3. MAINTENANCE INSTRUCTIONS

3.1 INTRODUCTION

All the maintenance and gas transfomation operations have to be carried out by qualified

personnel.

Moreover, MAINTENANCE operations have to be made at least once a year and

according to local regulations.

Before winter it is necessary to make the boiler be controlled by authorised personnel to

have an always working system.

Control:

• verify the exchanger cleaning;

• verify the burner cleaning;

• verify the hydraulic system pressure;

• verify the expansion vessel heating system efficiency;

• verify the correct functioning of adjustment and safety thermostats;

• verify the cleaning and integrity of sensor and ignition electrodes;

• control the good circulator running;

• control there are no spills (water, gas smoke evacuation);

• control the gas burner pressure;

• control the combustion output;

• control the emission levels of CO, CO

2

and NO

X

;

• in case of a boiler spare part replacement you should use only original spare parts by

ARCA.

Arca refuses every kind of responsability about every damage caused by the installation of

a non original spare part.

ATTENTION: this boiler has a safety thermostat linked to the chimney draught which starts

to work when there is a combustion product coming back in the ambient. This appliance

has never to be placed out of work. If combustion products come back in the ambient, they

can cause severe intoxications with even death risks.

ATTENTION: after any boiler service regarding the gas pipe system it is absolutely

necessary to control that unions are perfectly running and there are no gas spills.

