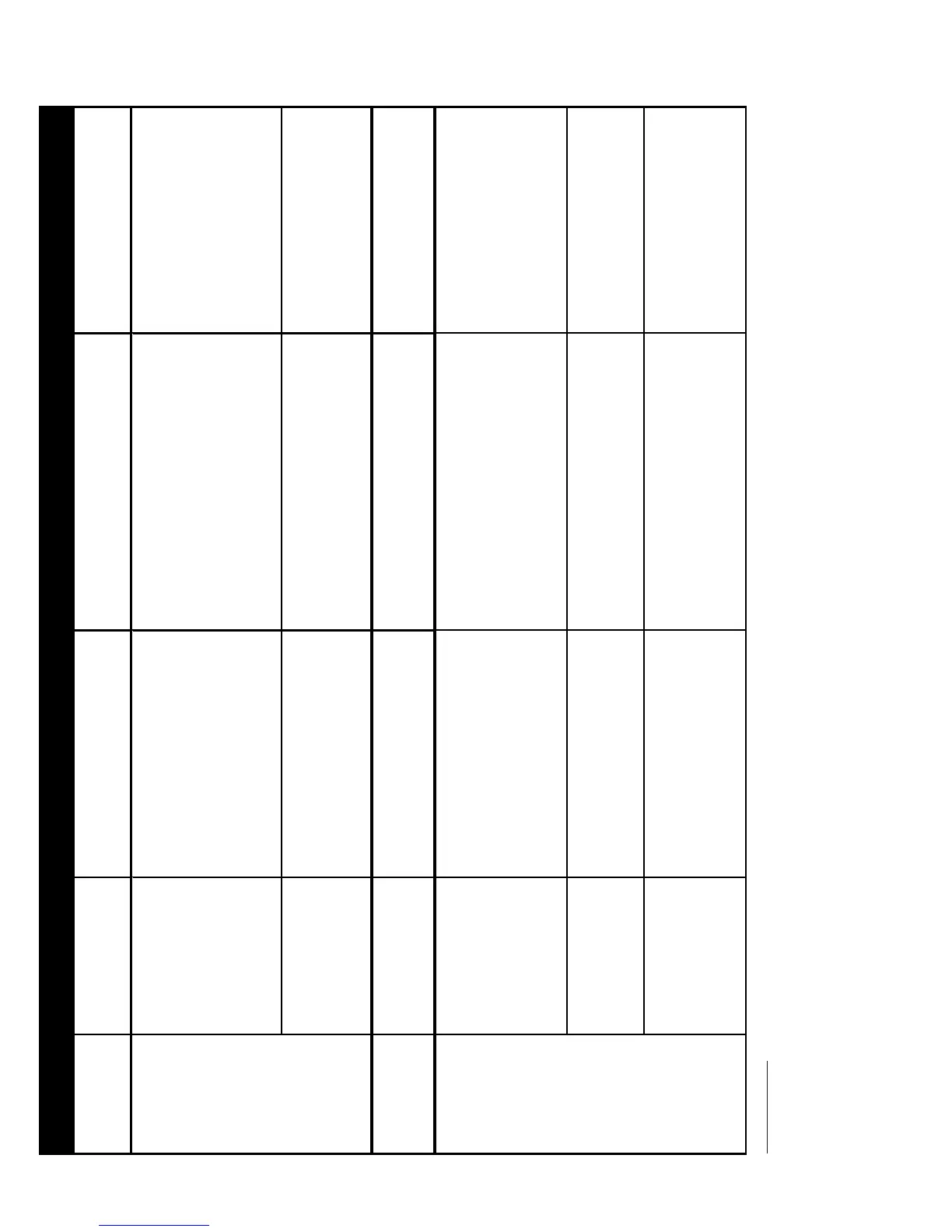

Symptom Fault Description(s) Possible Causes Corrective Action Cautions and Notes

- Motor rocks

slightly when

starting.

- This is normal start-up

for variable speed motor.

---- ---- ----

- No movement.

- Manual disconnect switch off or

door switch open.

- Blown fuse or circuit breaker.

- 24 Vac wires miswired.

- Unseated pins in wiring harness

connectors.

- Bad motor/control module.

- Moisture present in motor or

control module.

- Check 230 Vac power at motor.

- Check low voltage (24 Vac R to C)

at motor.

- Check low voltage connections (G, Y, W, R, C)

at motor.

- Check for unseated pins in connectors on

motor harness.

- Test with a temporary jumper between R - G.

- Check motor for tight shaft.

- Turn power OFF prior to repair.

Wait 5 minutes after disconnecting

power before opening motor.

- Handle electronic motor/contro

with care.

- Motor rocks,

but won't start.

- Loose motor mount.

- Blower wheel not tight on motor shaft.

- Bad motor/control module.

- Check for loose motor mount.

- Make sure blower wheel is tight on shaft.

- Perform motor/control replacement check,

ECM motors only.

- Turn power OFF prior to repair.

Wait 5 minutes after disconnecting

power before opening motor.

- Handle electronic motor/control

with care.

- Motor oscillates

up & down while

being tested off

of blower.

- It is normal for motor to

oscillate with no

load on shaft.

---- ---- ----

- Varies up and down

or intermittent.

- Variation in 230 Vac to motor.

- Unseated pins in wiring harness

connectors.

- Erratic CFM command from "BK" terminal.

- Improper thermostat connection

or setting.

- Moisture present in

motor/control module.

- Check line voltage for variation or "sag".

- Check low voltage connections (G, Y, W, R, C)

at motor, unseated pins in motor

harness connectors.

- Check-out system controls - Thermostat.

- Perform Moisture Check.*

- Turn power OFF prior to repair.

- "Hunts" or "puffs" at

high CFM (speed).

- Incorrect or dirty filter(s).

- Incorrect supply or return ductwork.

- Incorrect blower speed setting.

- Does removing panel or filter reduce "puffing"?

- Check/replace filter.

- Check/correct duct restrictions.

- Adjust to correct blower speed setting.

- Turn power OFF prior to repair.

- Stays at low CFM

despite system call for

cool or heat CFM.

- 24 Vac wires miswired or loose.

- "R" missing/not connected at motor.

- Fan in delay mode.

- Check low voltage (Thermostat) wires

and connections.

- Verify fan is not in delay mode - wait until delay

complete.

- Perform motor/control replacement check,

ECM motors only.

- Turn power OFF prior to repair.

Wait 5 minutes after disconnecting

power before opening motor.

- Handle electronic motor/control

with care.

TROUBLESHOOTING CHART FOR ECM VARIABLE SPEED AIR CIRCULATOR BLOWER MOTORS

- Motor won't start.

- Motor starts,

but runs

erratically.

Loading...

Loading...