American Eagle

®

65R Compressor Manual | Page 5

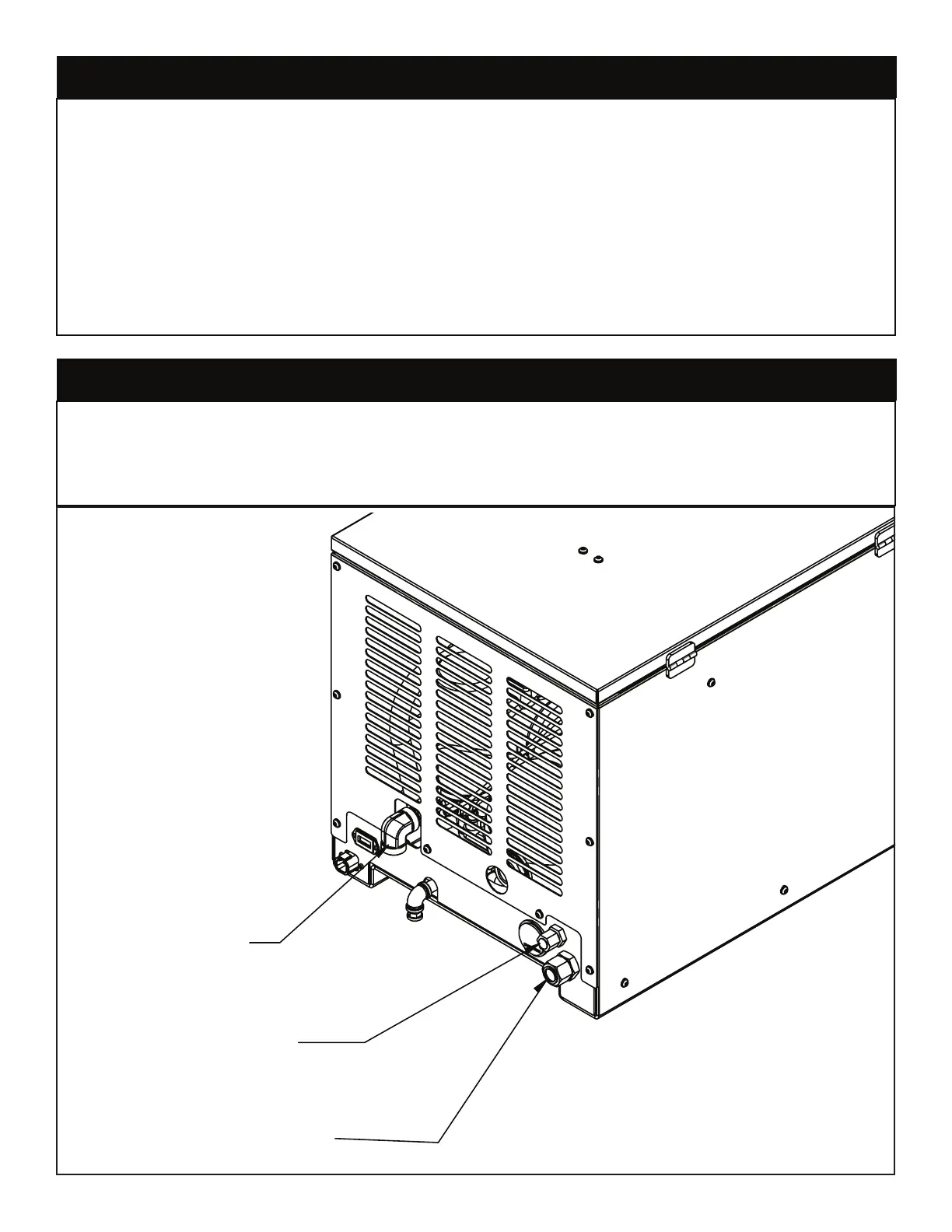

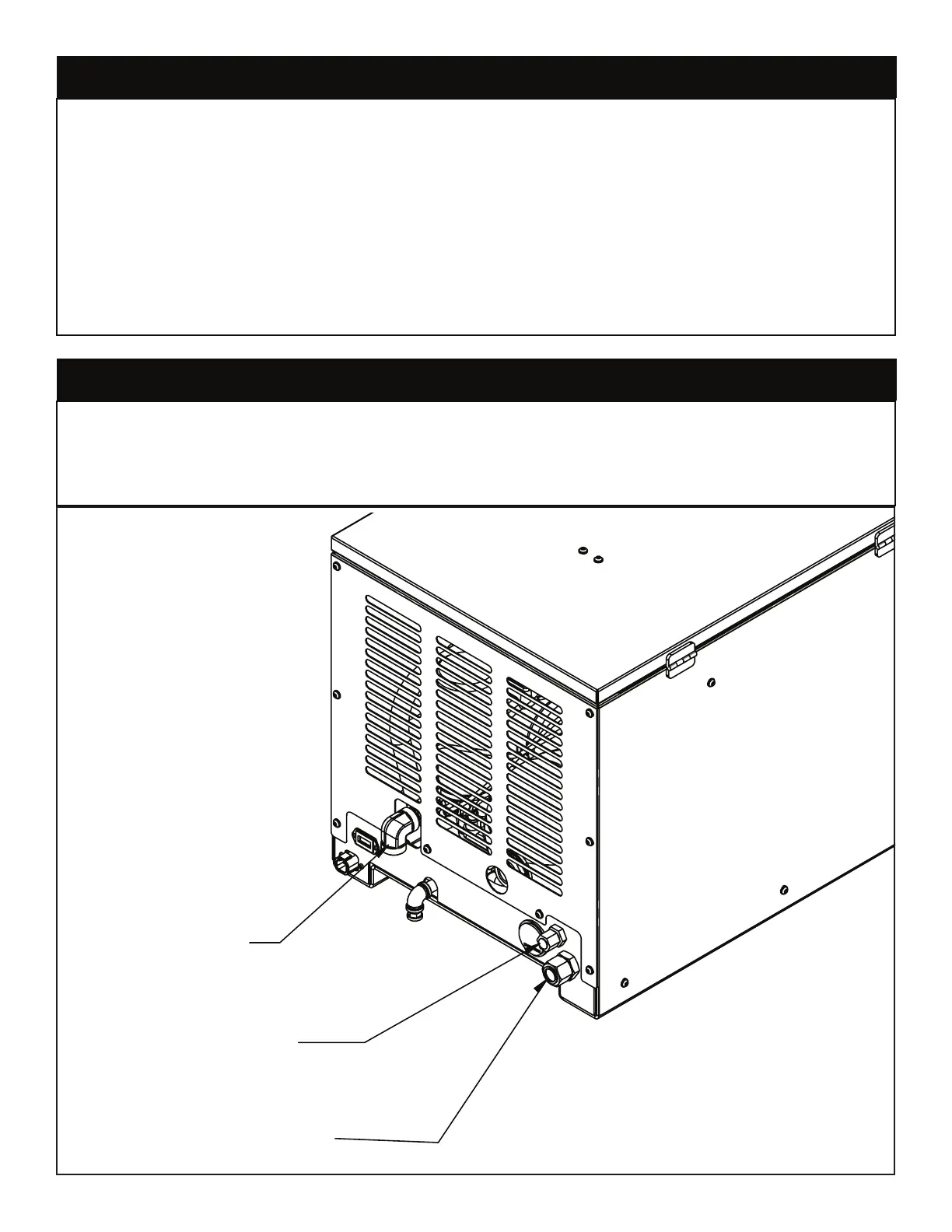

The hydraulic system consists of the pump, oil reservoir, filters and hoses. Installed on the

compressor is a valve block assembly that controls the flow to the hydraulic motor. To this

block, a 1/2” high-pressure hose must be attached. This hose comes from the pressure

side of the hydraulic pump. A 3/4” minimum low-pressure return line is connected to the

oil cooler outlet and is routed to the oil reservoir. American Eagle recommends a sufficient

sized reservoir be provided that includes the proper suction and return filters. The cooler on

the compressor is designed and sized to cool the air compressor efficiently. An auxiliary

oil cooler is required when additional hydraulically operated equipment are added to

the hydraulic system. Pressure on the return line exceeding 200 PSI can and will cause

damage to the filter, cooler, and components of the compressor hydraulic system.

The airline is routed using a 3/4” (200 psi) air hose. This delivery line should be free from all

obstructions. Note: There should be no check valve installed between the compressor

and the air tank. American Eagle recommends the installation of a ten gallon air tank

(minimum) to maintain proper operation of the air compressor.

Hydraulic System

Air System

AIR DISCHARGE

-12 FEMALE NPT

HYDRAULIC PRESSURE

-8 MALE FACE SEAL

HYDRAULIC DISCHARGE

-12 FACE SEAL

Loading...

Loading...