25

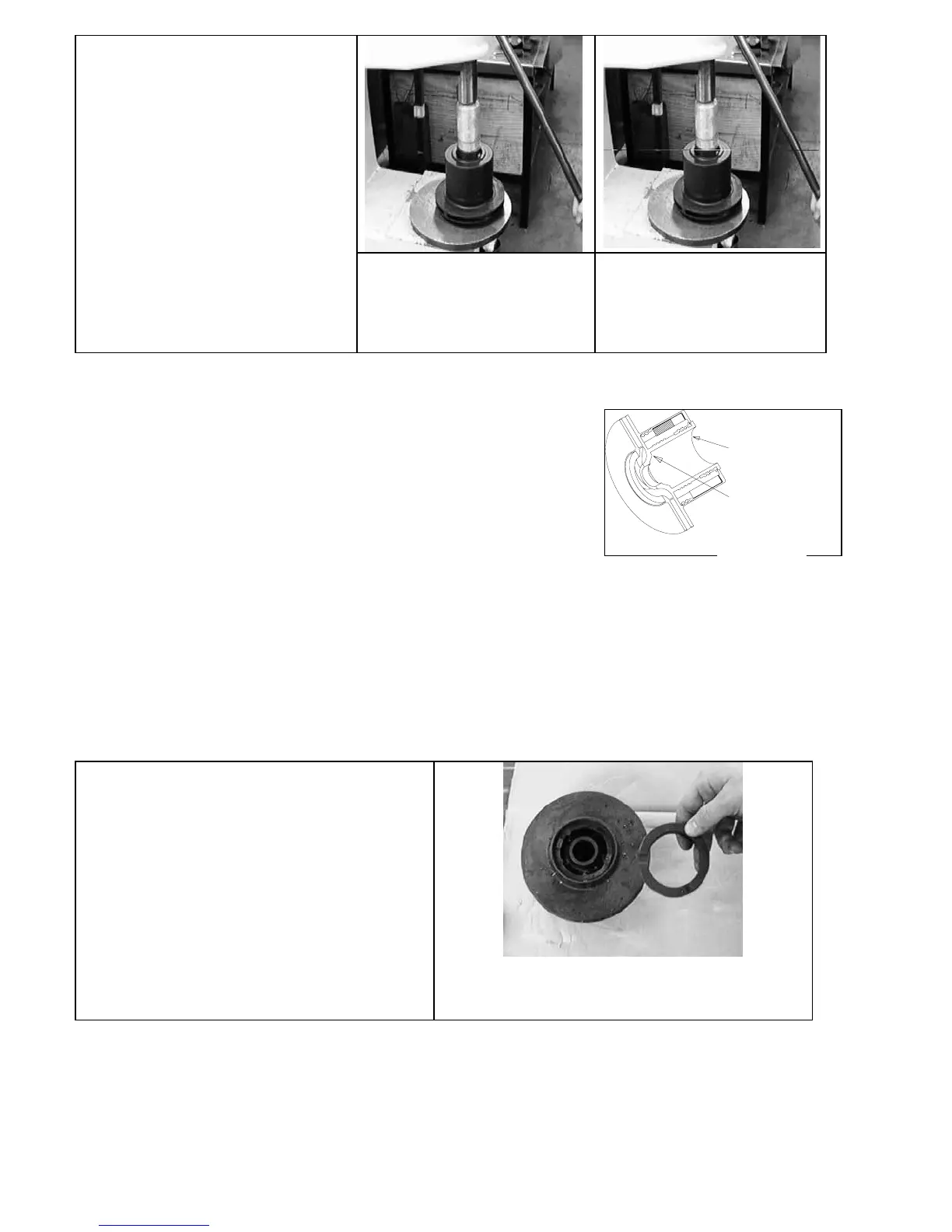

2. Place the supported impeller on

to the bed of an arbor press or

drill press. Using tool (PT0557)

press the main bushing into the

impeller bore. Press until firm

resistance is felt. This will

position the end of the bushing

approximately 0.6" [15 mm]

deep.

Caution: Place impeller

shroud on a circular riser to

protect the lip of the mouth

ring support while pressing in

bushing.

Fig.8-4: Insert Bushing into

Impeller with Arbor Press

Fig.8-5: Insert Bushing into

Impeller with Arbor Press

Caution: Do not use a hydraulic press, since you can not feel

when the bushing hits the bottom of the bore!

