16

The correct travel speed keeps the arc at the leading edge of the weld pool allowing the base metal

to melt sufficiently to create good penetration, fusion and wetting out of the weld pool producing a

weld deposit of good quality.

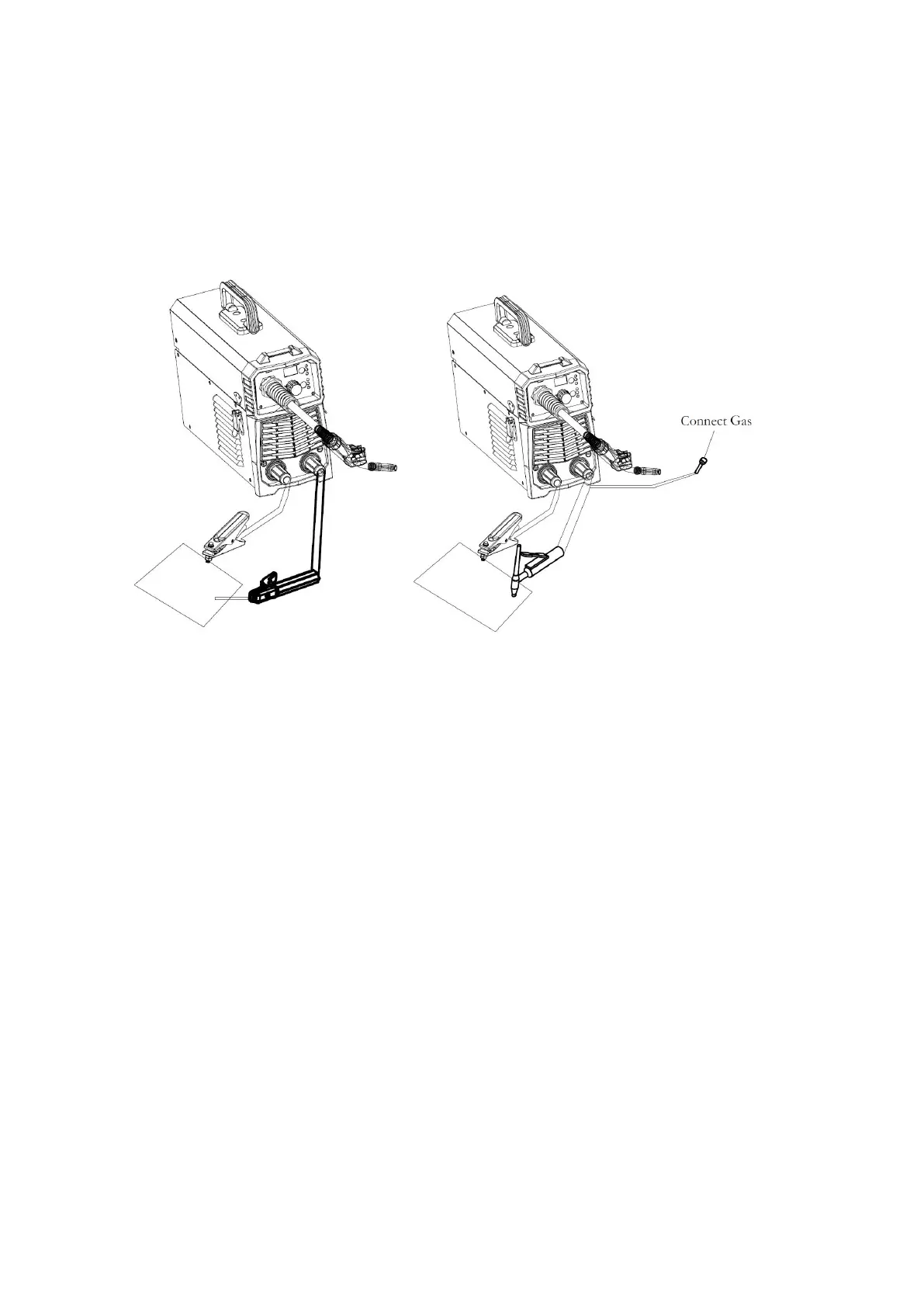

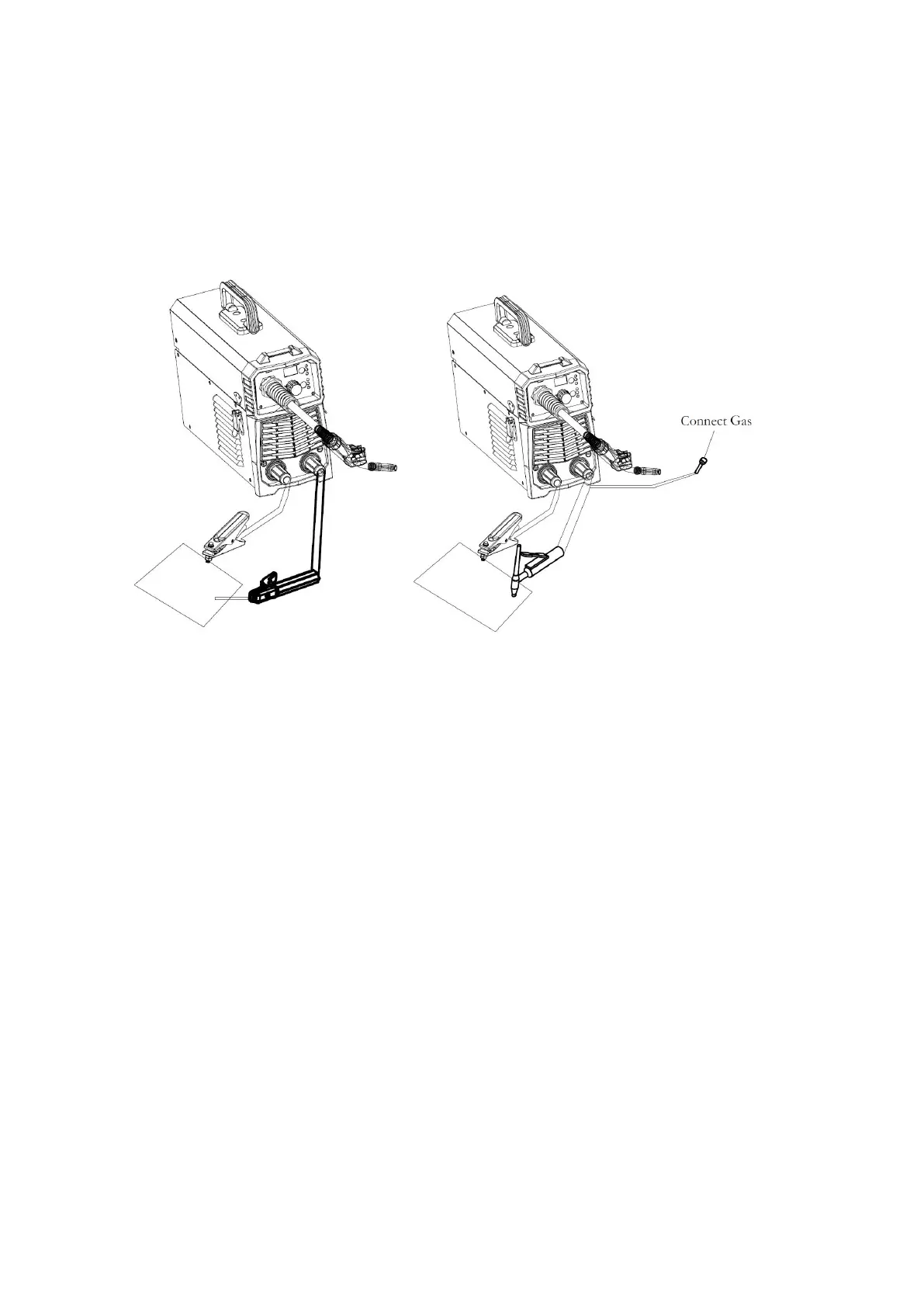

4.5 MMA and TIG Installation

(MMA) (TIG)

1) A primary power supply cable is available for this welding machine. Connect the power supply

cable to the rated input power.

2) The primary cable should be tightly connected to the correct socket to avoid oxidization.

3) Check whether the voltage value varies in acceptable range with a multi-meter.

4) Insert the cable plug with electrode holder into the “-” socket on the front panel of the welding

machine, and tighten it clockwise.

5) Insert the cable plug with earth clamp into the “+” socket on the front panel of the welding

machine, and tighten it clockwise.

6) Ground connection is needed for safety purpose.The connection as mentioned above in 4) and

5) is DCEN connection. Operator can choose DCEP connection according to workpiece and

electrode application requirement. Generally, DCEP connection is recommended for basic

electrode, while there is no special requirement for acid electrode.

7) Insert the cable plug with TIG Welding torch into the “--” socket on the front panel of the welding

machine, and tighten it clockwise.

8) Insert the cable plug with earth clamp into the “+” socket on the front panel of the welding

machine, and tighten it clockwise.

Digital Welder Expert, Know You More

https://www.arccaptain.com

Loading...

Loading...