19

7-b. INSPECTION CHECKLIST

Since most wearing parts on a mag drive pump cannot be monitored, it is important to inspect the pump

for wear after the initial 500 hours or three months of operation, whichever comes first. Inspect again in

six or twelve months, depending on the results of the first inspection.

Before inspecting, be sure to have a spare casing O-ring on hand to reinstall after the inspection is

completed. To inspect the pump interior, be sure that the pump has first been flushed of all dangerous

liquids.

Operating conditions vary so widely that recommending one schedule of preventive maintenance for all

centrifugal pumps is not possible. In the case of magnetic drive pumps, particularly of non-metallic

pumps, traditional maintenance techniques such as vibration monitoring are not useful or reliable

for wet end preventive maintenance. These techniques are effective only for bearing frames (non-

liquid contact components) and for motor bearings. For best maintenance results, keep a record of

actual operating data such as flow, pressure, motor load, and hours of operation. The length of the safe

operation period will vary with different applications and can be determined only from experience.

The inspection checklist is as follows:

1. Check for cracks in silicon carbide parts such as the thrust ring and shaft.

2. Check for signs of melting or deforming in the shaft support, bushing and the socket of the

containment shell where the pump shaft is held. Dry-running during initial startup or during

operation may cause heat-related deflection or wear of these parts.

3. Inspect the casing liner to be sure there are no signs of abrasion or cuts deeper than 0.05" [1.3 mm].

Liner cracks may occur if the lining is corroded or placed in an extremely cold place, or if a

chemical penetrates the liner and corrodes the outside metal casing. Most liner damage can be

spotted visually. To detect hairline cracks, a 15-20 KV electrostatic discharge tester is

recommended, which is often used to test lined pipe.

4. The 1.25" carbon bushing should be checked for wear and scoring or grooving. The dimensions are

given in Section 7-c. The 1.25" SiC bushing will not exhibit wear under normal operation.

Polishing on SiC surfaces is a normal condition of running and does not require replacement.

However, the inner surface must be checked for cracks, chips or scratches. Verify that the main

bushing is tightly pressed into the impeller. It should be impossible to dislodge the bushing by

hand. Check for signs of melting around the circumference of the main bushing.

Fig. 7-11

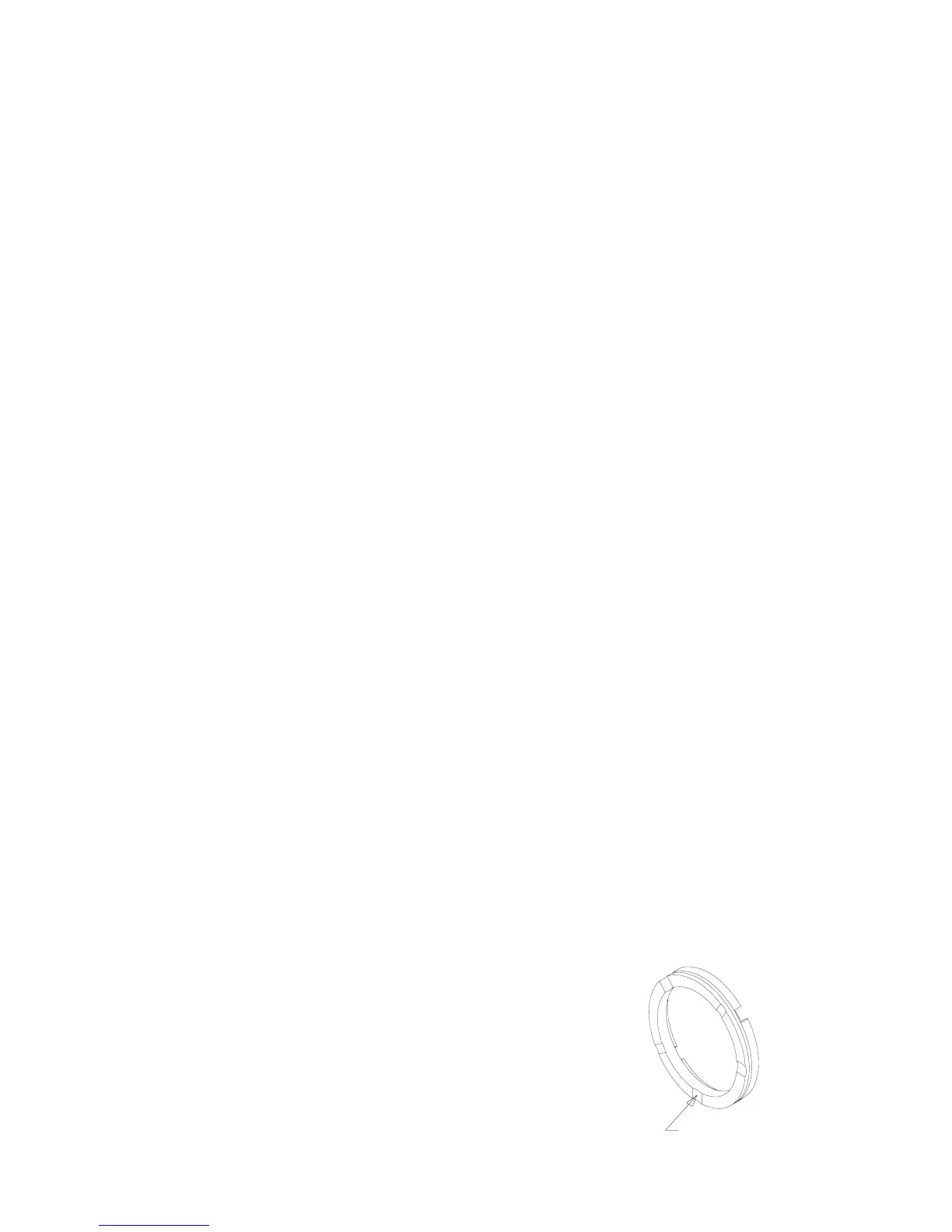

5. Check the mouth ring face for wear. The lubrication flutes are reliable

indicators of mouth ring wear. If they are not visible, it is time to replace

the mouth ring. A part replacement procedure is described in

Section 7-d. If a CFR Teflon® mouth ring is used and excessive

wear is observed, replace it with a silicon carbide mouth ring.

LUBRICATION FLUTE

Fig. 9-1

Loading...

Loading...