Fig. 8-6

NOTE: OLD IMPELLER MODELS have a separate key for the bushing. Place the flat side of the key

into the keyway of the main bushing and line it up with the groove inside the impeller. The cone-shaped

side of the main bushing fits inside the bore.

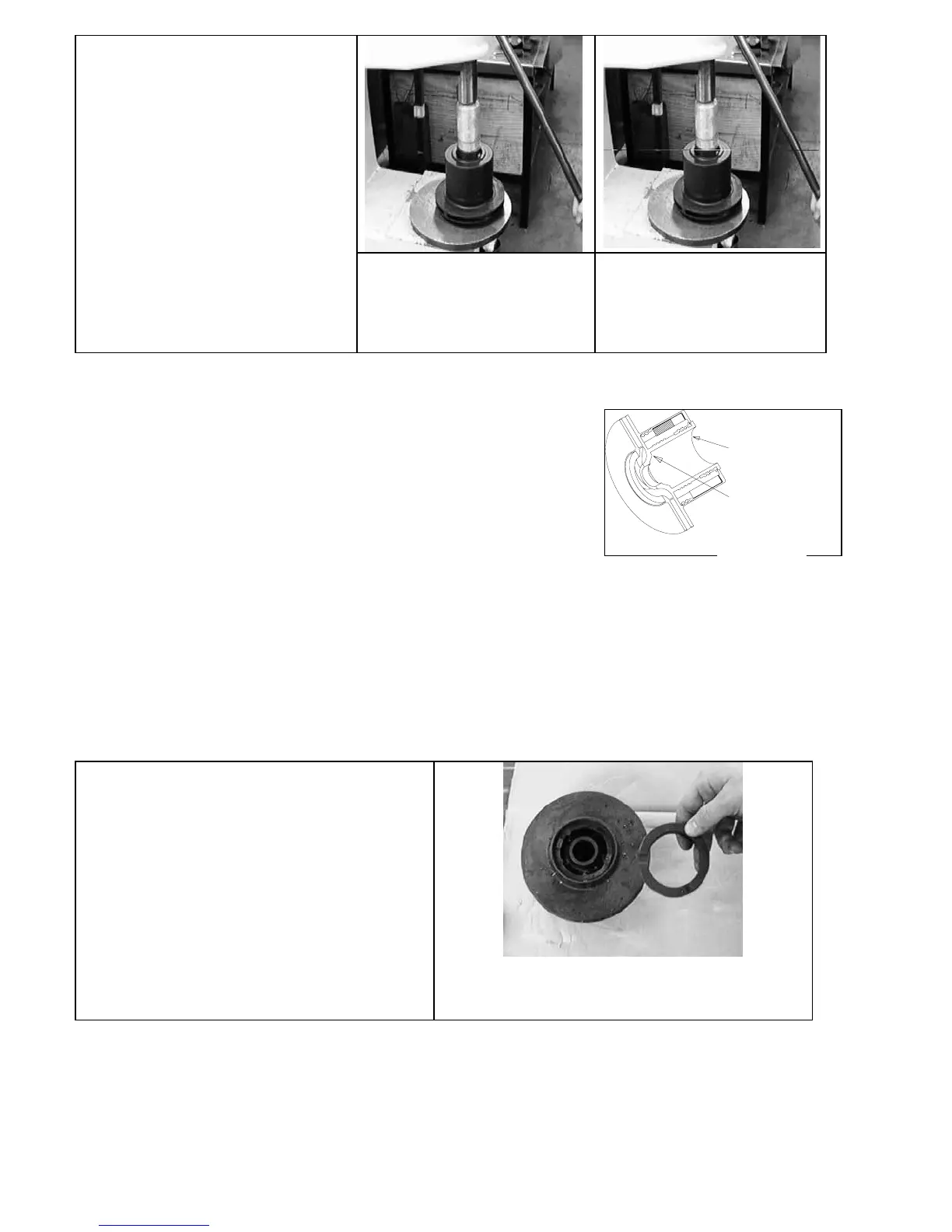

3. Align the notches on the backside of the

mouth ring with the driving “dogs” on the

impeller and press-fit mouth ring with O-

ring attached into the mouth ring seat in

the eye of the impeller. The O-ring is

used as a locking ring. Model K+436,

K+i65160 and K+j65160 do not require an

O-ring.

Fig.8-7: Press-Fit Mouth Ring into Impeller

2-1/8"bore

BOTTOM OF

BORE FOR BUSHING

Fig. 11-4

Loading...

Loading...