11

5. PUMP INSTALLATION

5-a. PIPING

1. Install the pump as close as possible to the suction tank. Pumps are designed to push, not pull,

liquid.

2. Ansimag recommends supporting and restraining both the suction and discharge pipes near the

pump to avoid the application of forces and moments to the pump casing. All piping should line up

with the pump flanges naturally to minimize any bending moments at the pump nozzles.

3. To minimize friction the suction line should have a short straight run to the pump, and be free of

fittings, for a length equivalent to or larger than ten (10) times its diameter.

4. The suction line size should be at least as large as the pump's suction port or one size larger if the

suction line is so long that it significantly affects NPSH available. Never reduce the suction

piping size.

5. The suction line should have no high points since these can create air pockets.

6. The NPSH available to the pump must be greater than the NPSH required. Screens and filters in

the suction line will reduce the NPSH available, and must be considered in the calculations.

7. Caution: Do not install a check valve in the suction line even if a check valve is installed in the

discharge line. The suction line check valve could shut off before the discharge line check

valve closes. This would cause water hammer, which may burst the rear casing /containment

shell.

8. The discharge piping should be equal in size to the pump outlet port.

9. A stop valve and a check valve should be installed in the discharge line. The stop valve is used

when starting and stopping the pump, and to isolate the pump for maintenance. It is advisable to

close the stop valve before stopping the pump. The check valve will protect the pump from water

hammer damage. These recommendations are especially important when the static discharge head

is high.

