10

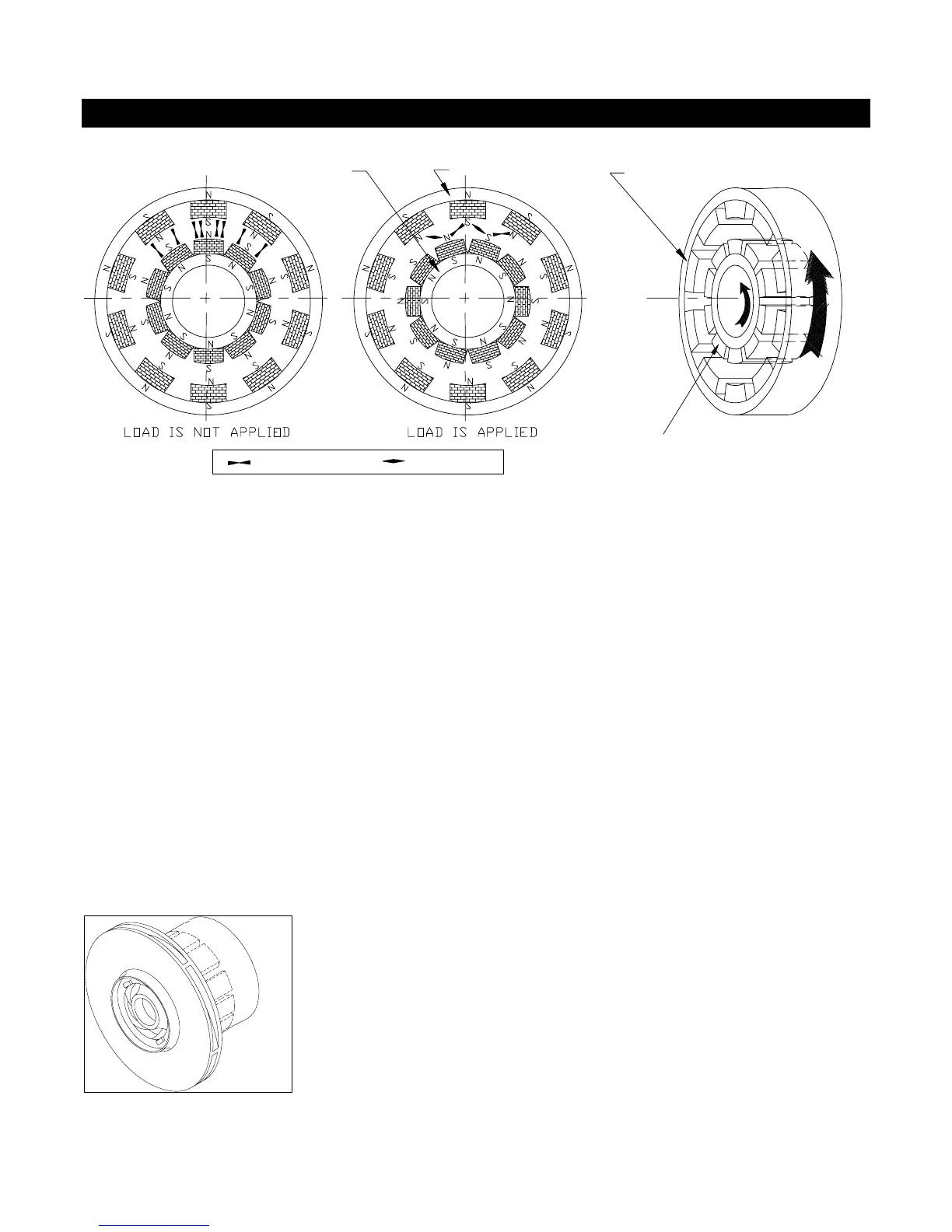

4. PRINCIPLES OF MAGNETIC DRIVE PUMPS

INNER YOKE

OUTER YOKE

OUTER MAGNET ASSEMBLY

INNER MAGNET ASSEMBLY

ATTRACTION REPULSION

Fig. 4-1

A magnetic coupling consists of two magnet assemblies. One is the outer assembly (the driver magnet)

and the other is the inner assembly (the driven magnet). The outer assembly is connected to a motor and

the inner assembly is indirectly or directly attached to a pump impeller. As Figure 4-1 shows, at rest,

magnet components of the outer assembly are aligned with their counterparts in the inner assembly.

When load (torque) is applied, the coupling deflects angularly and the magnets create a force of

simultaneous attraction and repulsion. This force is used to transfer torque from the motor to the

impeller.

This permanent-permanent magnet coupling creates neither slippage nor induction currents during

rotation. If excessive torque is applied, the magnets will de-couple. The magnets will not re-couple

unless the pump is stopped. There is no energy loss in this permanent-permanent coupling unless an

electrically conductive containment is placed between the outer and inner magnets. If an electrically

conductive material is used for the containment, eddy-currents will be generated which will cause some

energy loss. Ansimag's K+ Series pumps use only non-conductive containment shells. Ansimag's

K+ Series pumps have an inner magnet assembly which is indirectly attached to the impeller

(CFR/ETFE) or directly molded into the impeller (GFR/PFA ). The magnets are shown in Figure 4-2

behind the impeller.

Fi

. 4-2

Loading...

Loading...