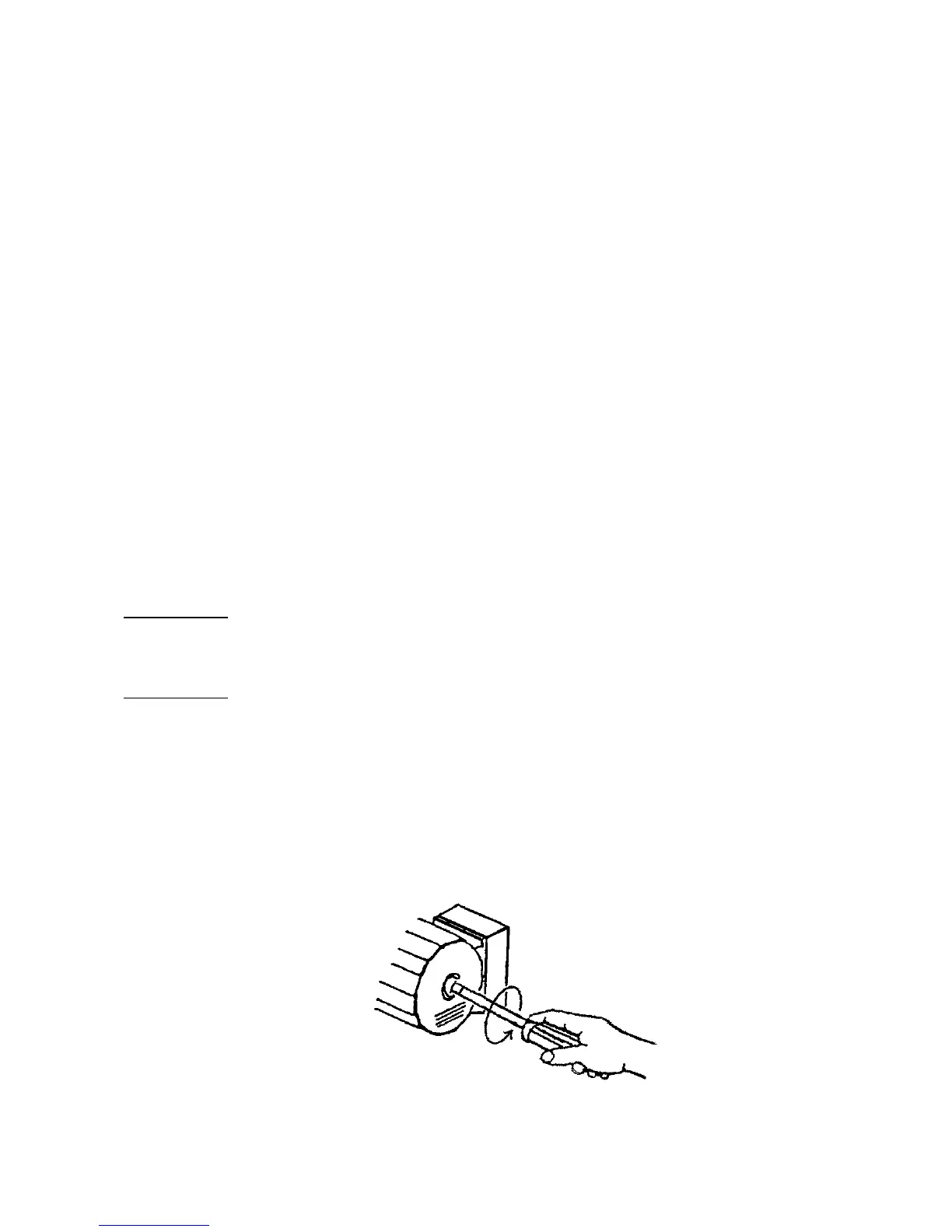

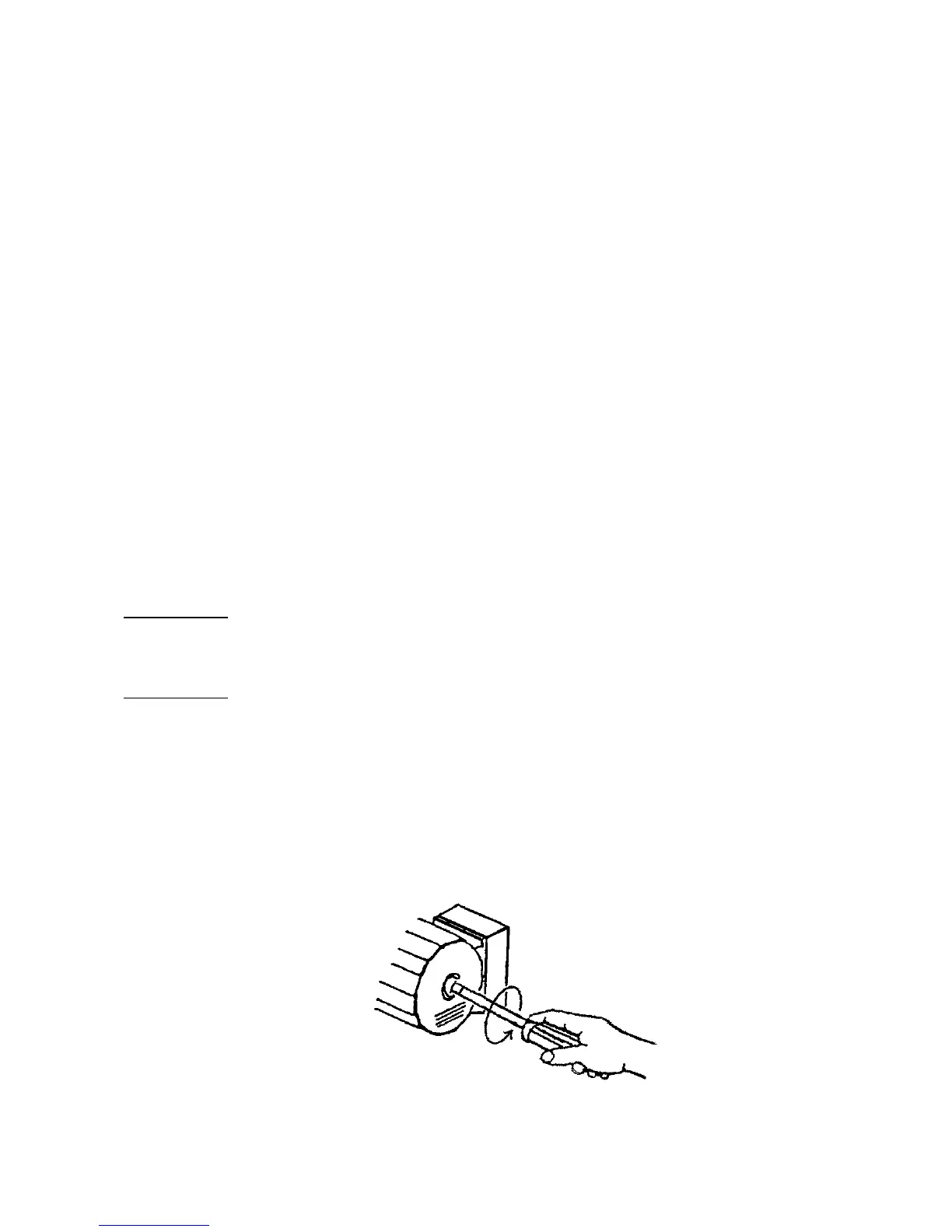

3.2 CIRCULATION DEBLOCKING

When the boiler is new or after a long standstill period you may have a circulator block.

You can comply with this problem as follows:

• unscrew and remove the circulator cap;

• insert the screwdriver and turn it to deblock the circulator;

replace the cap.

25

Loading...

Loading...