Installation 13

Pump Assembly:

The pump assembly may either be installed

directly on the PTO or as an optional method,

may be driven by a driveline from the PTO.

Pump manufacturers provide specific installation

information for their products and should be

consulted if questions arise.

PTO Assembly:

Check with the PTO manufactures

representative for specific instructions regarding

your particular make, model, and year of vehicle.

As some trucks may require modification of the

transmission cross member and the exhaust

system, the manufacturer’s instructions should

be followed to insure proper installation of the

PTO.

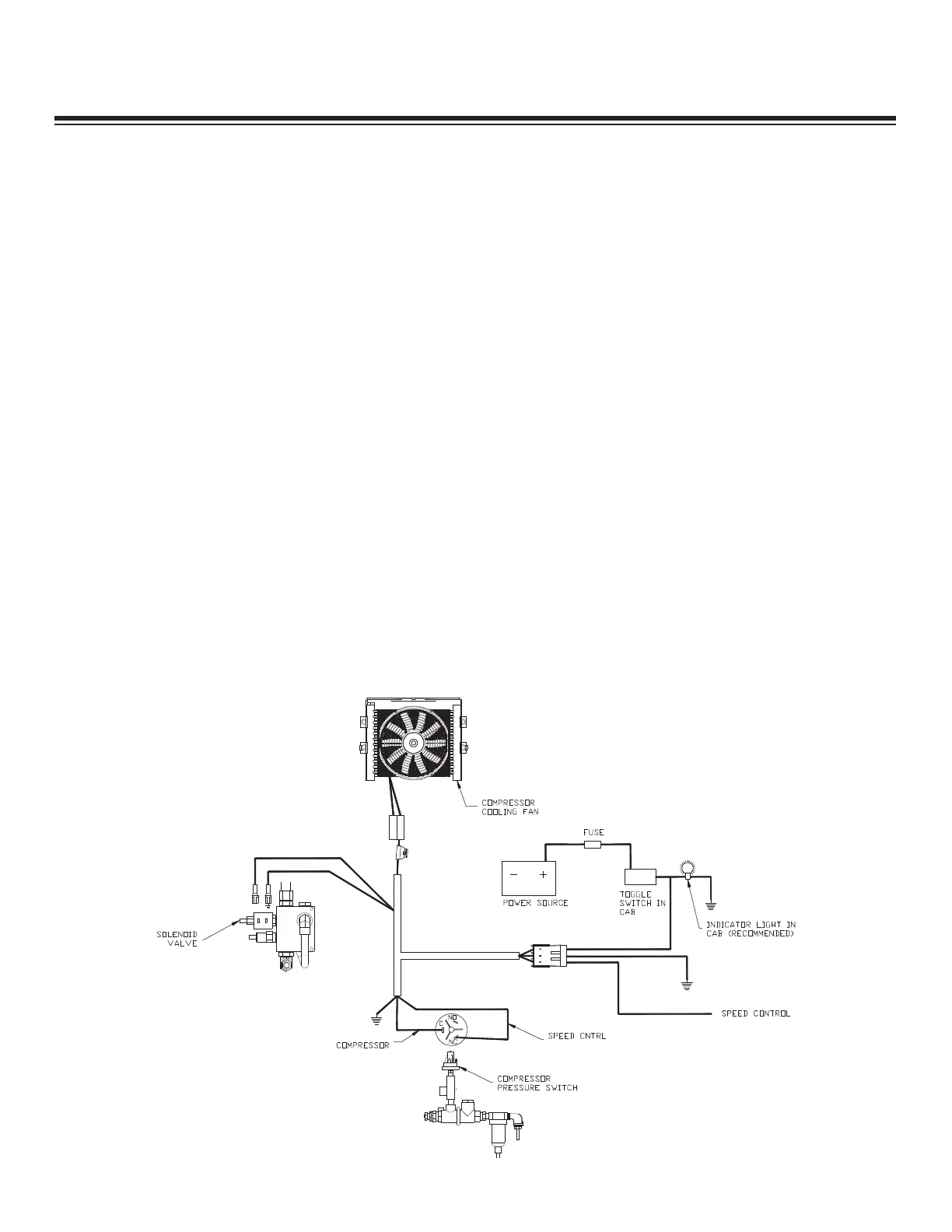

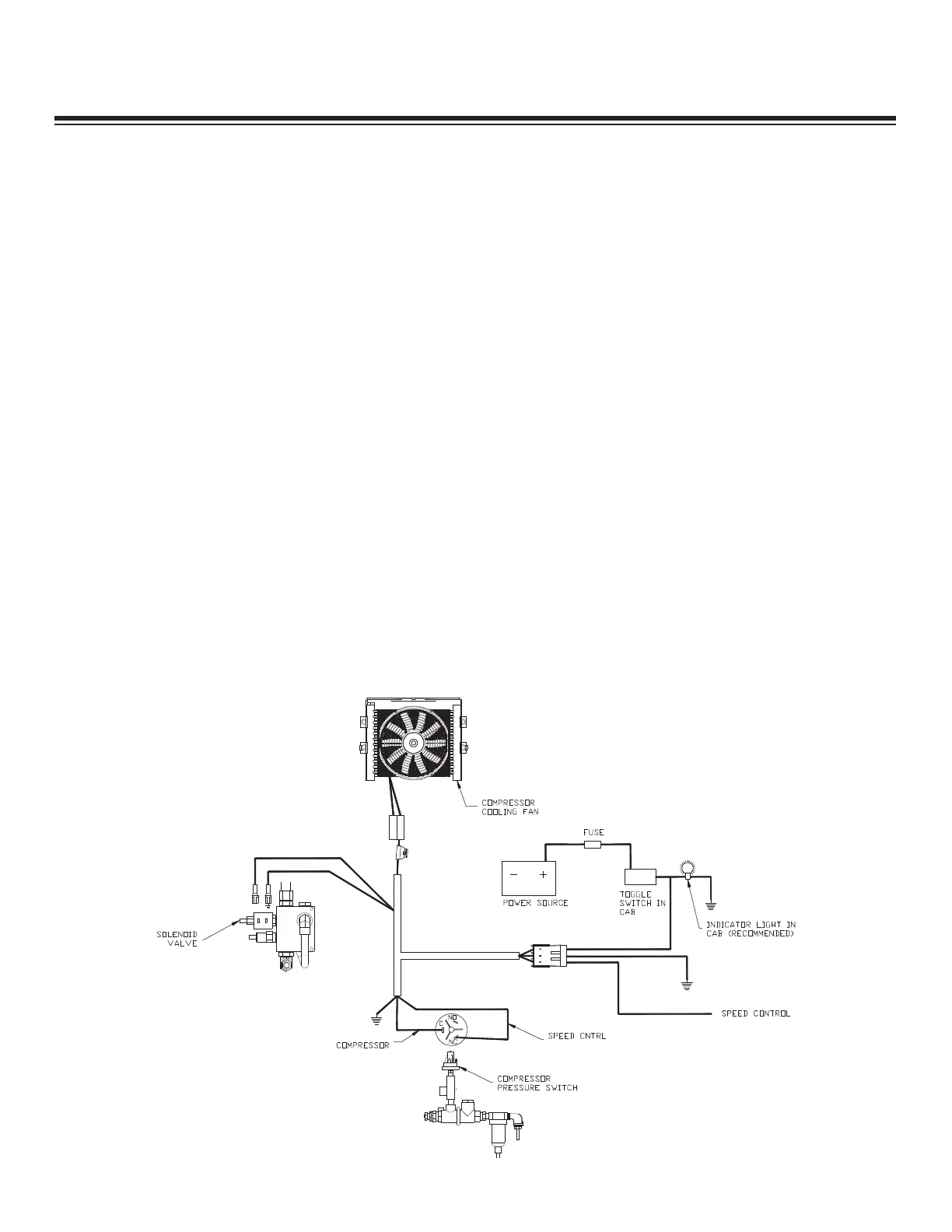

Compressor Assembly:

Prepare the mounting location of the compressor

by locating and drilling four (4) holes, 9/16”

diameter as per the mounting pattern of the air

compressor base. Using four (4) 1/2” x 1.50”

GR-5 cap screws, 1/2” flat washer, and 1/2”

nyloc nut, secure the compressor in place. The

compressor is air cooled, and must have a clean

supply of cooling air to the fan with minimum

restrictions. Adequate space must be provided

for proper circulation of air.

Electric speed control:

An optional electric or electronic speed control

must be used to maintain proper operating

speed of the air compressor. The engine speed

control will automatically increase from idle to a

preset speed when engaged and decrease when

disengaged.

COMPONENT INSTALLATION

This section pertains to the installation of the air compressor, PTO, pump and other related items.

The instructions are intended as a guide to assist you with particular installation. These instructions

will provide only general information.

Chapter 5: Installation

Loading...

Loading...