28 User Manual EN Dansensor® ISM-3

P/N 200114-I

09/2021

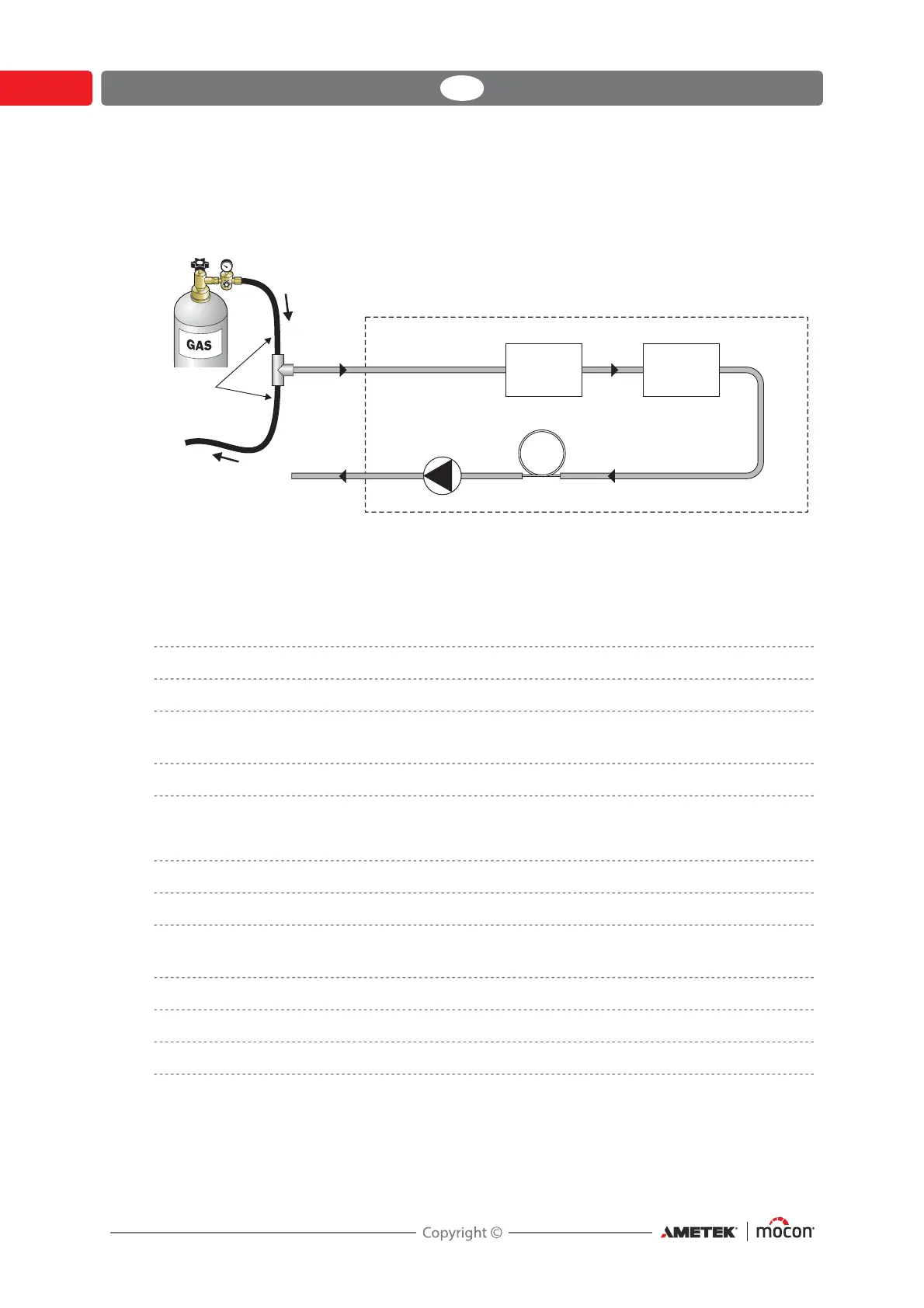

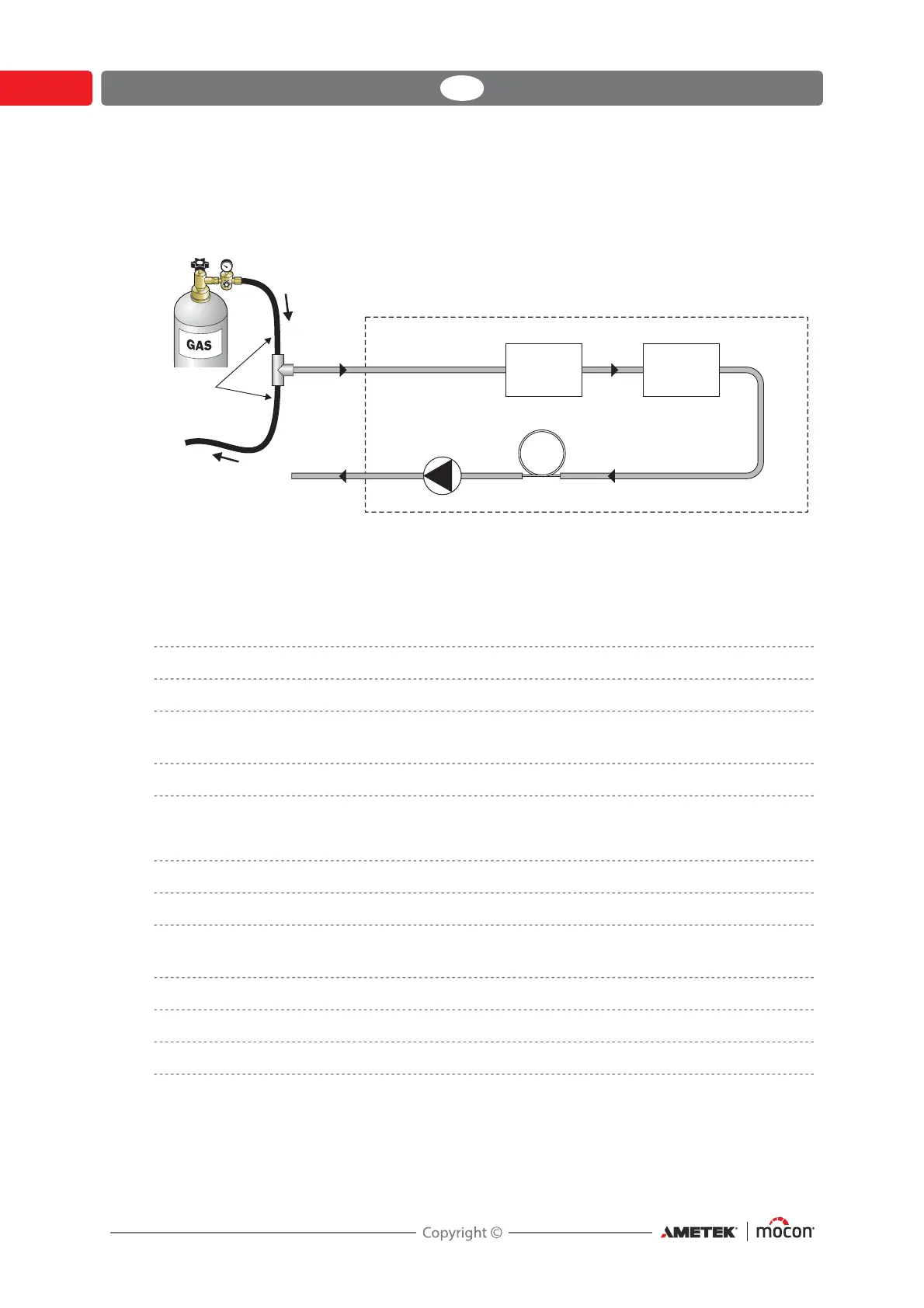

If the ISM-3 is equipped with an internal pump, the gas is sucked from measure point at

atmospheric pressure. When calibrating, the gas is sucked from a gas overflow, to which

approx. 0.5 l/min must be supplied.

Fig. 6. Flow diagram of ISM-3 with pump. Gas overflow for calibration use is shown

Operation and connection

Operation of ISM-3:

Display 4 digit red LED display

Control 4 front keys. Key function is activated when key is released.

Measuring accuracy Better than +/- 1% of the measured value

+/- 1 digit in calibrated measuring range

Measuring range 20.9% - 1ppm (standard) *

* For measuring in other ranges device must be recalibrated - see "Calibration" on page 19 for details

Possible connection to the ISM-3:

Gas supply Gas inlet on the back

Relay Max. 48V, 1A. (COMMON, N.O. and N.C.)

Current output Programmable 0-20 or 4-20 mA, with user-defined scale

(e.g. 0-1%, 10-20.9% or 0-100ppm O

2

).

Voltage output (Option) Programmable 0-10 volt or 2-10 volt with user defined scale

Measure input 10-32VDC external pump control. Consumption 10mA.

RS232C (Option) For serial communication with a PC (for internal use only)

All electrical inputs and outputs, except for the RS232C port, is galvanically separated from

the internal electronics by means of optocouplers and/or a relay.

(for flow indication)

Restriction hose

Gas out

125 ml/min

Pump

Gas in

0,5 l/min

Hoses:

ID = min. 3 mm

L = min. 0.5 m

O

2

sensor

Pressure

sensor

Loading...

Loading...