90

SV200 AC Servo Drive User Manual

920-0096H

2/6/2018

7.2.8 Jerk Smoothing Filter

Applying this dynamic filter on speed and direction signals can significantly smooth motor rotary motion, and minimize wear on

mechanical system components.

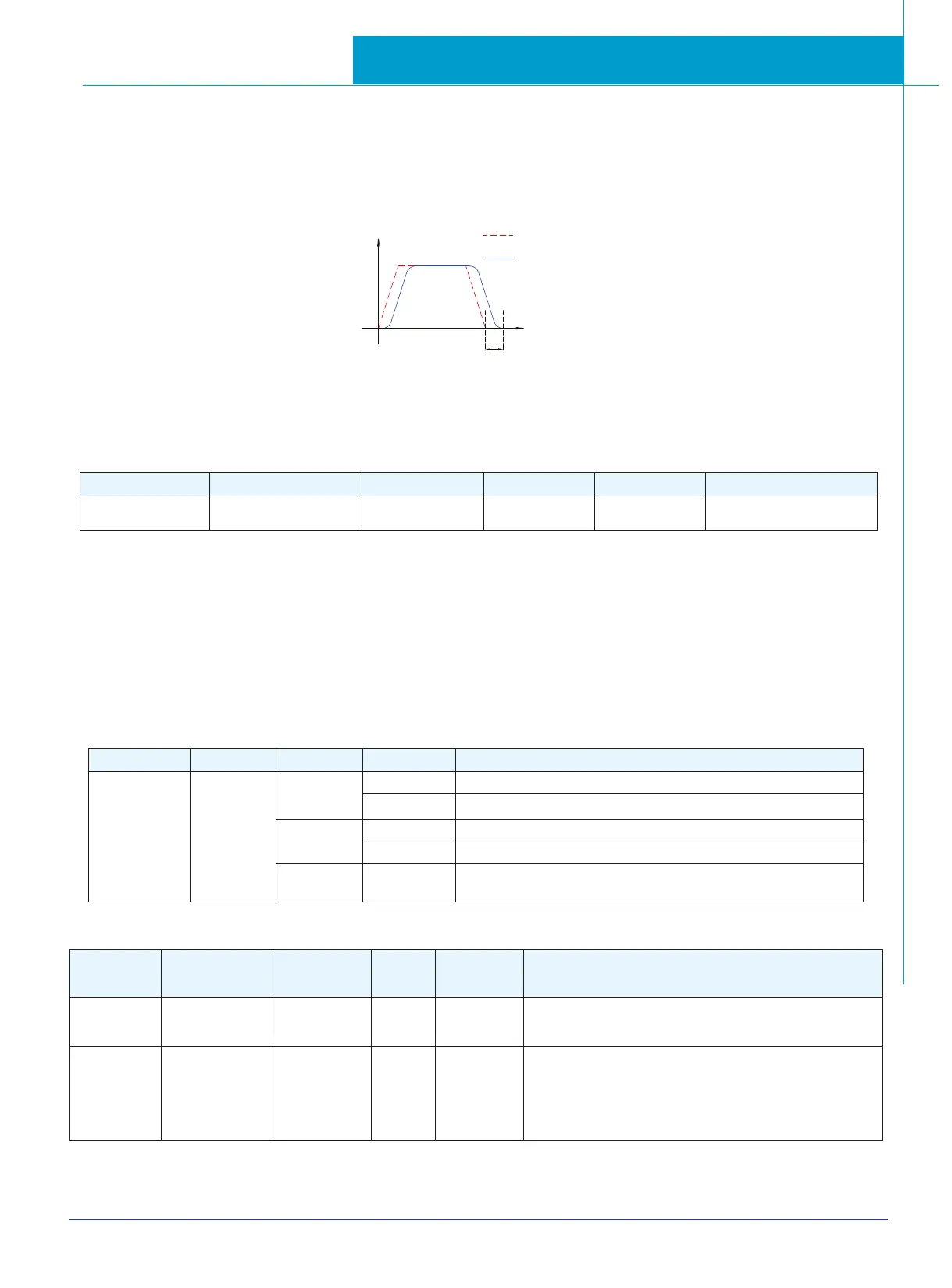

Jerk smoothing filter effects are as follows:

Instruction

Time

Target Curve

Actual Curve

T

1) The smaller value of P-07 (KJ), the stronger the effect it will be.

2) Jerk smoothing filter will cause command delay time T, but it will not effect in position accuracy.

Parameter Setting

Parameter Name Data Range Default LED Display Description

P-07 (KJ) Jerk Filter Frequency 0~5000 5000 5000

Set jerk smoothing lter

parameter

NOTE: Setting to 0, means no filter effect.

7.2.9 In-Position Error Output

In position mode, using the “in-position error output” function can help the user define the motor’s in-position status. When the

difference between drive’s total pulses received and motor’s actual rotating pulse count is within the in position error range, the drive

will send out a motor in position signal.

The forth digit of parameter P-68 (MO) defines Y6 output function. parameter P-46 (PD) defines the in- position error range. P-47 (PE)

defines in position error time duration. If the in position error is within the P-46 (PD) range for more than the time duration of P-47

(PE) setting, the drive will output the motor in position signal.

Signal Name PIN P-68 (MO) Condition Function

Y6

Y6+ (14)

Y6- (13)

5□□□

Closed Closed means motor not in position

Open Open means motor in position

4□□□

Closed Close means motor in position

Open Open means motor not in position

3□□□

(default)

General purpose output, function disabled

Parameters Setting

Parameter Name Data Range Default

LED

Display

Description

P-46 (PD)

In position error

range

0~32000 10 10

This parameter sets the in position error range, when in position

error count is less than the range, drive will indicate motor in

position.

P-47 (PE)

In position

duration count

0~32000 10 10

If the position error is in the in-position range and lasts longer

than the duration time, the motion is considered to be complete

and the motor is in position. If the time value is set to 100 the

position error must remain in the range for 100 processor cycles

before the motion is considered to be complete.

One processor cycle is 250µsec.

Loading...

Loading...