21

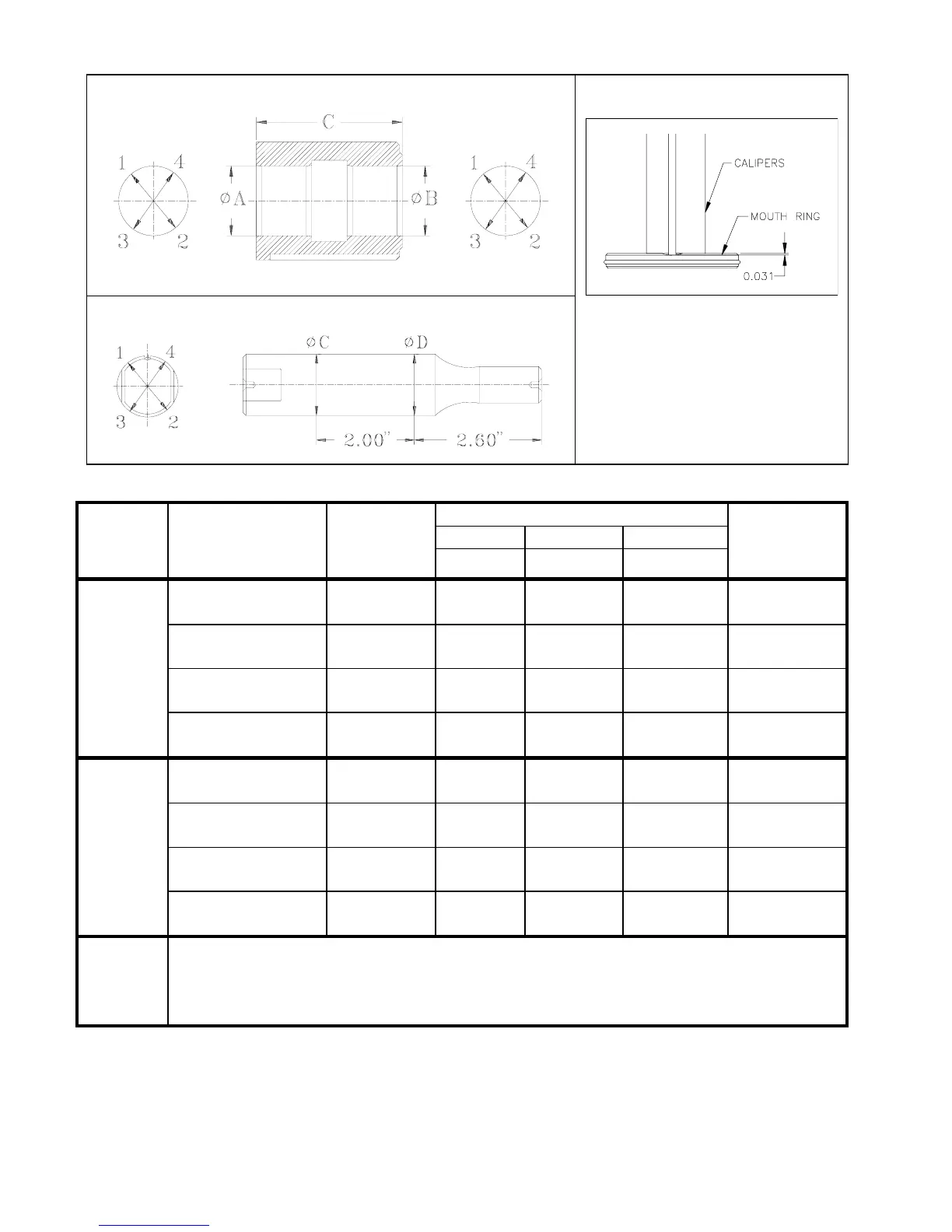

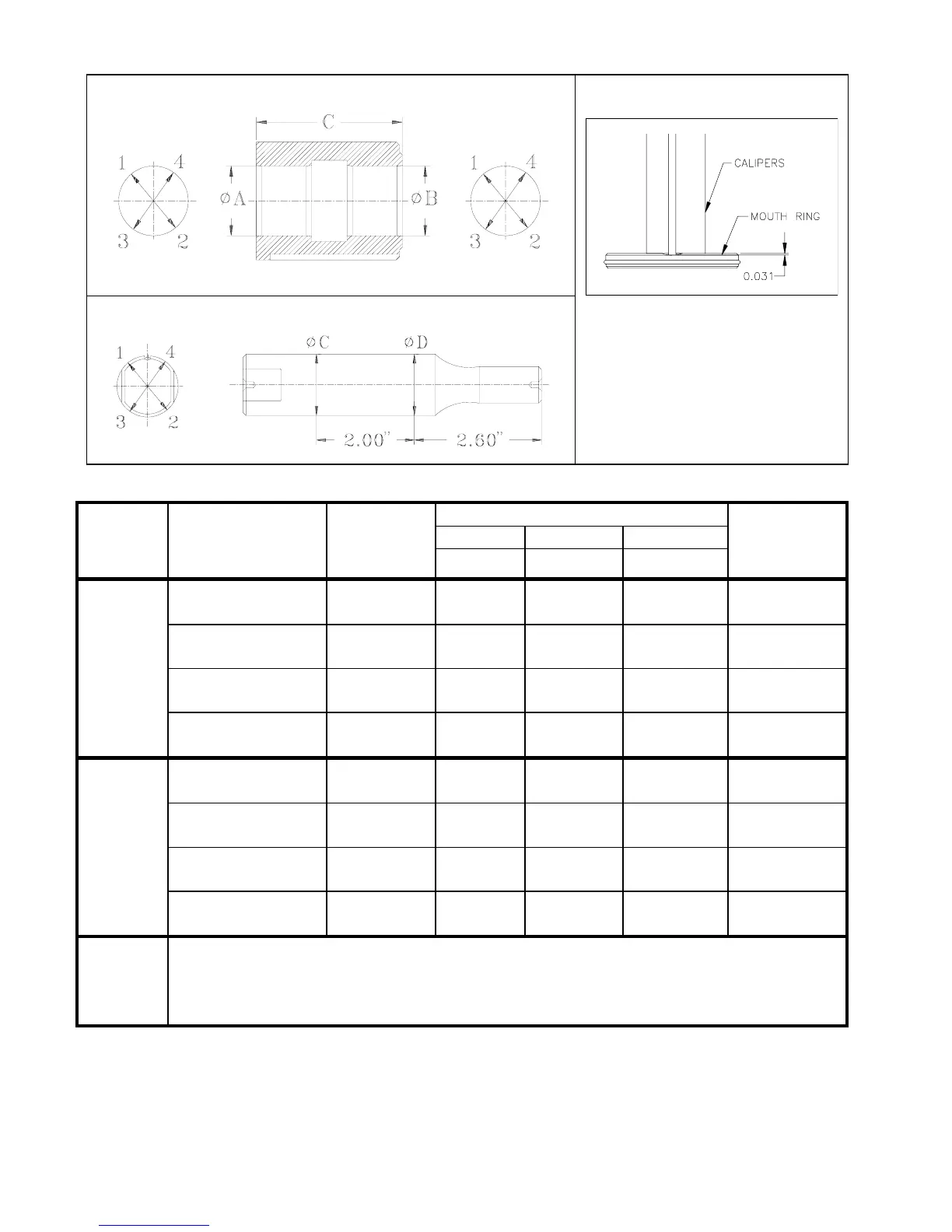

7-c. DETAILED WEAR PARTS TOLERANCES

A) Main bushing C) Mouth ring

B) Pump shaft

Measuring flute depth

Date inspected

DIMENSION

Original

3mo./500hr 12mo./2000hr

Wear

dimension

/ / / / / /

Limits

1.25"

A1-A2 Dia. (in)

(mm)

1.259" dia

3.20 mm

< 1.284"dia

(3.26 mm)

Bushings

A3-A4 Dia. (in)

(mm)

1.259" dia

3.20 mm

< 1.284"dia

(3.26 mm)

B1-B2 Dia. (in)

(mm)

1.259" dia

3.20 mm

< 1.284"dia

(3.26 mm)

B3-B4 Dia. (in)

(mm)

1.259" dia

3.20 mm

< 1.284"dia

(3.26 mm)

1.25"

C1-C2 Dia. (in)

(mm)

1.256" dia

3.19 mm

> 1.250"dia

(3.18 mm)

Shaft

C3-C4 Dia. (in)

(mm)

1.256" dia

3.19 mm

> 1.250"dia

(3.18 mm)

D1-D2 Dia. (in)

(mm)

1.256" dia

3.19 mm

> 1.250"dia

(3.18 mm)

D3-D4 Dia. (in)

(mm)

1.256" dia

3.19 mm

> 1.250"dia

(3.18 mm)

All mouth ring wear surfaces are made with grooves. These grooves provide cooling

Mouth

flow. When new, the grooves are 0.063" [1.60 mm] deep. The minimum groove

Ring

depth is 0.031" [0.79 mm]. Replace when grooves are less the 0.031" [0.79 mm].

* Under normal operating conditions, the shaft should last for many years. When the shaft is subjected to dry running,

thermal stress cracks may develop. If cracks are found, a replacement shaft is necessary to prevent damage to other pump

components.

Loading...

Loading...