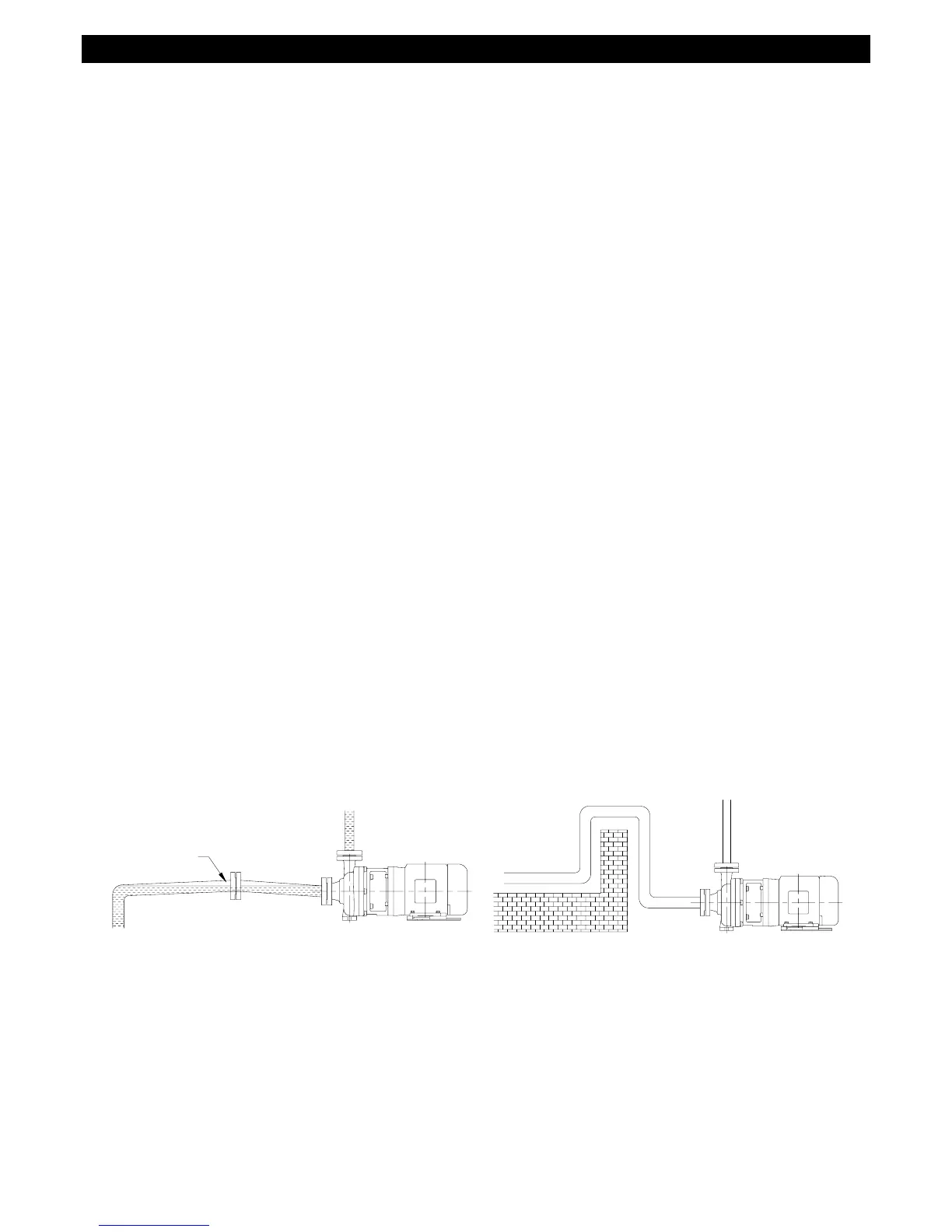

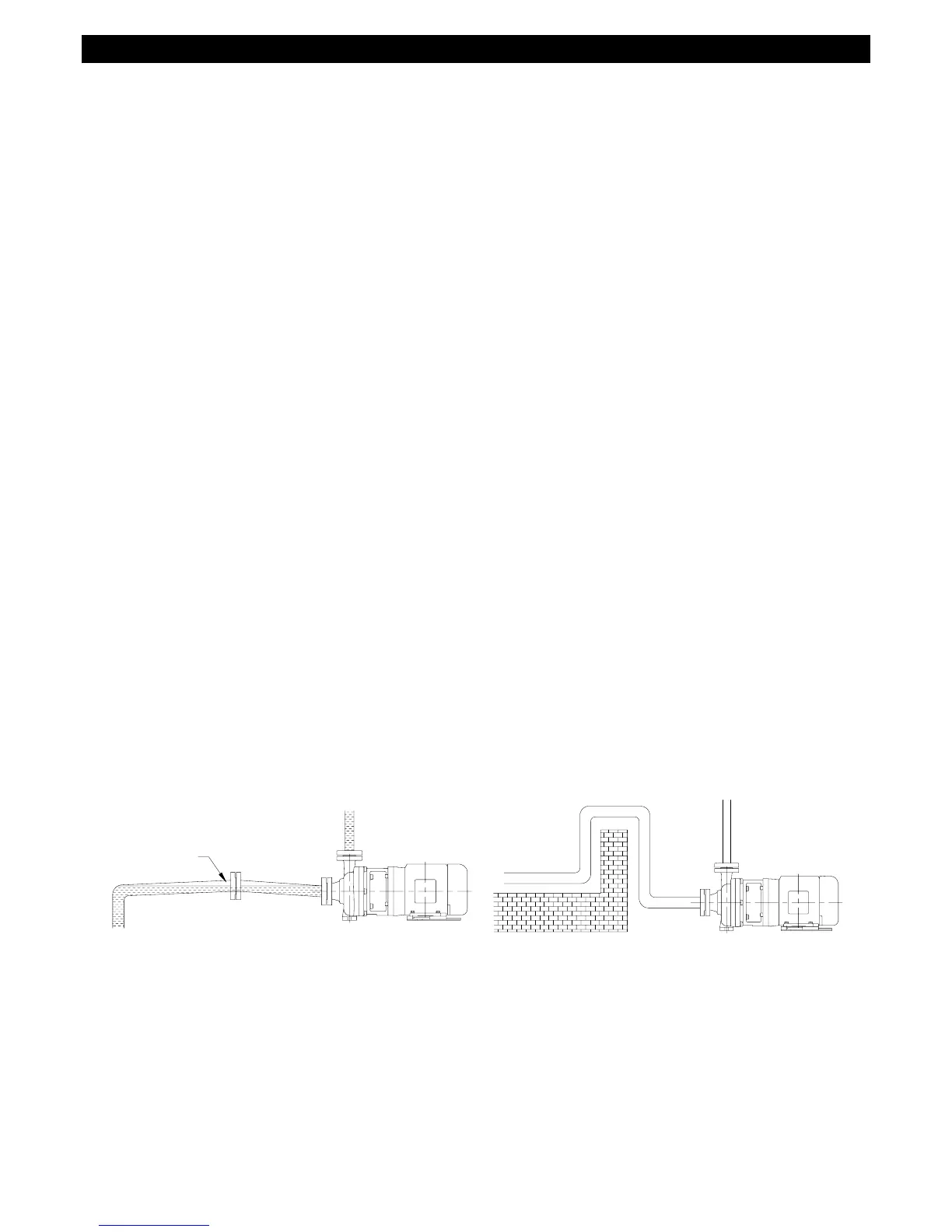

NOT RECOMMENDED NOT RECOMMENDED

Fig. 5-1: Pump Installations

AIR POCKET

Loading...

Loading...