4

GENERAL INFORMATION

What is a beam detector?

The XP95 beam detector is made up of a transmitter,

a receiver, an interface and, optionally, one or more

refl ectors.

The trans mit ter projects a beam of modulated infra-red

light to the receiver which converts it to an electrical

signal for process ing in the interface.

The trans mit ter and receiver are mounted so that the

beam will project ap prox i mate ly 0.3m to 0.6m below

and parallel to the roof or ceiling level at distances

up to 100m. The maximum lateral detection range is

7.5m either side of the beam. The interface is usually

installed at ground level.

How does a beam detector work?

When smoke is present in the beam path the light reg-

istered by the receiver is reduced by a level de ter mined

by the density of the smoke.

In the event of the smoke obscuring the light by a pre-

selected minimum level for a period of 8 to 10 seconds

a fi re signal is generated. The detection level can be

set to 25%, 35%, 50% or 65% to suit different environ-

ments, examples of which are given in the table in the

section 'Obscuration Level Setting' on page 6.

Automatic reset

If the beam detector has been in fi re or fault condition

it will au to mat i cal ly reset, once the fi re or fault is no

longer present. After a fi re condition there is a reset

delay of 30 seconds and after a fault a reset delay of

3 seconds.

Automatic signal strength

Over a period of time the light registered by the receiver

might be reduced by factors such as dirt building up

on the lenses of the detector.

The XP95 beam detector compensates for this auto-

matically in order to reduce the likelihood of unwanted

alarms. At the limit of compensation the beam detector

transmits a fault signal. In the event of a fi re being

detected when the beam detector has reached its

compensation limit, the fi re signal will override the

fault signal.

SYSTEM DESIGN

Positioning beam detectors

The XP95 beam detector must be positioned correctly

to minimise the detection time. The detection time

depends on

—the location of the beam detector within the

protected area

—the volume of smoke produced

—the con struc tion of the roof

—the ventilation arrangements

Particular areas where beam detectors should

not be fi tted include:

• spaces where very high levels of ambient

light are present in normal conditions

• areas where excessive amounts of dust,

smoke or water vapour are present as part

of the normal environment

• areas where rapid temperature changes

occur

• surfaces subject to vibration or movement

• buildings in which it is not possible to

mount the beam detector rigidly or align it

correctly

When deciding where to install the beam detector, you

need to think of the construction of the surface you

are fi tting it to and to possible changes as a result, for

example, of changing seasons. These surfaces must

be solid and should not be subject to movement.

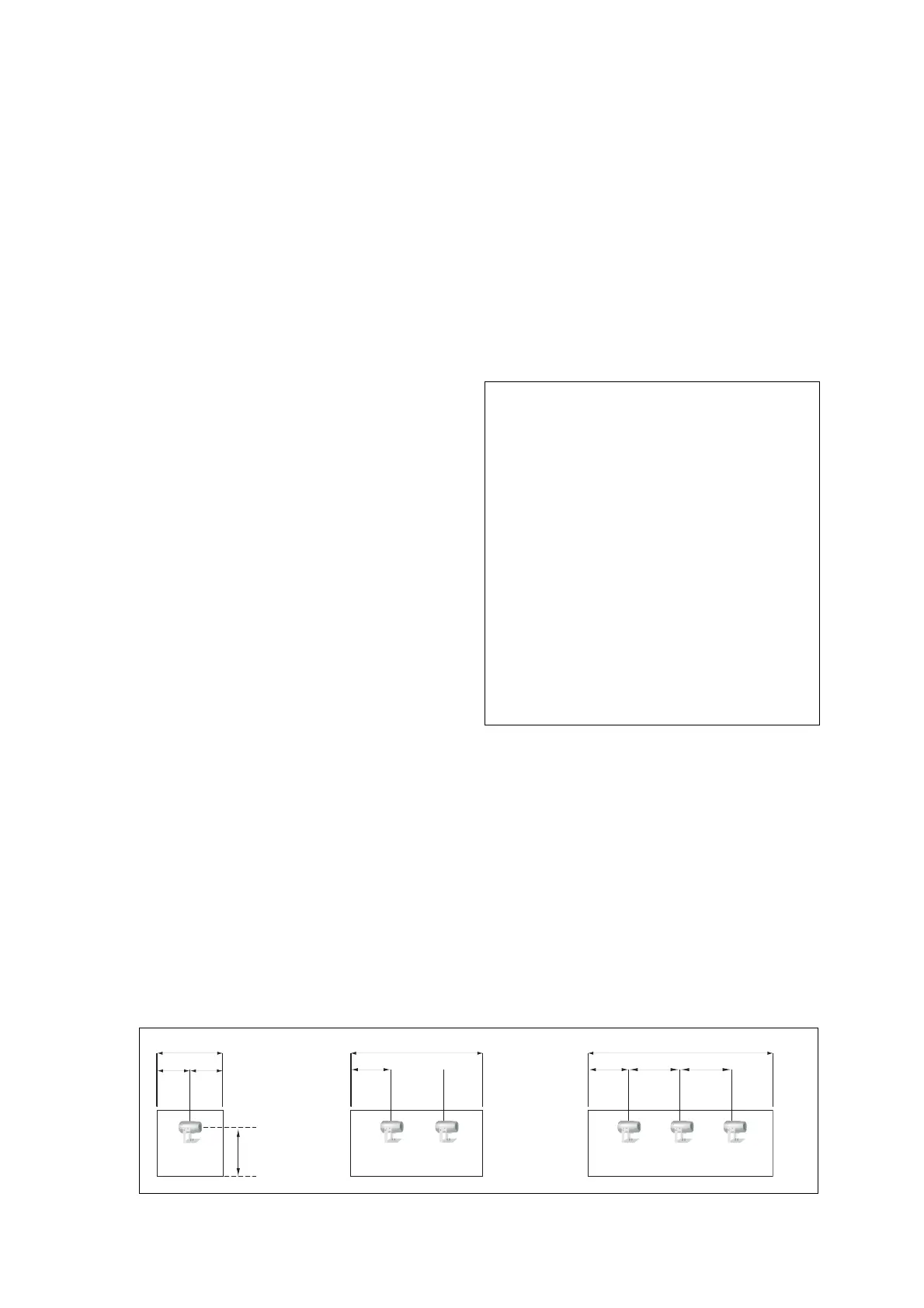

The maximum distance either side of the beam axis

is typically 7.5m for satisfactory detection under fl at

ceilings, providing a maximum total area coverage of

1500 square metres (15m x 100m). The maximum rec-

om mend ed installation height is 40m and the distance

between the beam and the ceiling should be within

0.3m and 0.6m (Fig 1). No more than 3m of the beam

path (measured from the centre of the beam) should

be within 500mm of any wall or partitions.

15m 30m maximum 45m and over

7.5m 7.5m 0.5m

min

0.5m

min

15m

15m

7.5m = max

beam to

wall

distance

0.5m = min

beam to

wall

distance

max = 40m

Fig 1 Positioning detectors under fl at ceilings—examples of three building widths

www.acornfiresecurity.com

www.acornfiresecurity.com

Loading...

Loading...